Results 11 to 14 of 14

Threaded View

-

08-21-2015, 07:31 PM #1

Antique Tamahagane razor work in progress

Antique Tamahagane razor work in progress

This one is the 2nd razor I am making from the 16th century sword.

This piece came from a lower part of the sword, so it was a bit wider, allowing for an easier grind. And of course, the fact that I have worked with this material before helps. Grinding differentially hardened steel is a challenge. It is very similar to grinding suminagashi, so that helped as well. It is pretty jumpy on the grinding wheel. Only difference is suminagashi is easily replaceable, and this isn't.

First I cut the correct part from the sword.

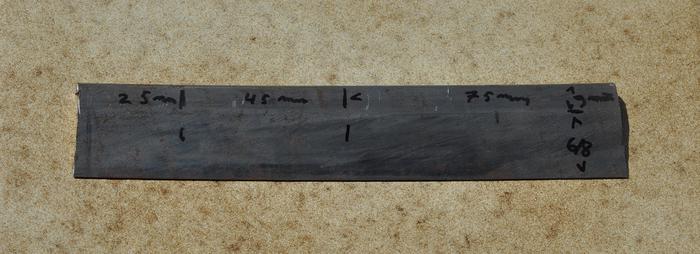

Closeup of the blank

Rough outline of the razor. No detail yet, just the outer shape

During grinding, the hamon came out. This is also where grinding became a true challenge.

This is with the hollows ground to final shape.

And this is without lighting, but with the areas marked that I want to grind down. The spine has to be made less wide. And I have noted where I would make a thumbnotch. I can also make a shallow fingernotch on top of the tang, between the tang and the spine. But that has yet to be confirmed.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

lz6 (08-21-2015)

44Likes

44Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote