Results 1 to 10 of 33

Thread: A San Mai in progress

-

03-19-2013, 10:15 PM #1

A San Mai in progress

A San Mai in progress

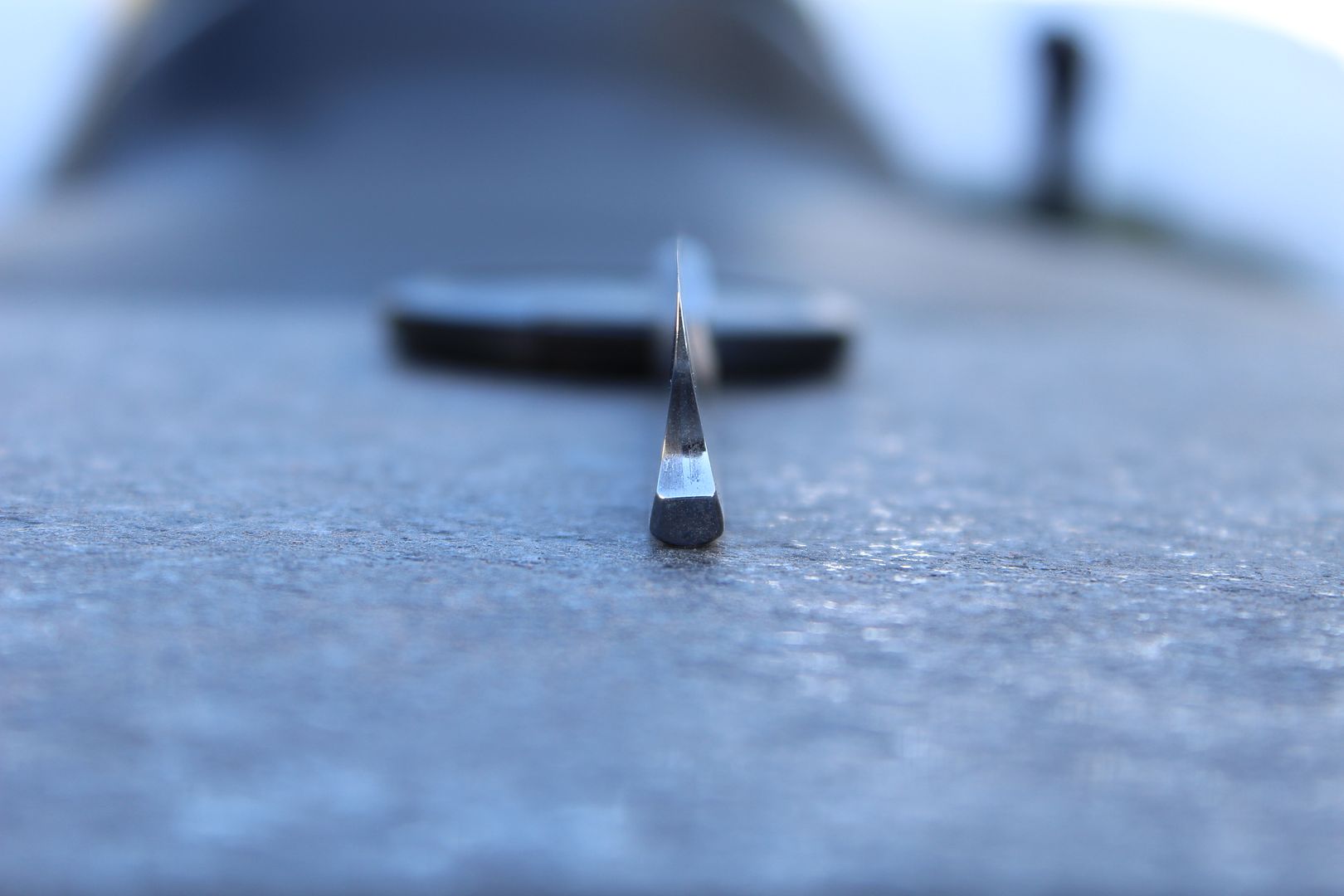

Hey guys, this a 7/8 (measured from the stone contact point on the spine, 8/8 high) near wedge

San Mai construction, comprised of an O1 core, with 88 layers of 1084 and 15N20 on either side. The last one I did, had a black etched core

this one I polished.

As you can see, it has a slight smile, and a barbers notch.

I now have to choose scales, likely going to go with horn. Stay tuned...

Thanks for looking, comments welcomed!

My friends call me Bear.

My friends call me Bear.

-

-

03-19-2013, 10:25 PM #2

-

03-19-2013, 10:32 PM #3I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Looking great Pierre

Stefan

-

03-19-2013, 10:34 PM #4Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

Thats beautiful, looking forward to seeing the finished result.

I think horn would be a nice choice.

Grant"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

03-19-2013, 10:41 PM #5

Looking great! I don't know what San Mai is, but that is one good looking razor. Good luck with the scales.

-

03-19-2013, 10:51 PM #6

San mai is done a lot in kitchen knives. A hard core is sandwiched between two softer pieces of steel and forge welded. Sometimes the core only goes part way to the spine. It was don to be able to make the core quite hard, and the softer sides would support the core.

In this one the O1 core goes from edge to spine, and the damascus/pattern welded steel on the sides, is made of a fully hardenable steel.My friends call me Bear.

-

03-19-2013, 11:29 PM #7

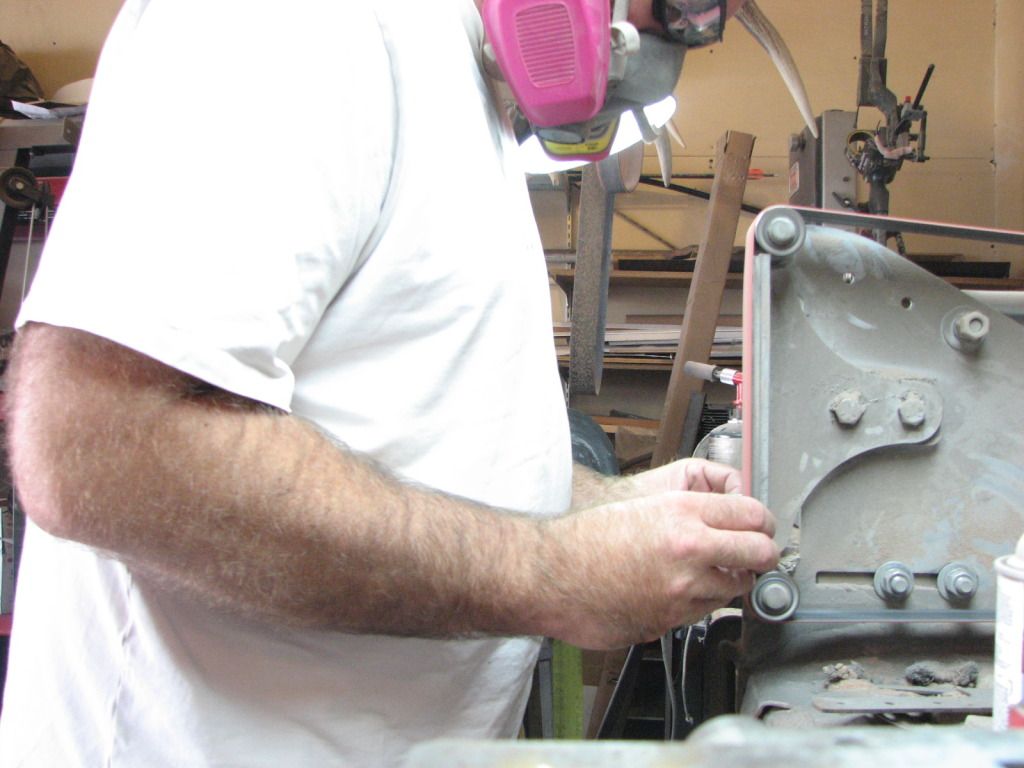

Here is the process...

First the steels are forged for the damascus pattern...

The billet is cleaned up... and the damascus sides are forged to the core...

My friends call me Bear.

My friends call me Bear.

-

-

03-19-2013, 11:29 PM #8

Then it is annealed to make it easier to work with...

After all that, the bar is cut in to manageable pieces...

Portioned...

And a light etch, to check core alignment...

and pattern density...

Then the profile is laid out, tang hole drilled, and hollow grinding begins...

My friends call me Bear.

My friends call me Bear.

-

The Following 10 Users Say Thank You to PierreR For This Useful Post:

Adam G. (03-19-2013), dfrazor (03-20-2013), engine46 (01-07-2016), gregg71 (01-07-2016), Lemur (03-19-2013), lz6 (03-19-2013), rkw216 (03-22-2013), ScottGoodman (03-21-2013), Speedster (03-20-2013), str8fencer (03-20-2013)

-

03-19-2013, 11:30 PM #9

Then the grinding is taken to about 80%, the blade is heat treated, and after the grinding is finished...

My friends call me Bear.

My friends call me Bear.

-

-

03-19-2013, 11:40 PM #10

Can't wait to see your finished straight. Thanks for sharing the process that blade is just beautiful to look at.

Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

71Likes

71Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote