Results 1 to 10 of 45

Thread: Tamahagane work in progress

Threaded View

-

04-01-2015, 01:01 PM #1

Tamahagane work in progress

Tamahagane work in progress

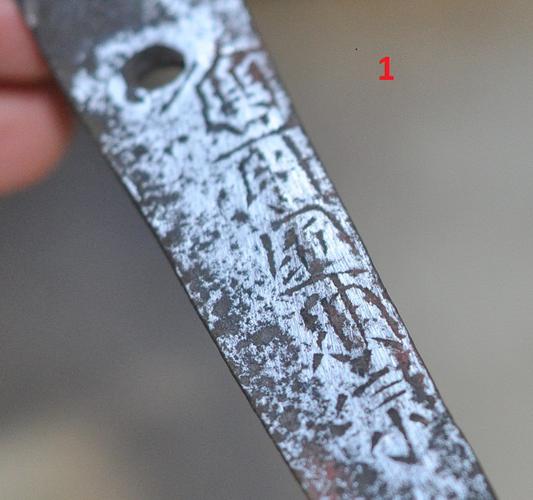

Some time ago I was asked to build 2 Tamahagane razors, made from the nakago (tang) of old Japanese blades. I have 4 pieces to work with. This project is different from my previous tamahagane build in a couple of ways. First, this is not edge steel, but nakago. Second, because of that, I cannot retain the original heat treatment and hamon, simply because there isn't any. A nakago is never fully hardened.

This means that I need to do the heat treatment myself. these are the 4 pieces.

Initial spark testing confirmed that none of them was hardened in full. To verify that they were all good steel, I brought them all to cherry red and quenched in water. There was a bit of warp (to be expected without normalization and unknown heat / deformaiton history) and all of them sparked well afterwards.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

180Likes

180Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote