Results 1 to 10 of 25

-

03-24-2014, 04:50 PM #1Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45 What to do while tempering (a 7/8 Frenchy work in progress)

What to do while tempering (a 7/8 Frenchy work in progress)

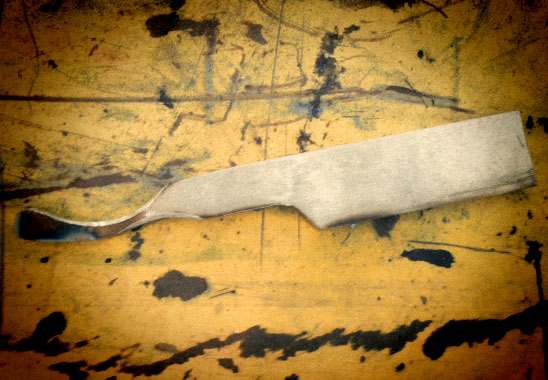

I got two 8" choppers rough ground and HT'ed and in the oven for tempering and needed something to do. Here are the choppers:

![Name: photo 2[1].jpg

Views: 392

Size: 28.0 KB](https://sharprazorpalace.com/attachments/forge/160781d1395679386-what-do-while-tempering-7-8-frenchy-work-progress-photo-2-1-.jpg)

Here's what I started:

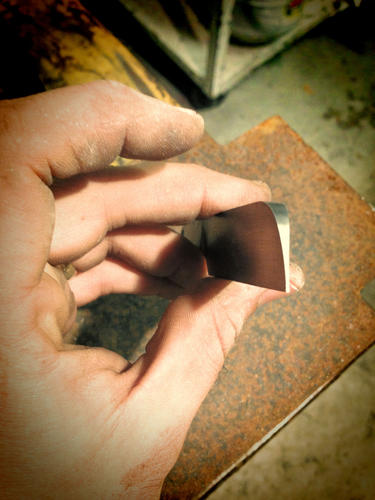

After talking to Bob and Charlie at the Texas meet, I wanted to make one really badly. I gouged this out of a chunk of 1/4" thick Starrett O1. Now it's rough ground. It still needs a bit of refining (and a pin hole) before HT, but that's the point of a WIP thread!

More to come later this week (and some chopper updates if y'all want 'em!).Let me know if you need any help with shaving, honing, etc.

-

03-25-2014, 03:13 AM #2

Just be careful with that spike point.

I did this from the end of a square point this morning and my three year old said, "Daddy, there's blood everywhere!"

-

03-25-2014, 09:08 AM #3

I like the shape of those knives. look forward to seeing them (and the razor) completed.

-

The Following User Says Thank You to EisenFaust For This Useful Post:

PapaTony (03-25-2014)

-

03-25-2014, 01:55 PM #4Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Yeah, that spike'll get ya! I may dull it a bit, but it's far from finished.

Glad you like the shape of the knives. It's a slight swayback with a drop point, which makes it easy to roll the blade while chopping. Each one will have a single mosaic pin (I drilled the hole before HT, don't worry) and I'm thinking something burly for the handle material.Let me know if you need any help with shaving, honing, etc.

-

03-26-2014, 02:07 AM #5Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

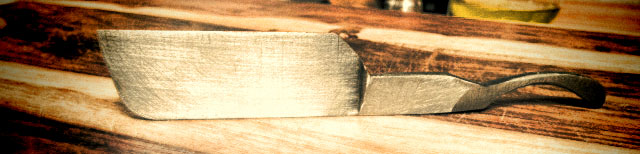

Finished rough grinding to 220. Then did the initial HT. Man, I love O1! Couldn't be simpler!

I know the pivot hole looks big and that's because it is! Pixel said that he could only abide big pivots on custom razors and guess what this is. I got some pivots similar to Hart Steel's.

Here it is with some scale on it. She looks pretty good in matte black, huh?

Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

03-26-2014, 04:11 PM #6Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Razor from the front. Maybe 1/4 hollow.

Chopper from front. You can see the distal taper pretty well.

Here's the business side of it. It's got a nice roll to it.

Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

03-26-2014, 04:18 PM #7Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Meant to say that the choppers finished tempering (2 times for 2 hours at 425) and that I got the scale off one of them.

They're both going to have a single mosaic pin when they're done.Let me know if you need any help with shaving, honing, etc.

-

03-26-2014, 07:22 PM #8aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

You seem to have a natural ability working steel, is this your first time with knives/razors?

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

PapaTony (03-26-2014)

-

03-26-2014, 07:46 PM #9

nice job, makes me jealous. making knives/razors has always been something i've dreamed of doing.

-

The Following User Says Thank You to tintin For This Useful Post:

PapaTony (03-26-2014)

-

03-26-2014, 09:26 PM #10Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

Thanks! This is my second attempt at a razor. My first one ran into a couple of problems. Although I do think I could get it shaving, you just gotta know when to walk away sometimes.

Knives, on the other hand, I am not new to. I used to be a chef (and still cook a lot), so I had to develop a lot of knife skills, but had never made one. I've always loved working with my hands and was pretty decent at woodworking, but had never done anything with steel apart from some welding and fixing dents in cars. I really started wanting to make knives and razors when I found this forum. I saved up for a belt grinder and got a lot of other tools from craigslist and started making them. While you can learn a ton online, it's no substitute for real practice.

tintin: come on down to Texas. Us and Shooter can have a mini hammer in!

Let me know if you need any help with shaving, honing, etc.

30Likes

30Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote