Results 1 to 10 of 18

Thread: My first 3 Razors WIP

-

05-01-2014, 08:41 AM #1Junior Member

- Join Date

- Apr 2013

- Location

- Stockholm, Swedcen

- Posts

- 15

Thanked: 0 My first 3 Razors WIP

My first 3 Razors WIP

Hello,

I have made some progress on my first three razors, one will be my interpretation of a kamisori or a fixed blade / one piece razor. Please keep in mind that this is the first time I have ever ground a hollow grind, apart from one prototype that I made in aluminium. I'd like to show you some pics so far, since I do have a few questions

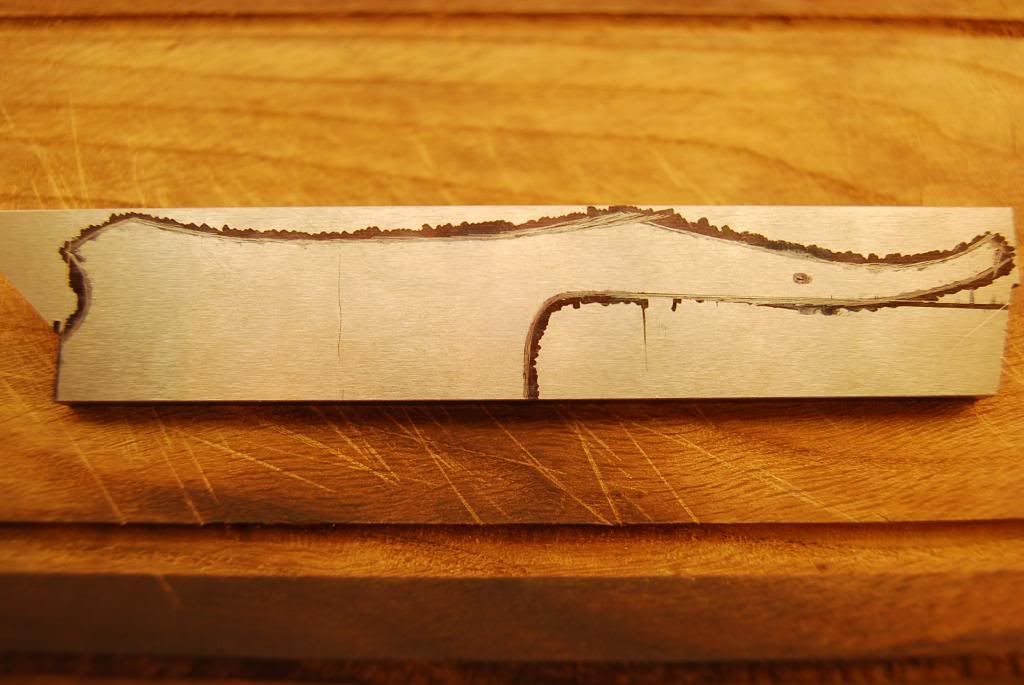

This is the aluminium prototype that I made, please note that I did zero finishing work on it and everything is very rough and crude!

The holes were mainly for decoration but also a way to lighten the blade and get the balance I wanted.

Here are the razors so far, they are made from 6 mm (0.236 inches) SS 2140.

I might change some details on the razors once I have cut them out, so the current blade profile is just to give me an initial shape, If I don't like something I will change it as I go.

I plan to grind the hollow as deep as possible on the kamisori, and I think I might have to taper the tang to get a decent balance.. I'm wondering how far I should take the taper? Past the plunges? And how much can I grind before I send it out to HT? Currently there is about 1,5 mm (1/16 ") at the edge, but as you can see in the third picture I could work the hollow further up by grinding behind the edge.

I have also been trying to find out how you go about tapering the tang on a "normal" straight razor, how far do you taper? Past the plunges on them as well? It's not the tapering process itself that I have questions about, I already know how to taper the tang on a fixed blade

Kind regards

Max

-

05-01-2014, 09:42 AM #2

Looking good I like your prototype pity it's only Ali good idea but

Sorry I can't help with the rest although I have read several times that about an 1/8" is the thinnest you want to go on the edge before the heat treating to avoid warping with O1 not sure on the SS2140Saved,

to shave another day.

-

05-04-2014, 07:33 AM #3

The tape should run past the shoulders, 1/4" into the blade.

That will be necessary for maintaining a good contact between the spine and the hone.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

05-04-2014, 08:37 AM #4Junior Member

- Join Date

- Apr 2013

- Location

- Stockholm, Swedcen

- Posts

- 15

Thanked: 0

Hm...Would not taking the taper past the pivot interfere with the washers? I will drill the pivot hole before doing the taper, but in my mind, placing washers on a tapered surface would cause problems? My old razor does not have any washers but I can see that the taper runs about 1/4" past the plunges....I am most likely wrong, but since I have not done a razor before I felt that I should ask before I start tapering?

Thank you for your time!

Kind regards

Max

-

05-04-2014, 09:20 AM #5

Take Bruno's advice - otherwise you'll regret it when it comes to honing. The shoulders on your mock up will hit the side of the hone.

regarding the washers, remember that the scales will also flex meaning that the washers will be flush against both tang and inside scale.Last edited by UKRob; 05-04-2014 at 09:23 AM.

-

05-29-2014, 02:25 PM #6Junior Member

- Join Date

- Apr 2013

- Location

- Stockholm, Swedcen

- Posts

- 15

Thanked: 0

-

05-29-2014, 08:16 PM #7

No, the tang should be tapered past the shoulder and this will not interfere with the washers.

The end spacer should also be wedge shaped so that the scales are open.when you pin the razor, you have to 'wrap' the scales around the razor. That way you also create mote space for the shoulders. You don't want the scales to be in parallel.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

05-30-2014, 06:06 AM #8Junior Member

- Join Date

- Apr 2013

- Location

- Stockholm, Swedcen

- Posts

- 15

Thanked: 0

I did take the taper past the plunges, and I did know that the backspacer should be tapered

I had no intention of ignoring your advice, I was simply curious, thank you all foryour advice!

I had no intention of ignoring your advice, I was simply curious, thank you all foryour advice!

Last edited by Sompla; 05-30-2014 at 06:09 AM.

-

06-03-2014, 12:51 PM #9Junior Member

- Join Date

- Apr 2013

- Location

- Stockholm, Swedcen

- Posts

- 15

Thanked: 0

-

06-03-2014, 03:13 PM #10Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I have a question about jimps, not specifically these ones but just jimps in general. I presume they are cut with a file that has the teeth in alignment. When the razor is finish the jumps are nice and polished through out. Looking at the after heat treat pictures it leaves me wondering if those same files are used to clean out and polish the jimps to leave them pristine or is there another process for that.

It's not what you know, it's who you take fishing!

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote