Results 1 to 9 of 9

16Likes

16Likes

Thread: Making a cracked Genco into a shortie

Threaded View

-

01-18-2025, 10:16 PM #1Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,814

Thanked: 563 Making a cracked Genco into a shortie

Making a cracked Genco into a shortie

I guess I got a bit confident fitting purchased horn scales to a shortened blade. This time I crafted my own scales.

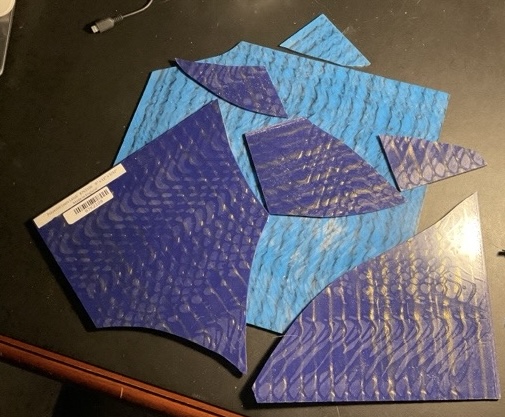

I used a polyester material from Lee Valley they claim can be worked like wood. It comes in sheets about 1/8? thick, so I didn?t have to thin it - a bonus since I don?t own a belt sander. I did discover it is a tad brittle, especially when subjected to freezing temperatures in a UPS turck for a weekend before delivery.

They quickly sent replacement sheets packed with much more robust padding at no charge to replace the fractured pieces. I was greatly impressed with their customer service.

Even at room temperature, it was still brittle. My first attempt shattered while using a jig saw and when peening.

Eventually, I covered both sides with painter?s masking tape before cutting the pattern and drilling the pin holes.

I have a photo of an intact Clauss with the shortie for comparison.

This was my first attempt at building scales, so I used a spacer rather than a true wedge. Had to leave something for the next project.

FYI - the colour I used is called ?lapis lazuli?.David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote