Results 11 to 18 of 18

Thread: Brittain Wilkinson & Brownell

Threaded View

-

05-18-2021, 05:57 PM #1

Brittain Wilkinson & Brownell

Brittain Wilkinson & Brownell

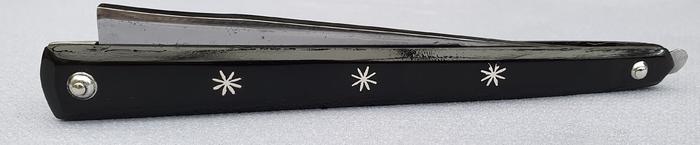

Restored this today "Brittain Wilkinson & Brownell". ("France" Tang Stamp) It is a "Dip-at-Toe" 1780 ish.

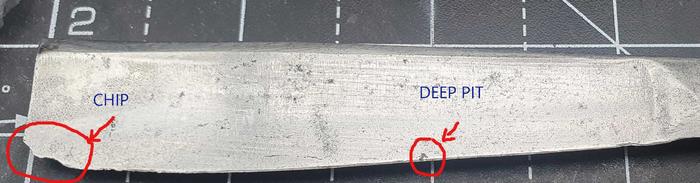

It has a satin finish and Silver collars. To be honed tonight. I made sure it has a pretty bevel.. It did have some severe chips at the toe end and a nasty pit on the edge. I have grinded it so that the pit should fade away with a 1k bevel set.

Cheers

65Likes

65Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote