Results 71 to 77 of 77

-

02-19-2015, 07:15 PM #71

Sorry guys, I was stupid. I strongly trusted in screen of the oven. This is a small oven with specialities like powerlessness. I have done some test, you can see below the result.

A corrected my previous values.

First attempt

edge 0.5 mm

normalizing: 805(905-950)C, 3 times

soaking: 805(905-950)C, 15 min.

quenching oil: 80C, 5-10 sec

tempering: after cooling to room temperature, 200 C, 2x1h (between cooling to room temperature)

Second attempt

edge 1 mm

normalizing: 790(890-940)C, 3 times

soaking: 790(890-940)C 15 min.

quenching oil: 70C, 30 sec.

tempering: after cool enough to touch, 220 C, 2x1h (between cooling to room temperature)

Third attempt (a second time HT)

edge 0.5 mm

normalizing: 800(900-950)C, 3 times

soaking: 800(900-950)C, 15 min.

quenching oil: 50C, 10-15 sec.

tempering: after cool enough to touch, 200-205 C, 2x1h (between cooling to room temperature)

Heat treated razor by a hungarian knife maker

His oven the same as me. The staining caused by water

Professional heat treating

....

Seventh attempt

normalizing: none.

soaking: ~805C, 15 min.

quenching oil: 50C, 10 sec.

tempering: none

I learned a lot from this. Thank you everyone for your help!

Last edited by gregg71; 02-19-2015 at 07:19 PM.

gregg

-

The Following User Says Thank You to gregg71 For This Useful Post:

ScottGoodman (02-25-2015)

-

02-24-2015, 01:27 AM #72

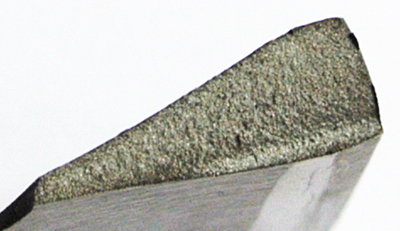

There you go! That looks like a fine grain structure!

My friends call me Bear.

-

The Following User Says Thank You to PierreR For This Useful Post:

gregg71 (02-24-2015)

-

02-24-2015, 08:07 AM #73

Yes, it seems. I am happy with it. I will change my thermocouple and make a complete HT. I hope...

gregg

gregg

-

02-24-2015, 10:24 AM #74

I wish I were having your troubles right now Gregg. I will one day attempt my own heat treating and when I do, I will remember some of these lessons. I have learned so much from your adventure and happy things worked out so well for you.

Thak you for your patience and determination!

-

The Following User Says Thank You to Gomerpile For This Useful Post:

gregg71 (02-24-2015)

-

02-25-2015, 06:02 PM #75Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

So you were accidentally austenizing at a temp 100C higher than the correct one? Well,that would certainly explain the beach sand sized grain!!!!! That last one looks pretty much spot on.

-

The Following User Says Thank You to JDM61 For This Useful Post:

gregg71 (02-25-2015)

-

02-25-2015, 06:05 PM #76

-

02-25-2015, 06:16 PM #77Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

Mr.Blue and some others could speak to this better than I, but the info that I have always been given is that the grain size blow up starts at temps above 1600F or around 871C for the kind of carbon/tool steel that we are discussing unless you have a steel with enough vanadium in it to delay that growth a bit and even then, it will still not be ideal. When guys over here do an initial "normalizing"cycle on spheroidized 52100 to break up the carbides and get stuff in solution, the do it at around 1650F or 898C. The DO get grain growth, but they count on the subsequent lower temperature thermal/normalizing cycles to take care of that. Sounds like you were growing grain at almost eve step of the process.

-

The Following User Says Thank You to JDM61 For This Useful Post:

gregg71 (02-25-2015)

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote