Results 11 to 20 of 33

Thread: A San Mai in progress

Threaded View

-

03-19-2013, 10:15 PM #1

A San Mai in progress

A San Mai in progress

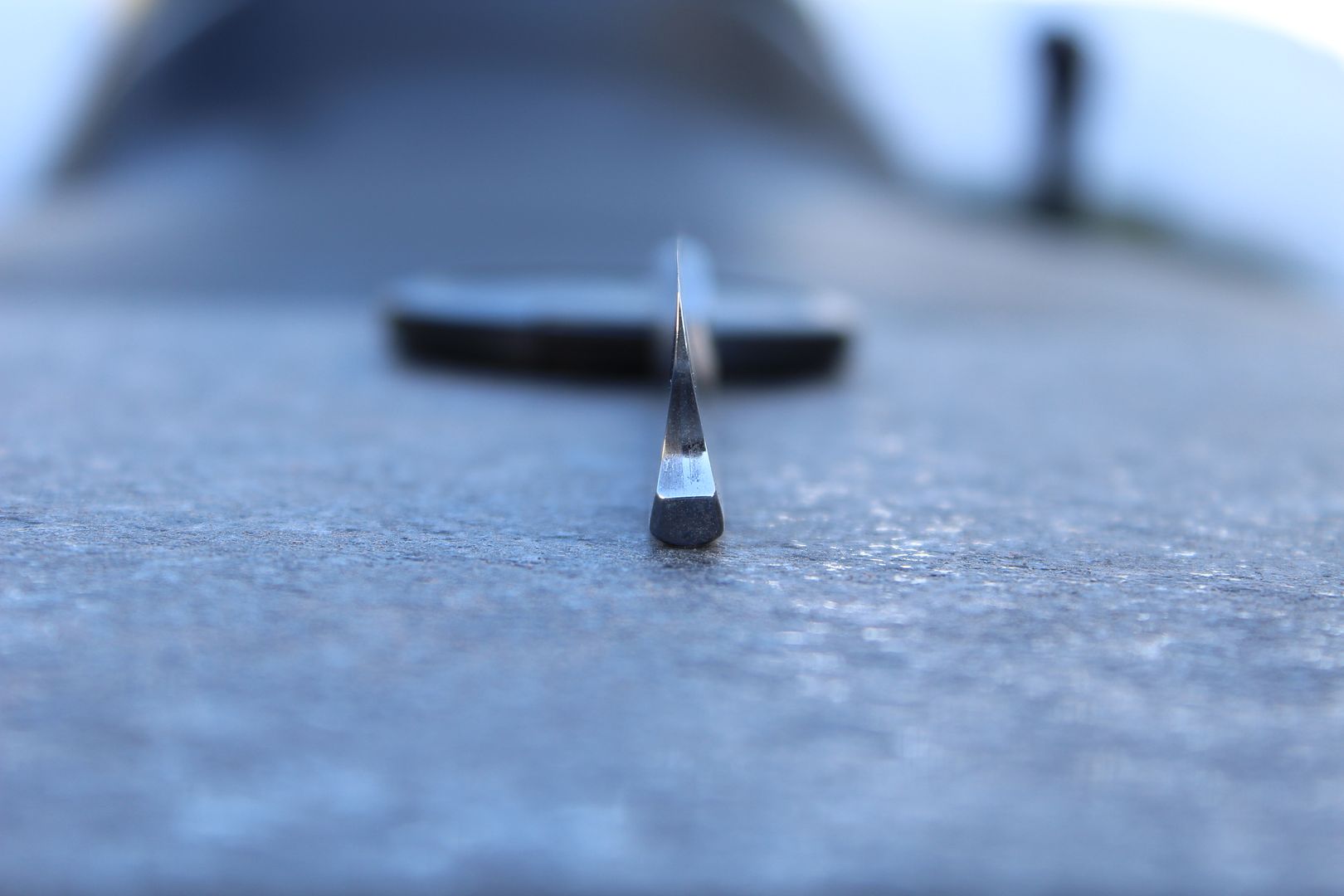

Hey guys, this a 7/8 (measured from the stone contact point on the spine, 8/8 high) near wedge

San Mai construction, comprised of an O1 core, with 88 layers of 1084 and 15N20 on either side. The last one I did, had a black etched core

this one I polished.

As you can see, it has a slight smile, and a barbers notch.

I now have to choose scales, likely going to go with horn. Stay tuned...

Thanks for looking, comments welcomed!

My friends call me Bear.

My friends call me Bear.

-

71Likes

71Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote