Results 31 to 40 of 77

-

02-08-2015, 09:32 PM #31"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

-

02-10-2015, 12:58 PM #32

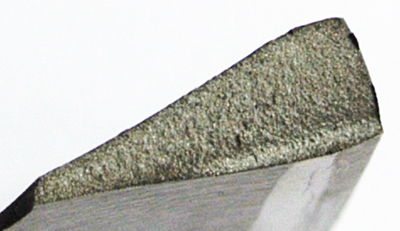

I made some pictures today. I hope to see the details.

First attempt

edge 0.5 mm

normalizing: 805C, 3 times

soaking: 805C, 15 min.

quenching oil: 80C, 5-10 sec

tempering: after cooling to room temperature, 200 C, 2x1h (between cooling to room temperature)

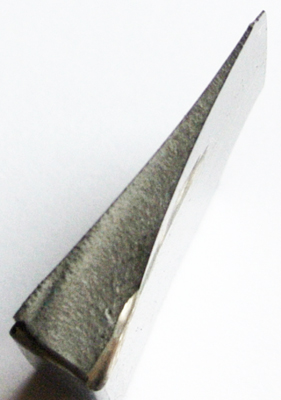

Second attempt

edge 1 mm

normalizing: 790C, 3 times

soaking: 790C 15 min.

quenching oil: 70C, 30 sec.

tempering: after cool enough to touch, 220 C, 2x1h (between cooling to room temperature)

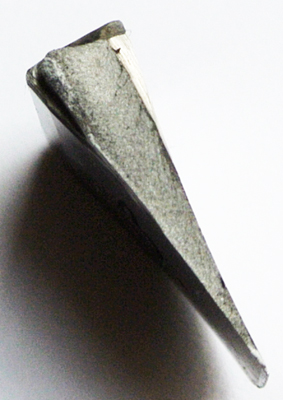

Third attempt (a second time HT)

edge 0.5 mm

normalizing: 800C, 3 times

soaking: 800C, 15 min.

quenching oil: 50C, 10-15 sec.

tempering: after cool enough to touch, 200-205 C, 2x1h (between cooling to room temperature)

Heat treated razor by a hungarian knife maker

His oven the same as me. The staining caused by water

Professional heat treating

I can see that my razors have too large particles. Do you have any idea how can I improve?Last edited by gregg71; 02-10-2015 at 01:07 PM.

gregg

-

The Following User Says Thank You to gregg71 For This Useful Post:

ScottGoodman (02-10-2015)

-

02-10-2015, 02:29 PM #33aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

These are all the same steels right? Is your normalization process just letting air cool? Are you quenching more than once?

For us on the silly English system, so I have to do the conversions to F:

#1

805C=1481F Normalizing/Soak

200C=392F Tempering

80C=176F quenchant oil

#2

790C=1454F Normalizing/Soak

220C=428F Tempering

70C=158F quenchant oil

#3

800C=1472F Normalizing/soak

200-205C=392-401F Tempering

50C=122F quenchant oil

I am truly interested in hearing from the experts on your findings too as to me the temps are relatively close for the three experiments and I would expect to see about the same results.

I have not done tests like yours back to back to document like you have. Very informative & great pics, thank you for sharing!Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

gregg71 (02-10-2015)

-

02-10-2015, 03:56 PM #34

We use centigrade in England

The grain certainly looks finer in the last two pictures. I basically follow uddeholme's instructions for their O1 which can be seen here http://www.uddeholm.com/files/PB_Udd...ne_english.pdf .They recommend 650c for stress relieving and I notice you're going much hotter.

You are tempering much cooler than me but I don't think this will effect the grain, though I'm not 100% on that. What hardness are you trying to achieve? I have found when I temper up in the 61rc region the edge can be a bit chippy. I aim for 59rc with O1.

Other than that your process sounds fine to me.Last edited by mikew; 02-10-2015 at 04:00 PM.

-

The Following User Says Thank You to mikew For This Useful Post:

gregg71 (02-10-2015)

-

02-10-2015, 04:36 PM #35Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

I'm not the expert that Mike is, but I have produced a bunch of great edges so please take this for what it's worth. My setup is just a forge with a pyrometer. I can play with the valves and control temperature pretty well. I quench in a medium oil I got from Mcmaster Carr which I keep around room temperature (85 F usually, I'll heat up a piece of steel and drop it in if it's cold outside).

I've tried a lot of different HT methods, but found that Kevin Cashen's worked the best for me. http://www.cashenblades.com/steel/o1.html

To boil it down to what it means for you, here's what I'm seeing:

1. I think you're normalizing too low (1500 F instead of 1600 F).

2. I think you should stress relieve at 1250 F and ramp to 1500 F before quenching.

3. I think your oil is too hot. From what I understand, o1 doesn't want a super fast quench. Many people recommend Park's AAA quench oil, which is a slower oil than Park's 50. Not sure how it compares to what you're using. If we look back at Mike's previous comments, the hotter the oil, the faster the quench.

4. I think you should temper a bit hotter. Perhaps this is a personal preference, but I like my blades between 60 and 61 HRC; I just think that more than that is a pain to hone and feels too rigid on my face. This shouldn't really affect grain size, but should play into the edge you end up getting out of it.

Hate to throw something else into this age-old debate, but have you done any cryo treatment on these blades. I've heard differing opinions on O1 needing cryo, but Tim Zowada cryos his blades and his edges are legendary. Of course, Hart cryos theirs too and I'm not very impressed with them, but that's a whole different can of worms.Let me know if you need any help with shaving, honing, etc.

-

The Following User Says Thank You to PapaTony For This Useful Post:

gregg71 (02-10-2015)

-

02-10-2015, 04:42 PM #36

Is there any need to normalise if you're not forging? I suppose that comes down to whether your steel is of a known quality?

Last edited by mikew; 02-10-2015 at 04:51 PM.

-

The Following User Says Thank You to mikew For This Useful Post:

gregg71 (02-10-2015)

-

02-10-2015, 04:56 PM #37"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I agree. Ahem, some of us colonials can speak Centigrade at need, LOL. Good reference Mike! At some point the steel bar was above the coarsening temperature and that's where grain growth is going to occur. The austenitizing temperature use here is less than that as long as we have confidence in the temperature control (measurement of error in temp accuracy in the oven). Either the grain growth occurred before you got the steel or somewhere in the working process.

Tempering temperatures are where Uddeholm recommend for Rc 59ish, maybe 220C. Tempering should not affect grain to any degree.

You might try thermal cycling with an oil quench instead of normalizing. You only need to quench to black (400C), not to room temperature and the grain structure will be smaller with each cycle. I will do three cycles routinely. Warm oil would be fine. I suspect with your normalizing process that the grain was much larger than you see in these broken sections.

A second variable I would attempt to change given all that has been reported here is to limit the austenitizing soak time to five minutes. O-1 is a simple steel but it does have a minor chromium content and chromium is aggressive in carbide formation. My shop soak times are five minutes.

Thanks for the most excellent pictures and good notes on your times and temperatures.

A lot of good recipes are coming your way and everyone here has their favorite. It is because it works for each of us in our own shops. Somewhere in all these suggestions is the right combination for Your shop and experimentation will be how you find that sweet spot. Keep up the good work!

-

The Following User Says Thank You to Mike Blue For This Useful Post:

ScottGoodman (02-10-2015)

-

02-10-2015, 05:00 PM #38"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

In this case, clearly yes. The steel mills produce bars. They don't necessarily control the temperatures to do so. There are several of us who have been fooled by materials we purchased from mills in quantity. It always requires test batches to make sure it performs the same as we expect.

Over time, the experienced smiths seem to have developed a cynical skin about this. Sometimes they send you something that is "close enough" but not what you really wanted. Sometimes the yard monkeys are color blind and send you the wrong color coded material.

-

02-10-2015, 05:11 PM #39"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Papa, the subject of cryotreatment is interesting.

I don't think this problem will require it. It adds a set of variables that will only distract from the set of tools Gregg has to work with now. I don't believe it will change the grain structure in a good way since most of the work there is done before the final quench.

I have done it, and don't believe it to be useful or economically practical IF the steel is heat treated correctly AND is a low alloy steel like O1. High alloy steels (stain resistant etc.) can be improved after quenching. YMMV.

Update: I read the Uddeholm link that Mikew provided. It contains cold treatment information my old sheets do not. They include a data line labelled retained austenite, and that is the structure than cold treatments attempt to correct. That Uddeholm includes it is enough for me to acknowledge I don't know everything especially when trying to keep up to date on so many things at once. Uddeholm suggests such treatment for dimensional stability and structural components. I don't know how that will translate to razors but eventually one of us will figure it out.

Caveat: To this date, none of the O1 razors I've heat treated have returned for problems, or I have not been made aware of feedback I would like to have.Last edited by Mike Blue; 02-10-2015 at 05:53 PM.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

gregg71 (02-10-2015)

-

02-10-2015, 07:30 PM #40Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

I appreciate your input as always Mike

I'd like to highlight some of the things you said that stand out to me.

1. Quality (or state) of the steel is questionable. If he's just doing stock removal, the grain size wouldn't be explained.

2. Thermal cycling. Why didn't any of us think of that? I've done this with different steels, but not O1. This could be great!Let me know if you need any help with shaving, honing, etc.

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote