Results 1 to 10 of 86

-

06-04-2014, 04:03 AM #1Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59 First Straight Razor Build (A learning Process)

First Straight Razor Build (A learning Process)

I would like to build a straight razor myself and post the progress here. The point of posting my progress is two-fold. First, is that it may help others who are trying to do the same thing. Second, is that the other members here may see me making a mistake and point me in the right direction before I go too far down the rabbit hole (been there, done that, bad idea, etc...).

I have made many hundreds of knives in the past but this is my first attempt at a straight razor and I realize that a much of what I know will have to be un-learned. Razors look to have a lot of differences between them and hunting/kitchen knives. Grind geometry, edge angle, desirable steel qualities all look to be different than what I am used to.

Please let me know if this is the correct place for such a thread and I will proceed accordingly.

Thanks!

-

06-04-2014, 04:54 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Looks like the right place to me :<0) Welcome and good luck. There are lots of threads to read on the processes used and my eyes are still bleeding from reading myself.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

06-04-2014, 05:17 AM #3Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Thanks, I have been reading posts on here quite a bit lately as well and am about ready to start the process. However I wanted to bounce some ideas off of the members here before ordering parts.

The first thought I had was to choose the steel. Below is a list of the steels I am considering and why I thought that they may work well based on my knowledge and experience with them. I would prefer to use use the stock removal method over forging unless there is a significant advantage to forging (My current forge is only about one third finished). Any thoughts or opinions would be appreciated.

1070/1085 – Basic Good 'ole Fashioned High Carbon Steel. The last two digits indicate the carbon percentage (Example: 1085 has .85% carbon). It is inexpensive, easy to work and sharpen. It should get a fine edge as well as heat treat easily with oil.

1095 – Basically the same as above but with more carbon. It is easier to find in flat stock, but is harder to heat treat (needs a faster cooling oil or water). I may send it out to be professionally heat treated if I go this way.

5160 – Similar to 1095 but more alloys to make it a “spring steel”. The appealing thing with this is that there is an abundance of it around here in the form of old car springs. I've forged quite a few hunting knives from leaf and coil springs. In the end, I thought that it was too “soft” for a hunting knife, but now that I look at it in the light of straight razors, it may be a good option.

O1 – A high carbon Tool Steel. Looks to be popular as a razor material and is easy to find around here. I made quite a few hunting knives out of this and it was a pleasure to work with. It is significantly more expensive than 1095 and I'm not sure if it would make a noticeable difference over 1095.

52100 – High carbon “bearing steel”. This is known for getting a very fine edge. I made one hunting knife out of this and I was amazed how easy it to get it “scary sharp”. It's hard to find around here in a variety of sizes. It's often sold as forging stock and is not always easy to find in smaller flat bar. It is also significantly more expensive than 1095.

ATS-34 – My favorite “all-round” stainless steel. It is relatively inexpensive and easy to find in small flat stock. I have read of some people saying that it is hard to hone, but after grinding on steels such as D2 or CPM S-30V, working with ATS-34 is like cutting butter.

-

06-04-2014, 04:10 PM #4Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I've used O1 and like the results. I just made some knives from 1095, and I'm sure that would work well also. You are in luck, living in eastern Washington. You don't live too far from Mike Blue, who knows more about steel that just about anyone out there. He is on this forum, and I'd strongly suggest PM-ing him and trying to set up a visit. A great guy, and an amazing resource. He will also doing custom heat treating in molton salt. Good luck on your razor journey.

-

The Following User Says Thank You to skipnord For This Useful Post:

DVW (06-05-2014)

-

06-05-2014, 03:06 AM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

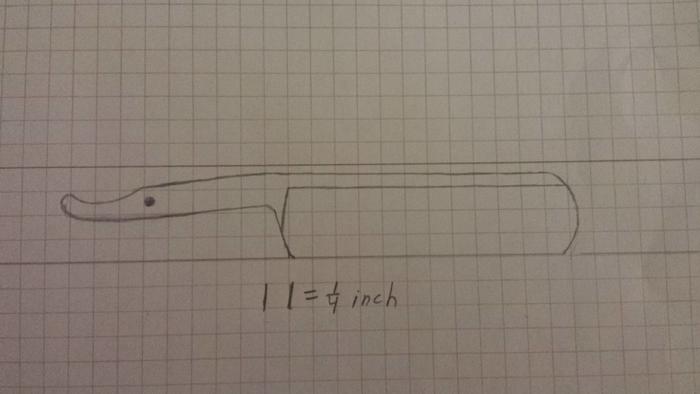

I sent him a PM. Thanks for the pointer. While I debate the type of steel, I drew up a sketch of the blade. The goal is to have something that is fairly basic, relatively easy to make, looks good and easy to use for a beginner (me). What I came up with was a blade about 3 inches long, by about 7/8 inches wide and 1/8 inch thick at the spine. Thoughts??

-

06-05-2014, 04:53 AM #6Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

1/8 is too thin. There is a formula around here for thickness to width. As I recall it is somewhere around 15 to 19 degrees angle on the bevel. You can do the math or search out the formula. ( In case I don't find it for you ) From my reading and being in the same boat as you I started with O1. I have some RSO's but have yet to finish enough to start heat treating. Which I may also have done by pro the first time. To anxious to have one of my own made and use it to mess up 6 blades learning to heat treat. Mike Blue is THE guy to listen too when it comes to steel. If I lived where you do I would probably be camped on his shop doorstep :<0)

Okay I found a place to start. I got 1/4 " stock and took it down to 3/16 for a 5/8 blade. Shooting from the hip is my style, checking for accuracy after.

http://straightrazorpalace.com/advan...pers-tape.htmlLast edited by 10Pups; 06-05-2014 at 04:59 AM. Reason: edit angle:<0)

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

06-05-2014, 05:09 AM #7

Thickness of the spine should be 1/3 to 1/4 of the width. Don't don below 1/4 because you'll end up with something that looks like a razor but won't work.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-05-2014, 05:11 AM #8

EDIT: Copied from an earlier post of mine, in a similar thread about making a razor.

You want to taper the handle as well. Under no circumstances should you have a tang /handle that is

exactly as wide as the spine.

Once you start honing, the spine will get thinner. Not by a lot, but still. When this happens, you still want the blade to be perfectly flat on the hone. For this to happen, the tang / handle should never touch the hone, or you will get a sloping transition where the spine (and thus the edge) will always 'wobble'.

With knives you often see a small notch between the edge and the bolsters. this is for the same reasons: to make sure that the beginning of the edge will always touch the stone properly.

Also the following things:

- you don't want the tang to end in perfectly sharp corners, because you will scratch up a lot of things in the bathroom. the only sharp thing should be the edge

- get used to measuring things in empirical units. As much as I live in a metric country anduse the metric system for everything, the razor world operates in units of 1/16 inch for measuring the width and thickness of a razor. For lengths it's inches. Everything will go a lot smoother if you measure width in 1/8 or 1/16.

- carbon steel is perfectly fine for a razor. No need to consider it 'making do'. A razor is not subject to stress, fatigue, etc. The only thing that matters is the ability to take an edge and be relatively easy to hone. high carbon tool steel is a perfect steel for a razor. If anything, the challenge is to achieve the same level of edge quality with stainless, not the other way around.

- for the thickness you want to aim between 1/4 to 1/3 for the thickness vs width ratio. do not go smaller because your razors will be difficult to hold and lose its edge relatively quickly. In your case for 22 mm of width (~7/8") you want a stock thickness of close to 1/4"

- Leave the edge 1/16 before heat treatment, and grind away the rest of the hollow after quench and tempering.

- You need to grind the hollow so close that during honing, the bevels are uniform, and very thin. Ideally, the bevels should be a very thin, almost invisible line. A wide and uneven bevel is the sign of sloppy workmanship, and often indicates that only minimal post HT ginding was done.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

-

06-05-2014, 05:13 AM #9

And stay away from 52100 if you don't HAVE to use it for razors. Yes, it's good steel, and can stand a lot of abuse. But for a straight razor, those qualities are not needed, and will make it a lot harder to hollow grind the blade.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

DVW (06-05-2014)

-

06-05-2014, 05:14 AM #10Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I wondered about this, but don't understand the relationship. The below sketch is not to scale, but what does spine thickness have to do with edge angle?

71Likes

71Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote