View Poll Results: What have you found to be true

- Voters

- 26. You may not vote on this poll

-

Stainless Steel is more difficult

10 38.46% -

Carbon Steel is more difficult

0 0% -

Total myth I find no disernable difference

16 61.54%

Results 41 to 50 of 57

Thread: Stainless Steel vs Carbon Steel

-

10-31-2016, 01:59 PM #41

I don't have a full answer to this, just as I was curious as to where to draw the line of distinction between stainless and carbon steel. In the two examples I gave, they are vintage razors that are fairly resistant to patina or rusting. So maybe that's the difference.

The magnetic razor in question is an old Boeker that has "magnetic" etched on the blade. And the blade literally is magnetic, capable of attracting other steel. Basic honing of it took much longer than it typically would with softer carbon steel.Striving to be brief, I become obscure. --Horace

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

gssixgun (11-01-2016)

-

10-31-2016, 02:02 PM #42

Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

10-31-2016, 02:30 PM #43

Very interesting results on the poll so far. Nobody thinks carbon steel is more difficult, but twice as many people say that there is no difference to those that say stainless is more difficult.

I wonder could the honing medium play a part in the results here? In other words are some stones better for stainless than others?

Perhaps that is a different topic, if so I am sorry and please feel free to ignore this question.Fact: Opinions are not the same as facts... Well, that's my opinion anyway

-

The Following User Says Thank You to Porl For This Useful Post:

gssixgun (11-01-2016)

-

10-31-2016, 02:41 PM #44

I think it is a good question. As I mentioned in a previous post, that ATS-34, and the S30-V I honed needed a diamond plate to set the bevel, and synthetics to finish the job. I would say, IME, some high carbon also benefit from synthetics, depending the hardness. Sometimes it is too much of a good thing.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

10-31-2016, 02:49 PM #45Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,331

Thanked: 3228

My 1911 was not a Colt's made 1911 but from AMT called the Hardballer . Yup, I was given to understand that was the same problem as with the Colt version. The solution was to use two dissimilar stainless alloy to prevent galling or load the crap out of it with lithium grease. Even with dissimilar stainless steels there still may be problems with a pistol built to tight specs as in target pistols. Then again tight carbon steel target pistols can be temperamental in operation too. Nature of the beast I suppose.

BobLife is a terminal illness in the end

-

10-31-2016, 09:50 PM #46

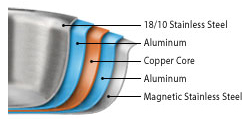

Speaking of magnetic stainless, just ran into this All-Clad cookware advert, note the 'magnetic stainless' on the exterior for the newer induction cooktops :

(The illustration displays a cross section of one All-Clad Copper Core pan)

Very difficult to hone though ......... impossible to set a bevel .......... Be careful how you treat people on your way up, you may meet them again on your way back down.

Be careful how you treat people on your way up, you may meet them again on your way back down.

-

10-31-2016, 10:40 PM #47

One of the first stainless pistols was the Ruger Security Six series which came out around 1974 and the cylinders would jam up because of expansion of the metal. I know because I had one and they finally replaced the pistol because the original one kept having issues the more I used it. They had a big contract with the Border Patrol and didn't want the issues to become widely known.

I've said this before but I find some carbon steel razors to be way more demanding to hone than any stainless ones. But in general a stainless razor might take a few more strokes but that's about it.No matter how many men you kill you can't kill your successor-Emperor Nero

-

The Following User Says Thank You to thebigspendur For This Useful Post:

gssixgun (11-01-2016)

-

10-31-2016, 10:59 PM #48

While I don't have Thousands of razors under my belt I do have several hundred and I also have 4 Friodur's that I use regularly.

I thought that it was 'just me' in that when honing my Friodurs they seemed to take quite a lot more time. I found this true when I honed other Friodurs that were sent to me by others.

Then one day I was reading a thread about whether or not SS was harder to hone than plain carbon steel and a member stated that 'they don't take any longer than carbon steel blades' and a cantankerous old fart who lives in the boonies of Northern Idaho replied: "Oh yes they are".

I didn't feel so bad after that! Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

gssixgun (11-01-2016)

-

10-31-2016, 11:57 PM #49

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

gssixgun (11-01-2016)

-

11-01-2016, 12:58 AM #50I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

The Following User Says Thank You to mainaman For This Useful Post:

gssixgun (11-01-2016)

104Likes

104Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote