Results 1 to 10 of 15

Thread: Plexiglass/Lexan Scales

-

07-11-2013, 05:37 AM #1

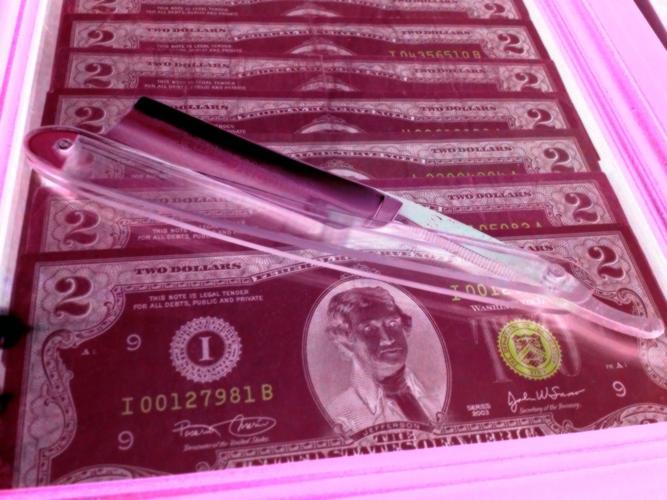

Plexiglass/Lexan Scales

Plexiglass/Lexan Scales

Hey guys, so I just got a Swedish frameback that I am going to restore. It is just a plain blade, and I thought it would look good on some clear Plexiglass/Lexan scales. Let me know what the best way to go about making these are!

Parker"When governments fear the people, there is liberty. When the people fear the government, there is tyranny." Thomas Jefferson

-

07-18-2013, 04:49 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

There are many threads and how-to's on making scales. Search the library. I have been making a few of these lately and it is pretty simple. Make a pattern, cut out the pieces leaving material outside the line, I use very thin 2 way tape to stick them together, drill holes for the pins. When it comes to shaping it all depends on what tools you have and skill level. I shape mine on a belt sander first, and then do the final shape detail by hand with 220 paper. I work my way up to 2000 grit and then polish them up with a rotary tool and white compound which brings them back to shine and clear. I am working with horn right now and considering a vid on doing those. It's basically the same except for the warp factor.

Start here -------> Category:Scale Making - Straight Razor Place WikiGood judgment comes from experience, and experience....well that comes from poor judgment.

-

07-20-2013, 08:28 AM #3He of the unconventional nature.

- Join Date

- Jul 2013

- Location

- San Joaquin County, CA

- Posts

- 58

Thanked: 5

Just throwing my two cents in for any stray novice scale maker that might read this. Lexan would be a durable choice though it is a brand name. Some plastics suppliers refer to the material as polycarbonate or polycarb for short. By no stretch of the imagination should anyone use the typical acrylic plexiglass. Acrylic cracks and breaks very easily. Now polycarb on the other hand is used to make safety glasses, shatterproof windows, and headlight lenses. Tough stuff to say the least. The only downside it that it only comes in one color, clear.

-

07-20-2013, 11:00 AM #4

-

07-20-2013, 12:03 PM #5

-

07-20-2013, 01:23 PM #6

Warp factor, tell me about it !!!

Tired of the Überlather ? Try the Unterlather !

Tired of the Überlather ? Try the Unterlather !

-

07-21-2013, 06:58 AM #7Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

There are also acrylics that you can use. This is what I have made mine out of. Plastic comes in more flavors than ice cream and although some don't care for it others do. I don't think it's such a terrible thing to mix the old with the new. If you look at Double Ducks and their popularity in the day I think the argument falls apart. I bet if they had the choice back then you would find some Wade and Butchers with red mirrored acrylic scales. May sound funny and non traditional but what ever catches your eye is what counts. Just for the record ...I like em either way.

Plexiglass is also a trademark.Last edited by 10Pups; 07-21-2013 at 07:04 AM.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

07-21-2013, 12:24 PM #8Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

I would tend to favor Acrylic/Plexigalss over Polycarb/Lexan. Acrylic comes in a hugh variety of colours, is easy to work with and is much cheaper than polycarb.

Although Polycarb is tougher than acrylic in terms of brittleness and resistance to impact, it does scratch easier than acrylic. Ive never tried polishing it either, but I'm guessing acrylic would polish better too.

Grant"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

07-21-2013, 12:28 PM #9Learning something all the time...

- Join Date

- Jul 2012

- Location

- Central Missouri

- Posts

- 1,690

Thanked: 247

Yup, Lexan scratches quit easily.

-

07-22-2013, 04:36 PM #10

Just a comment about most thermoplastics...plex, etc. If you heat the surface up buffing them, they may crack or break later with no pressure or just a sudden temperature change. Alcohol can change the surface temperature and bing gone. The reason is that the plastic gets internal stress because the surface has a different hardness after heating and the interior does not.

Play with the plastic a bit before you commit to a set of scales. Buff the snot out of a piece and see what happens when alcohol or cold is applied.

Be real careful drilling, The plastic loves to crawl up your drill bit! Hold it to the table with care.

Have fun!

~Richard

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote