Results 1 to 10 of 68

Thread: Few restorations/modifications

Hybrid View

-

09-26-2014, 01:42 AM #1

Most impressive

-

09-26-2014, 03:49 PM #2Member

- Join Date

- Dec 2013

- Location

- Warsaw, Poland

- Posts

- 80

Thanked: 48

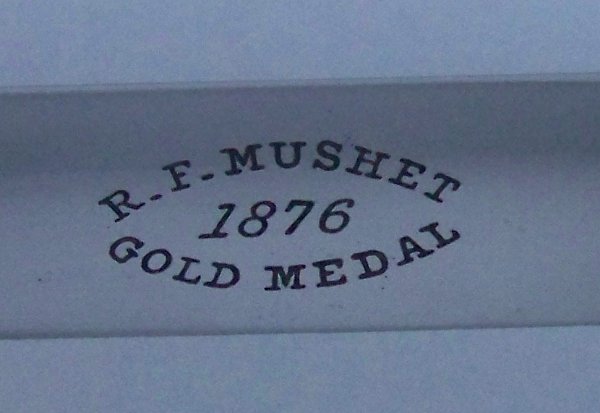

I hope so, below presentation of my last (so far) restoration will explain my idea of eching improvment.

Straight Razor: Samuel Osborn & Co. Clyde Steel Works from Shefield

Original scales : ivory (cracked unfortunately)

Before:

During operation:

Firstly I mask eching or stamp area by nail varnish.

After few minutes can start remove varnish in places intendent for eching. I made it with magnifier and using small needle. Character by character whole stamp or eching mus be uncovered

After that arduous job, I put FeCL3. Wait about 15 - 20 minutes. It depends on concentration of mixture.

And achieved black and deep eching.

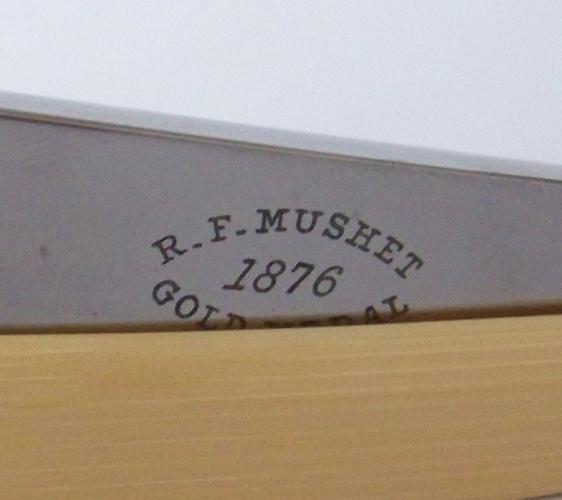

Before this method, I try electrolise (5volt supplier and brine) but this proces gives worse efects.

Like this:

Before, few characters vanished completely and had to reconstructed.

My MOSSTAMP razor was improved only by eching. This Sam Osborn by combine those two metods.

Actually I don't use electrolise.

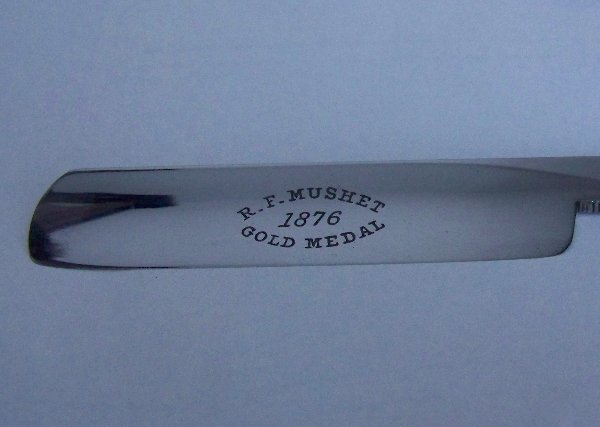

After restoration:

Scales: Bamboo finished by polished CA. It's my way for ivory replace

Pins: Stainless steel

Wedge: Piece of coin

Last edited by Lewy; 09-26-2014 at 04:10 PM.

-

The Following 17 Users Say Thank You to Lewy For This Useful Post:

1oldDago (08-31-2016), ajkenne (12-31-2015), dislocatedmoral (06-11-2016), dwCNY (01-08-2016), Geezer (12-12-2015), jmercer (12-12-2015), KindestCutOfAll (04-10-2015), ovidiucotiga (08-17-2017), Pithor (04-11-2015), Renspen (10-02-2014), RezDog (10-02-2014), Sandycrack (10-03-2014), sharptonn (09-27-2014), Slawman (06-11-2016), Substance (01-21-2017), WW243 (04-09-2015), xiaotuzi (08-12-2016)

-

09-26-2014, 04:20 PM #3

Makes ya want to cry. Such meticulous work, such a good result. Bravo, dear sir, bravo!

"The sharpening stones from time to time provide officers with gasoline."

-

09-26-2014, 04:27 PM #4

That is a great technique for the etchings and overall beautiful work.

*Insert deep thought/profound statement here*

-

09-26-2014, 09:40 PM #5

Very nicely done

Great write up on the processSaved,

to shave another day.

-

09-26-2014, 10:57 PM #6

Thank you Lewy! A great technique and fabulous workmanship!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

09-27-2014, 01:20 PM #7

im not sure i understand. so you

1. coat the area with nail varnish

2. scratch out the etch (what you want more defined is now 'exposed')

3. mask the varnished area with tape

4. put on a few drops of FeCL3 (which is what exactly?)

5. wait 15-20 minutes

6. wipe off and finish sanding an polish

is this right? i think i might want to use this method

also fantastic restos by the way! i am very impressed

-

04-09-2015, 05:22 PM #8

-

04-09-2015, 06:12 PM #9Member

- Join Date

- Dec 2013

- Location

- Warsaw, Poland

- Posts

- 80

Thanked: 48

Jemmo, these are new bamboo scales, because I didn't know how to fix this crack

-

04-10-2015, 03:35 AM #10Senior Member

- Join Date

- Jul 2014

- Location

- Pennsylvania

- Posts

- 100

Thanked: 36

Wow, amazing work!!!

128Likes

128Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote