Results 1 to 10 of 22

Thread: Help.. Electric motor wiring.

Hybrid View

-

04-13-2013, 12:06 AM #1

Help.. Electric motor wiring.

Help.. Electric motor wiring.

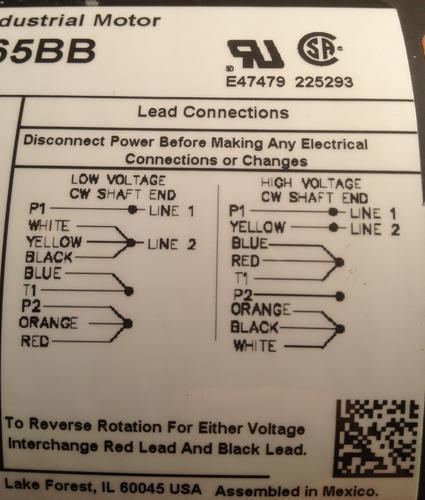

Got a brand new Dayton 1.5hp motor. It has no wiring instructions. Motor has three sets of wires.

First set is "red, blue, and black" they were already twisted together but no wire cap on them. Second set

is "black, orange, and white" they were also twisted together with no wire cap. Then there were four

other wires that were not connected to anything. One is yellow, one is green, and two are black. but one

black wire has writing on it.

-

04-13-2013, 12:09 AM #2

Have you gone to Dayton's website to see if they have any online wiring instructions ? Just a thought. I can't help you myself.

-

04-13-2013, 12:10 AM #3

-

04-13-2013, 12:13 AM #4

I seen images that may have a diagram on the motors label I'll have to check. But I'm no electrician, thats for sure...

-

04-13-2013, 12:34 AM #5'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

The motor can run at one of two voltages--110 or 220--and you connect some of the wires internally (that is, not to the supply power) to connect the appropriate coils. I am an electrician, and have hooked up such motors. Are there numbers printed on the wires? What voltage will you use it at? If there's a plate on the motor, put up a photo of it and I may be able to tell how to hook it all up. I'll look at their website too and see if the info is there.

Best wishes"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

-

The Following User Says Thank You to roughkype For This Useful Post:

officerdread (04-13-2013)

-

04-13-2013, 12:49 AM #6'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

It looks like some of the wires are bundled with zip ties--I think those will be your supply power. The twisted ones are probably set up for lower voltage, but that's not certain. Dayton makes dozens of motors; I can't tell you any more about yours without the nameplate info.

Most industrial settings will run the motor at higher voltage, but you don't get any more speed or power that way. At higher voltage you draw less current to do the same amount of work, so your supply wires don't heat up as much. That means that at higher voltage you can run smaller conductors to supply power to the motor. This saves money in the building's initial construction, especially if the motor is very distant from its supply panel.

From the nameplate info I can tell you what size circuit breaker you should have for the circuit that supplies this.Last edited by roughkype; 04-13-2013 at 12:57 AM.

"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

-

The Following User Says Thank You to roughkype For This Useful Post:

officerdread (04-13-2013)

-

04-13-2013, 12:18 PM #7

I would appreciate any help you might be able to give me. Seeing you are an electrician I'm sure this will be no problem for you to steer me in the right direction. As for the wire tie I put that on there to pull together the four loose wires and keep them separate from the rest. The others were twisted together in groups as I stated earlier.Last edited by officerdread; 04-13-2013 at 02:37 PM.

12Likes

12Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote