Results 21 to 28 of 28

Thread: Jaques LeCoultre rescaled

-

03-25-2015, 03:41 PM #21

Yes it does. Could you please give me a peak to peak dimension at the top of five threads? That way i can figure the thread count to go to a clock repair shop and find a couple. ( distance peak to peak /number of points = threading.)

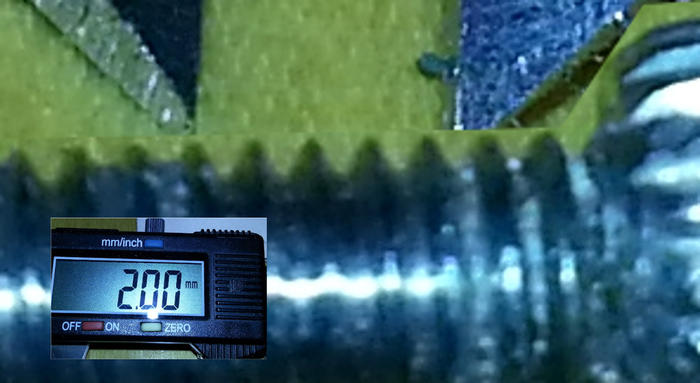

As I read it now the thread is ~ 2.5x 0.4

Thank you!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

03-25-2015, 04:46 PM #22

@Vaga

How many layers of tape did you use when honing?

TIAOldTraf

Mind the toe, and the heel, 'twill follow.

-

The Following User Says Thank You to OldTraf For This Useful Post:

vaga (03-25-2015)

-

03-25-2015, 04:56 PM #23

Looks fantastic, I don't think it could be better.

-

The Following User Says Thank You to MandoRob For This Useful Post:

vaga (03-25-2015)

-

03-25-2015, 05:23 PM #24

-

The Following User Says Thank You to vaga For This Useful Post:

Geezer (03-25-2015)

-

03-25-2015, 06:05 PM #25Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Richard,In your travels,look for a watchmakers Screw plate (are very common and cheap) with brass you can make all sorts of micro screws.

Ton of them on the bay.CAUTION

Dangerous within 1 Mile

-

03-25-2015, 06:18 PM #26

@vaga

Your blade looks bigger (wider, less wear) than any of my le Coultres or clones of it. Guess I will need to use trial and error - Sharpie and one layer, adding another layer until I hit the optimum bevel. (unless anyone a better method?)OldTraf

Mind the toe, and the heel, 'twill follow.

-

03-25-2015, 09:20 PM #27

-

03-25-2015, 10:56 PM #28

Thanks vaga! ~Thanks Pix,

I have a few screw plates left over from Jewelery making, and a bunch of taps & dies from machine shop work. and so far none do the correct thread.

Looks like it should be 1.8/5= .36 to .4 as a lead. so the 2.5 x .35 or.4 should be possible. Will check out my stash of screws and taps and dies. And then go to a clock maker! Gun smith didn't have any that worked at all.

Thank you!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote