Results 11 to 20 of 25

-

03-31-2014, 04:11 PM #11Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Had a productive Saturday. I put an edge on both the choppers and commenced to strength test them. I chopped through a few branches with zero visible edge wear and still able to shave hair.

Then I got the handle glued up.

Roughed them out on the belt grinder.

Here's the other one in canvas micarta.

Got the the handle pretty much finished and put it through the hanging rope test. No visible edge damage after, still able to shave.

The finished pair. The one on the left is the one in 5160 with a stabilized buckeye burl handle and a single mosaic pin. The right is 52100 in canvas micarta also with a single mosaic pin. They were honed with a DMT coarse, Norton 1k, Norton 4k and Shapton 8k pyramided.

Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

03-31-2014, 10:56 PM #12Bladesmith by Knight

- Join Date

- Jun 2007

- Location

- Murrumba Downs, Queensland, Australia.

- Posts

- 571

Thanked: 203

Loving your work. Especially good to see you test your blades for performance.

Surprising how many people do not.

Surprising how many people do not.

Keep 'em coming.

Adam

-

The Following User Says Thank You to Adam G. For This Useful Post:

PapaTony (04-01-2014)

-

04-01-2014, 02:36 PM #13Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

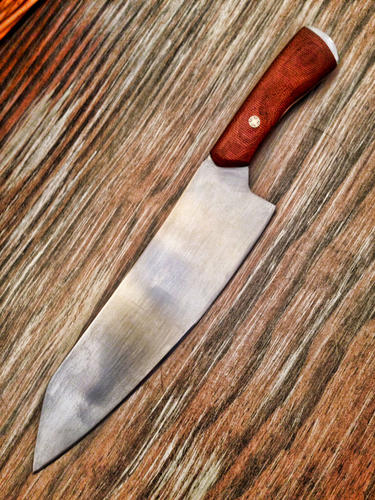

Thanks Adam. I guess it's easier to send out a sub-par blade than remake the whole thing! I cooked with the micarta one last night and it performed really well. I'm loving the handle design on these; I'll definitely do more like this. It's comfortable and functional.

A bit better finished pics:

Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

04-04-2014, 01:56 PM #14Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Well, I snapped the tail off the original Frenchy trying to straighten it. I made another one though, same design. This one 13/16 out of O1 in Osage Orange scales. I took it up to 600 grit on the KMG, then hand sanded to 1200.

The bevel is a little wide, but even.

Next to a Hart 7/8 for comparison:

I set the bevel on a DMT coarse then moved to Norton 1k then Norton 4k and Shapton 8k which I pyramided. From there, I finished on a JNat with slurry, diluting down as I went and then CrOx on balsa. Then, linen and leather. I got the heat treat dead perfect. The shave was buttery smooth. It even went through my thick beard ATG, which is a feat I've only pulled off with a Wonderedge and the Robert Williams SRP.Let me know if you need any help with shaving, honing, etc.

-

04-08-2014, 06:57 AM #15

Nice work man!

Can you please explain how exactly temper O1 steel? Temperature and etc.

-

The Following User Says Thank You to davorvfr For This Useful Post:

PapaTony (04-08-2014)

-

04-08-2014, 02:46 PM #16Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Thanks Davor!

I heat treat O1 as follows:

Normalize (stress relief): bring up to 1250 (F) slowly, cool to black

Hardening: bring up to 1475 (F) and hold for 10 mins, quench in a medium speed oil that's around 140 (F). When I quench, it's really an interrupted or marquench meaning I quench in oil, agitate rapidly, and pull out while the oil still smokes when the blade touches it. From there, you can either air cool or pop it in an oven for tempering at 425 (F).

Cryo: at this point, you can cryo your blade for added tensile strength (check out Tim Zowada's website for some info on this), but I've done non-cryoed blades that cut great too.

Temper: 2 hours at 425 (F) produces an HRC of a bit higher than 61, which is my preference for razors and an ideal hardness for O1.

Let me know if you need any help with shaving, honing, etc.

-

-

04-09-2014, 07:03 AM #17

-

The Following User Says Thank You to davorvfr For This Useful Post:

PapaTony (04-09-2014)

-

04-09-2014, 02:11 PM #18Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Well, if you get one thing right, better make sure it's the HT! With so thin a blade and so perfect an edge, if you mess it up you'll definitely find out, likely before you ever get an edge on it.

I've got a Hart Steel and it just wont take a good edge, no matter what I do. They're cryoed and salt bath HTed, but I still prefer the edge on the blades that have come out of my forge. Wouldn't mind getting a kiln though...Let me know if you need any help with shaving, honing, etc.

-

04-09-2014, 04:34 PM #19aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Salt baths are the cream of the crop for absolute temp control, one of our local HT masters uses it and if I hit the lottery I would use it too.

If you would like someone else to try an edge on your Hart, PM me & cover the shipping. I can tell you within a few minutes on the stones if the HT is blown.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

04-09-2014, 06:06 PM #20Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Thanks for the offer shooter. I don't think the HT was blown, it just has an ugly hone job on it right now. The shave is uncomfortable. I think I need to reset the bevel on the stupid thing, but just have better things to do right now. I took it to my Shapton 8k to try to get something out of it, then finished on a Jnat, crox, strop and it wasn't good. Then, I took it down to 4k and back through the same progression and it was still ugly. Really, it feels like someone set the bevel on this (already 1/4" thick blade) with like 5 layers of tape.

The razor I made above shaves great and I've taken several other from trash to nice-shaver. I think all that's left to do is butter knife this one and put my own edge on it.

Let me know if you need any help with shaving, honing, etc.

30Likes

30Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote