Results 11 to 20 of 41

-

02-20-2015, 03:28 PM #11

That's very nice. I've been taken with MOP lately and have some black in the post right now. I was only able to get 42mm so it will be 4 per side for me.

My service is good, fast and cheap. Select any two and discount the third.

-

The Following User Says Thank You to UKRob For This Useful Post:

PierreR (02-20-2015)

-

02-20-2015, 03:31 PM #12

Beautiful razor, very creative.

-

The Following User Says Thank You to Bayamontate For This Useful Post:

PierreR (02-20-2015)

-

02-20-2015, 05:17 PM #13

I will correct this... WIP coming

So this is something I have been thinking about, redesigning, and picking away at now for quite some time.

My thoughts behind this was to do a frameback in the truest sense of the word. I was thinking that in the glory days of straight razors, real high quality steel may have been in short supply, and to keep as much as they could, the frameback may have been born. Utilizing a lesser steel for the frame, and their very best for the edge, a smith could spare his resources along a little further.

I thought about making a simpler build, but I figured, hey, I will use the best I have! I haven't pulled all the punches before!

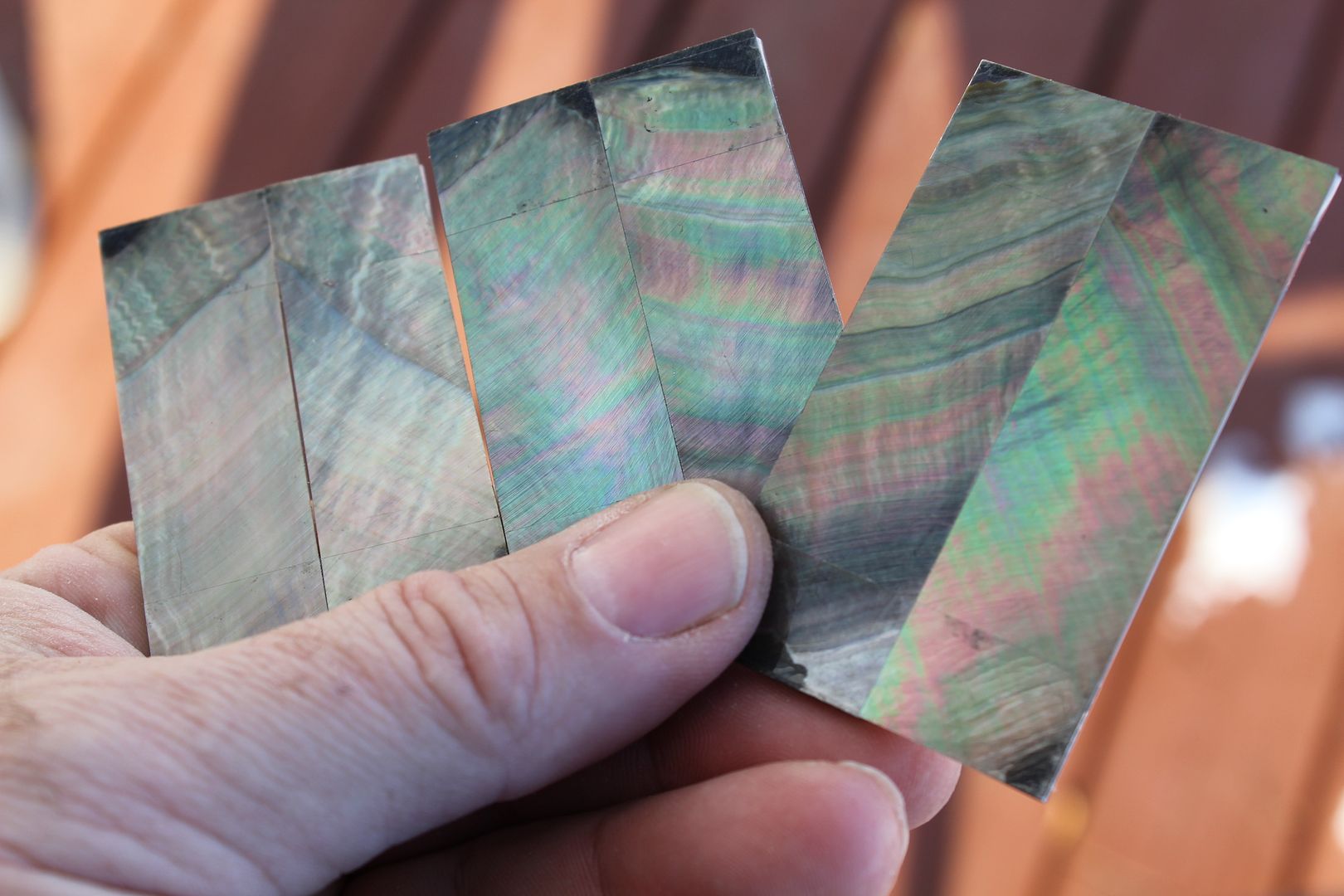

I was thinking kinda in bits and pieces, and accumulated the items I would like to use over a month or two. I have used this material in the past, and liked it, but I wanted to hold out for AAA grade Black Lip Mother of Pearl!! I found some, and ordered it up!

Next, was the frame and how to treat the spine. I decided I would use a hardenable steel, so the wear while honing would be more even. I chose 52100 carbon, its a ball bearing steel. I cut it to shape, milled the channel to accept the blade, and bent it to shape. Sorry no pics of that process.

For the blade, I chose a piece of fossil damascus, that I was going to use for a knife, but figured, as I mentioned, I would use the best I had., I rough ground, and fitted the blade, in the frame.

Now on to file working the spine, polishing, and heat treating the frame.

Then trimming and final fitting the blade, finish grind, and test etch. More on this later. Will be adding a barbers notch.

For the handle frame, I wanted metal, but not the weight, so I ordered in some titanium, cut it out, and manually surface ground it thinner.

Frame was cut out, both pieces CA'ed together, and profiled.

I had a bit of a brainbuster, trying to think of a way that I could attach the border strips, between the tiles of pearl. I didnt want to rely on epoxy, so I figured out a mechanical means to attach them. Then began fitting the tiles of pearl. Bit by bit, nice and easy...

Last edited by PierreR; 02-20-2015 at 07:10 PM.

My friends call me Bear.

-

-

02-20-2015, 05:57 PM #14

Over the top! I love it! The main reason I am impressed with it is that it has a very reasonable blade shape and I would love to shave with it. Sharp corners and old hands do not make great shaves.

The scale work is exceptional and i do know how hard it is to keep MOP together...Lovely!

Thank you!

~RichardLast edited by Geezer; 02-20-2015 at 07:26 PM.

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

PierreR (02-20-2015)

-

02-20-2015, 07:17 PM #15

Once the tiles were fitted, I profiled, shaped, and put them through grit progression. Here are some sneak peeks! The fire in these tiles are outstanding!! Tomorrow I want to have both scales pinned, So there is no chance the epoxy can fail, and have the blade sorted out. Maybe a decision on the wedge.

A little less accomplished than I had hoped today, but this is it so far. Finished up the scales, pinned and polished. Re-etched the blade, and fixed in the frame.

My friends call me Bear.

My friends call me Bear.

-

The Following 5 Users Say Thank You to PierreR For This Useful Post:

Baxxer (02-21-2015), Bordee (02-21-2015), williamc (02-23-2015), Wolfpack34 (02-20-2015), WW243 (03-07-2015)

-

02-20-2015, 07:21 PM #16

-

The Following 9 Users Say Thank You to PierreR For This Useful Post:

Baxxer (02-21-2015), Bordee (02-21-2015), Geezer (02-20-2015), randydance062449 (02-22-2015), RezDog (02-20-2015), Substance (02-21-2015), Wolfpack34 (02-20-2015), WW243 (03-07-2015), yardie (02-24-2015)

-

02-20-2015, 07:50 PM #17

Outstanding...Stunning...and all the other adjectives as well! Really wonderful Bear...

Lupus Cohors - Appellant Mors !

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

PierreR (02-21-2015)

-

02-20-2015, 09:23 PM #18"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

It will be interesting to see how the nickel contributes to wear on the hones at the edge compared to the pattern welded material. What percentage powder did you use?

-

02-20-2015, 10:25 PM #19

Less than the 2% that is standard in the 15N20 steel used in the pattern welds. This piece tested with a HRC of 60.5 (Give or take .5)

My friends call me Bear.

-

02-21-2015, 12:05 AM #20

That is an absolutely stunning frameback razor and a testament to old world craftsmanship.I have a Wade & Butcher frame back and I know how well framebacks shave. You sir have a talent that most of us could only dream of possessing. Congratulations on your achievement! If you ever decide to make this a buisness, pm me and I will be your first customer.

Pete <:-}"Life is short, Break the Rules. Forgive quickly, Kiss Slowly,

Love truly, Laugh uncontrollably, And never regret ANYTHING

That makes you smile." - Mark Twain

-

The Following User Says Thank You to petercp4e For This Useful Post:

PierreR (02-21-2015)

91Likes

91Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote