Results 11 to 20 of 25

Thread: Rubberset restore

-

10-01-2016, 07:31 PM #11

Excellent info ,thanks again Mike!

I remember the drying/curing rack in your post, Ill be using that idea. Ill study up some more on setting the knots in these, was wondering about the space between the plug on the base of the knot and the inside of the rim of the cap, seems like a perfect spot for corrosion to start. It may not be a factor, since the brushes dry pretty quickly, but has me wondering if I should coat that inner rim with something first to seal the inside of the cap before placing the knot.

Yes, that 2x72 is a great machine to have, you will never regret that investment. I do all kinds of metal/wood work and I use that thing all the time, very versatile machine. I highly recommend a variable speed set up also, big big advantage over a single speed motor.

I have his EF-48 in the shop also, a 2x48 horizontal grinder/sander that is also a huge time saver.

Harrywally,

very interesting , I have been looking over that ebay link ... DOH!! I hope they are not the same knots lol

I am going to look into theses a bit more. They look pretty darn close if not the same. I was reading on another board where they were comparing the TGN HMW to this knot and most were giving the nod to the Envy as far as density and overall quality which is why I went with these. Time for some more reading. Thanks again for the info.

-

10-01-2016, 10:58 PM #12Junior Member

- Join Date

- Feb 2014

- Posts

- 1

Thanked: 0

Those knots will look fantastic in those handles.

-

10-02-2016, 12:58 AM #13

Thanks for the post...sweet looking brushes and nice work

Keep it safe and Cheers,

Jer

-

10-02-2016, 01:50 AM #14

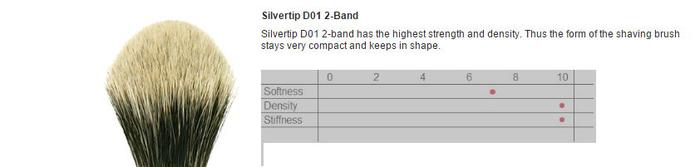

Interesting - maybe this is something new on Shavemacs site, but I'll give them credit for it, I don't recall seeing this before.

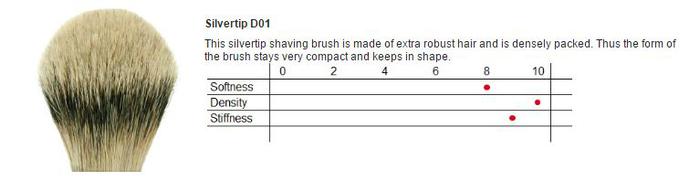

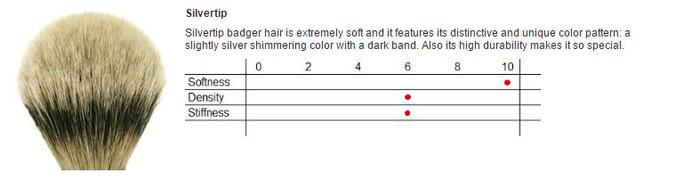

There are ratings now around the knot characteristics, so you have an idea of what you're getting - superb thinking.

Here is the D02

Here is the D01

As you can see, both the D01 and D02 are high on density and stiffness, with the D02 the stiffest of them all - that's the next knot going into a project Mike is once again helping me out on....thanks Mike.

Whereas the Shavemac Silvertip, can clearly be seen to be a knot for those wanting a softer tipped brush with less stiffness.

Great work from the people at Shavemac...wish all the brushmakers would follow suit....5 Stars for Shavemac!Last edited by Phrank; 10-02-2016 at 01:52 AM.

-

The Following 2 Users Say Thank You to Phrank For This Useful Post:

HARRYWALLY (10-02-2016), Hirlau (10-02-2016)

-

10-02-2016, 02:59 AM #15Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,465

- Blog Entries

- 1

Thanked: 4207

That's a new scale, but I haven't been on their site for a while.

Very useful tool, and pretty accurate I'd say as far as the differences in attributes for the various knots.

Nice.

Phrank's next project can double as a back scratcher when not being used for shaving..

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

Phrank (10-02-2016)

-

10-02-2016, 03:21 AM #16

Excellent info Phrank!!

That D01 has my name on it! Thats the ONE.

-

10-02-2016, 03:30 AM #17

I'm going D02 for the next project, two "10's" on stiffness and density - yehaaa! Thank the Lord above Mike is here to once again come to the rescue!!!

That D02 is stiffer and denser than the D01, I think I will be in brush heaven, as the D01 is superb....there's many name brand brushes back in their boxes on the shelf due to that Shavemac....

-

10-02-2016, 02:49 PM #18

No more progress yet, But have used the brush a few more times and am loving the Envy knot.

Here's a couple quick pics. Taylor of old Bond st. sandalwood this morning.

Temp brush stand, momma is thrilled... I have some nice curly maple that may be put to use for a proper shelf soon, but for now any metal surface will work. Small magnet for the win!

Will recess some washers in the bottom of the shelf for drying/hanging the brush.

Custom baby !!Last edited by AKmik; 10-02-2016 at 03:42 PM.

-

The Following User Says Thank You to AKmik For This Useful Post:

Hirlau (10-17-2016)

-

10-03-2016, 04:12 PM #19

Added another to the mix. This is another #3, was in fugly shape when it arrived. This one will take a bit more work but should turn out great, the deepest pitting is where there is plenty of meat to work with, and the cap and trademark look good with minimal corrosion.

After some work I have most of the pitting and corrosion taken care of and can start getting everything smoothed out. Need to run for some more sandpaper, but here is where it is at.

Also note the loft difference on the pair of #3s.

Slow going , but fun project.

-

The Following User Says Thank You to AKmik For This Useful Post:

Hirlau (10-17-2016)

-

10-04-2016, 07:53 PM #20

Here's what I have come up with for knot removal. quick and stinky.

Sorry boar guys.

Had to do it. The serrated blade on my EDC was the quickest way to get rid of these old boar knots.

Again flattened the face on the 12" disk sander for a flat surface to drill.

Strap wrench to help keep fingers in their current configuration during the drilling process.

Once drilled I just chipped away the glue from the top.

Time to sand .

I have ordered a couple more knots to compare with the Envys . Got a pair from TGN their silver tip grade A , and HMW, also grabbed the V Sheng equivalents , I want to give theses all a good look,try, and see whats up.

Looking for the best quality knot short of the Shavemac. Also e mailed Elite Razor to see about his offerings.

If a $60 knot can be had for $20 I'm going to see, and if one of theses is more to my liking I will see that too. I will post up my comparisons here.Last edited by AKmik; 10-04-2016 at 07:56 PM.

-

The Following User Says Thank You to AKmik For This Useful Post:

Hirlau (10-17-2016)

82Likes

82Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote