Results 1 to 10 of 27

-

12-21-2020, 11:50 PM #1Senior Member

- Join Date

- Feb 2020

- Location

- Red Deer, Alberta

- Posts

- 246

Thanked: 10 Westor Bros Anchor Brand Restoration

Westor Bros Anchor Brand Restoration

I just finished this today. All I need to do is hone it and shave with it.

Anyway here it is. I realize that the camera never lies. The horizontal scratch lines look awful up close. I did this all by hand and realize I should have used my Greaseless compounds on the wheel. I can't believe how awful the pins look close up under the camera lens. I gotta fix that. The wedge was glued in place and when it opened the wedge split but thankfully nothing broke off the wedge and I was able to glue the toe back into it's original position.Also, the area around the right hand side pin is a mess. The scales look to me like they were dipped in a shiny lacquer or glaze for the final finish. I'm not sure how to fix that other than trying some gloss lacquer.

All comments and suggestions welcome.

Thank you all.

-

12-22-2020, 02:07 AM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Nice work. Greaseless is a double edge sword. It is aggressive but can easily wash out crisp lines and sharp corners.

Better to hand sand out stria by alternating your sanding directions in the lower grits. Sand in one direction with a backer, until all the previous directional scratches are removed.

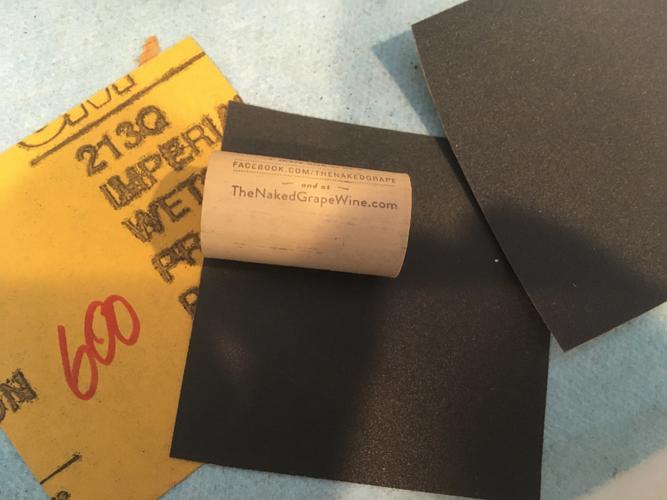

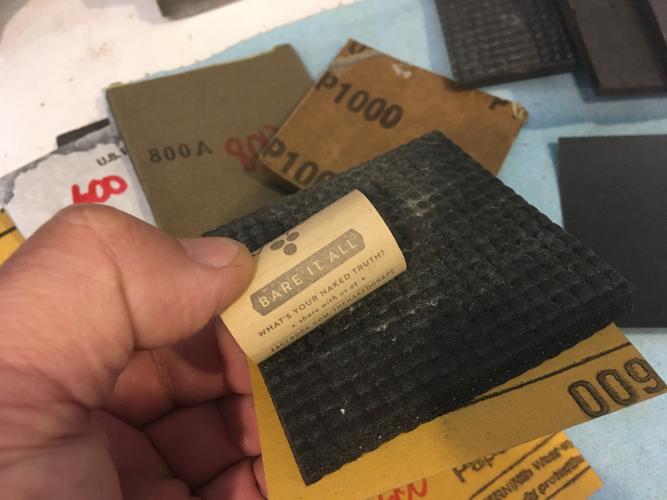

I use a synthetic wine cork, wrapped in a 3x3 piece of 6mm craft foam or yoga mat. Yoga mats come in a variety of thickness and durometer which can produce different finishes and more importantly hand grip that can aid tremendously in hand cramping comfort. I also cut my sandpaper to 3x3 pieces to use the entire piece, just rotate a quarter turn for a fresh side. Quality sandpaper is cheap and does make a difference.

If you remove all the scratches then switch directions, using quality paper and switch frequently to fresh cutting side, you will get a better finish in a shorter time.

Once you take it to 600 or 1k finish you can polish by hand or buffer with compounds, I like Green Stainless and White finishing on a loose wheel.

You can buff the pins smooth with Green Stainless compound and sewn wheel. Go slow with lite pressure, alternating directions.

-

12-22-2020, 04:25 AM #3

Man relax. You apologize too much. I think it looks pretty good! The things you pointed out could improve a little but you're aware of it so just go till you're satisfied. What you've done so far looks good and I think if you take Marty's advice it will be outstanding. I love those Wester Brothers blades and yours looks in good shape. Look forward to the SOTD with it.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

12-22-2020, 02:04 PM #4

I hope that came across the way I intended. I think you're doing fine. I too am my own worst critic sometimes but that is a good thing. We have all been a beginner. You have shown persistence and an eagerness to improve and that will pay off. In the end, unless you are selling razors or restoration services, you are the only one who has to be satisfied. It is good to strive for better but it sometimes sounds like you are beating yourself up over detail. If you don't have a deadline then just keep working at it until you're happy. I have razors I have gone back to multiple times to do modification or rework improvements. I think your work gets consistently better so I would suggest cutting yourself more slack. If it's a hobby then enjoy it. It defeats the purpose of having a hobby if you don't.

One word of recommendation. If you don't already have some get some 3M Marine Metal Polish. Especially for hollow ground blades where your room for sanding is limited it goes a long way to cleaning up and shining a blade without having to worry about scratches. It can be used on a wheel but I prefer rubbing by hand with a rag. That avoids rounding off the lines. It just keeps the angles clean and crisp.Last edited by PaulFLUS; 12-22-2020 at 02:06 PM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

12-22-2020, 03:27 PM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,395

Thanked: 4821

There is a shop on ebay that has great collars for pinning with.

https://www.ebay.com/sch/ajkenne4xm3...88.m1543.l2654

There are a couple of others. These collars have great shipping prices to Canada and are great quality.It's not what you know, it's who you take fishing!

-

12-22-2020, 10:28 PM #6Senior Member

- Join Date

- Feb 2020

- Location

- Red Deer, Alberta

- Posts

- 246

Thanked: 10

Hey Paul, I'm sorry man. I'll try to relax more!!

Oops, dang. lol

Hey Marty, anyway you can take a picture of your wine cork rig and post it? I understand what you're saying but like the saying, 'a picture paints a thousand words'.

Hey Rez, are those to be used instead of washers? or do my washers go underneath the collars then peen away?Last edited by theoldguy53; 12-22-2020 at 11:02 PM.

-

12-23-2020, 01:05 AM #7Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,771

Thanked: 551

-

12-23-2020, 04:41 AM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,395

Thanked: 4821

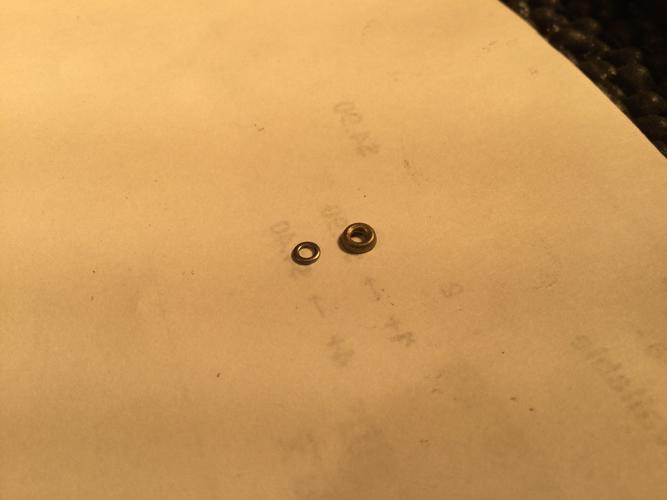

Often tiny washers go under the collars. The washers you are using are too big to go under the collars.

Here is a collar and washer example.

And this is what it looks like peened

For more perfect peening of collars there are many examples by Sharpton, in the what are you working on thread and several others. He is pretty much a master on the subject.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

markbignosekelly (12-23-2020)

-

12-23-2020, 01:25 PM #9Senior Member

- Join Date

- Feb 2020

- Location

- Red Deer, Alberta

- Posts

- 246

Thanked: 10

Thanks Rez, I'm going to order some of those and look up the posts by Sharpton on peening of collars.

As an aside, you are correct, this is a hobby for me that I gain a lot of enjoyment out of and the learning of new things ads to that enjoyment.

I have no intention of selling or becoming a seller of restored razors. What I really enjoy is taking a piece of old history and watching it come alive again after a hundred years or more wondering who shaved with it, where they lived, what they did. And the ultimate satisfaction of honing it up and being able to say, "Oh ya, that was an awesome shave!

-

12-23-2020, 09:49 PM #10Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here are several pieces of 6mm craft foam and Yoga mats cut to 3x3. I also cut my sandpaper to 3x3.

A synthetic wine cork is 1.5 inches, roll the paper around the cork and roll it a ¼ turn to sand on new grit.

Once you use up the grit on each side, you can rotate the 3-inch paper 4 times and use all the grit on each piece.

I work on a 9x11 sheet of 6mm craft foam covered with a blue paper shop towel. When you press a razor onto the foam the edge sinks into the foam and allows you to sand up to the edge. You can literally sand away the bevel safely to the edge and the razor will not move.

If you want to sand a razor without un-pinning it. Use 2 pieces of 6mm craft foam, supported by the blade and tang. The scales open at 90 degrees so the blade fits between the two 3-inch pieces of foam.

A synthetic wine cork is denser than a real cork and most importantly is cut flat on the ends, which allow you to sand up tight to a corner.

Wrapping the cork with 6mm foam makes a larger sanding backer that contours to the blade shape and is much more comfortable to hold for an extended period.

-

The Following 4 Users Say Thank You to Euclid440 For This Useful Post:

DZEC (12-24-2020), jfk742 (01-31-2021), markbignosekelly (12-23-2020), planeden (12-23-2020)

79Likes

79Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote