Results 1 to 10 of 30

Thread: WIP Straight Razor

-

04-28-2011, 07:59 AM #1Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32 WIP Straight Razor

WIP Straight Razor

I shave me since 2 year with straight razor. I tried a lot of time with various success to make some razor. I succeed 2,5 time to make one really efficient. For the last one i did i take picture.

I used a 100MnCrW4 (O1) 5,9 thick plate. I draw the blade. It will be a simple 5/8. I cut with a stainless steel cutting disk.

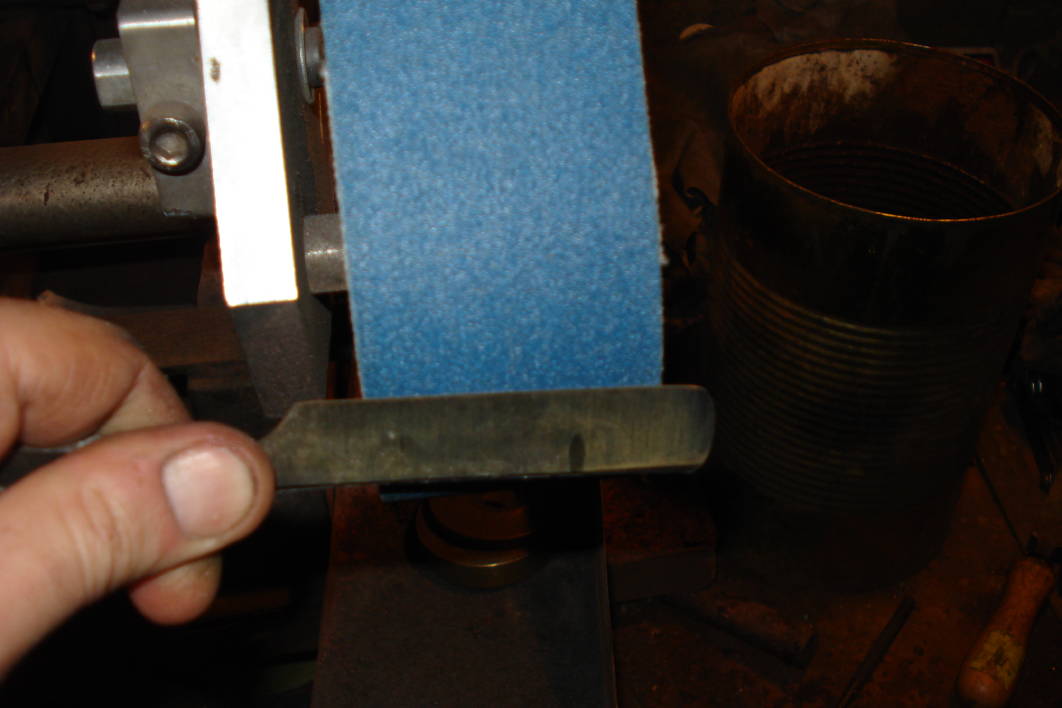

Some 60 belt grit grind after.

The shape is more or less OK

I drilled the pivot hole to 3,8mm

I reamed the pivot to 4mm

The blade is drilled.

-

-

04-28-2011, 08:00 AM #2Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

I grind the hollow grind with new 60 grit belt, 150 mm contact wheel, 80 shore.

30 mn of work after

It's already thin

I chequered the back, 3 normalization, oil hardening.

After the quench, the sharpening file slide on the edge.

I cleaned the blade, and propan torch flash tempering. I did a gold tempering.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

sharptonn (04-28-2011)

-

04-28-2011, 08:00 AM #3Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

Between 0,23 and 0,21 mm thick after the 120 belt.

Between 0,16mm and 0,18 mm after the 240 grit

I countersinked the side of the blade, and clean it with a 500 grit belt. I'm between, 0,09 and 0,13 mm

I etched my logo

I cut stainless piece (304 or 316L i don't know), 1,6mm thick.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

sharptonn (04-28-2011)

-

04-28-2011, 08:01 AM #4Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

I put the BP washer in order to see where i need to point.

I drilled to 3,8mm, reamed to 4mm, and drilled the heel to 4mm

Some hole.

I draw vaguely the handle.

I check the position of the blade

I shorten the various pieces.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

sharptonn (04-28-2011)

-

04-28-2011, 08:02 AM #5Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

The spacer is in a scrap piece of T40 (ti grade 2). Drilled to 4mm and bevelled.

I grind the handle with a 60 belt, i put the spacer in place and pinned it with a brass pin. (+ epoxy)

I fold a bit the stainless handle.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

sharptonn (04-28-2011)

-

04-28-2011, 08:02 AM #6Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

Some black compound, and green compound on buffer, that is already able to shave hair on the harm.

My sharpening kit, Japanese stone 800, 1000-3000, chinese stone 8000 and 12000. A piece of jean straighten on a oak plate with red buffering compound, a paddle with leather and green compound and on the other side simply leather.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

sharptonn (04-28-2011)

-

04-28-2011, 08:03 AM #7Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

After sharpening, and 1 week of shaving, that is not bad at all. I'm almost to the level of my favorite straight razor. It's less hollow grind than i would have thought, the edge is "straight" i would have think it would be more flexible. The edge retention is not bad at all.

It's a 5/8 , 7 cm sharp, blade 14,5 cm , 6mm thick to the pivot, and on all the back. Highness closed 2,3 cm to the highest.

I'm satisfacted by the result.

I would have to keep a bit more material at the begin of the tang to a better hand take, and i would need to try to decrease the thickness at the pivot level, but i didn't find the solution to have something less thick and perfectly clean and perpendicular for the pivot (the screw are less tolerant than pins).

Thickness, 12mm to the pivot, 3,5 mm to the heel. 16 cm closed

Sorry for the poor quality of the picture, in my workshop i don't have a lot of light

-

The Following 6 Users Say Thank You to cardoso5fr For This Useful Post:

cpcohen1945 (04-30-2011), leadingedge (04-29-2011), lz6 (05-03-2011), Nervin (04-29-2011), ScottGoodman (05-01-2011), sharptonn (04-28-2011)

-

04-28-2011, 08:18 AM #8

Nice looking razor . How does it balance with the steel scales ?

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

04-28-2011, 08:25 AM #9Senior Member

- Join Date

- May 2009

- Posts

- 102

Thanked: 32

Thank you, the balance is not bad, the handle are quite heavy but the blade thickness give also some weight to the blade.

The begin of the tang would have been a bit larger in order to have a better stabilization between the finger (it roll a bit between wet finger), but the balance is ok. I shave me with that one from two week and i'm quite happy

Last edited by cardoso5fr; 04-28-2011 at 11:34 AM.

-

The Following User Says Thank You to cardoso5fr For This Useful Post:

onimaru55 (04-28-2011)

-

04-28-2011, 10:53 AM #10..mama I know we broke the rules...

- Join Date

- Feb 2010

- Location

- Toronto, Ontario, Canada

- Posts

- 2,895

- Blog Entries

- 8

Thanked: 993

That is a very sleek looking razor. Nice work for sure.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote