Results 1 to 10 of 45

Thread: Hot & Shiny WIP

Hybrid View

-

05-30-2015, 02:20 AM #1

My "original" design is a poor copy Mike Blue's forge.

It has turned out to be a popular design, 3 of my friends form Shreveport and East Texas measured my forge at the hammer-in the time before last. When I went out there last time they had made 3 more copies.

They have improved the design. Dan Graves,(smart talented knife maker) forge runs hot enough to make damascus, he made some ball bearing damascus when I was there using the little forge.

There are no new ideas

That is a beautiful forge you are making I admire it.

Charlie

Last edited by spazola; 05-30-2015 at 05:07 AM.

-

The Following User Says Thank You to spazola For This Useful Post:

Substance (06-01-2015)

-

05-30-2015, 08:45 AM #2Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

Nice little piece of gear!! There was and perhaps still is a bit of a misconception that you have to have a blower in order to get hot enough to forge weld. Some very clever and talented folks have come up with very efficient burner and forge designs without using forced air. I have done all of my forge welding in my original style Chile Forge Habanero model and I am told that the newer models with the modified T-Rex style burners are even better. I typically work with stacks that start off at 3 inches tall, by 1.5 wide by 6 long and have no problems.

-

06-01-2015, 11:21 AM #3

Thanks Charlie there is one question if you don't mind though, and that is I see that yours and the couple of others all have a fully welded in burner,

Does it have a nozzle tip also or another arrangement as mine blows out with no nozzle at 10psi and the tip is glowing after only a few minutes.

This might change when fully insulated and installed but I does have me concerned.

Regards DionSaved,

to shave another day.

-

06-01-2015, 02:02 PM #4

No nozzle tip but a little bit of a change in the diameter and surface as it goes through the side wall of insulation. It is just a piece of black pipe. I run mine at tank pressure no regulator, some of the other guys are using regulators I do not know what they are doing pressure wise.

It is just a piece of black pipe, air slots, mig tip letting propane in on one end, and welded to the other.

I always thought if I made another I would not weld the pipe on, but after seeing how well Dan's forge works I am not sure. I am beginning to think is 6 of one or a half dozen of the other.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

Substance (06-01-2015)

-

06-01-2015, 04:11 PM #5

-

06-01-2015, 04:38 PM #6

-

The Following User Says Thank You to spazola For This Useful Post:

Substance (06-01-2015)

-

06-01-2015, 04:55 PM #7

In Belgium and Germany, it seems common to use propane or butane canisters to make a forge. They cut off both ends, mount it horizontally, coat it like above, and shove a burner in the middle. They do this because those canisters are very strong, and cheap. I have seen pics of Achim making wootz by setting one of those things vertically, place the crucible in the middle, and put a tile on top of the opening.

Most smiths I know here work this way. People in the arts and crafts business tend to use regular coal. So far I am the only bladesmith I know here in this area who uses charcoal.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-07-2015, 09:05 AM #8

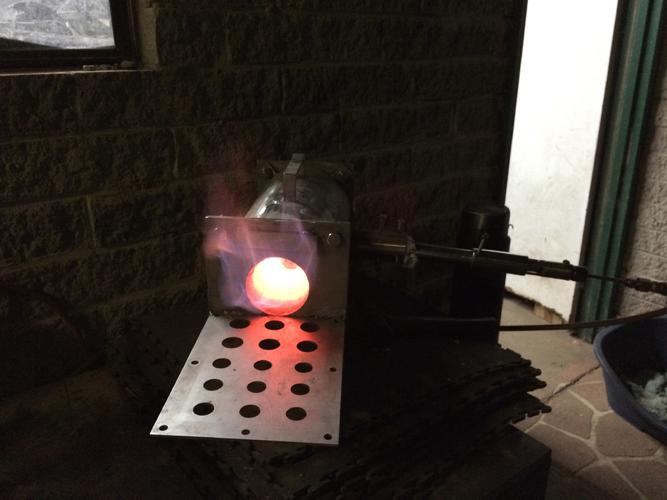

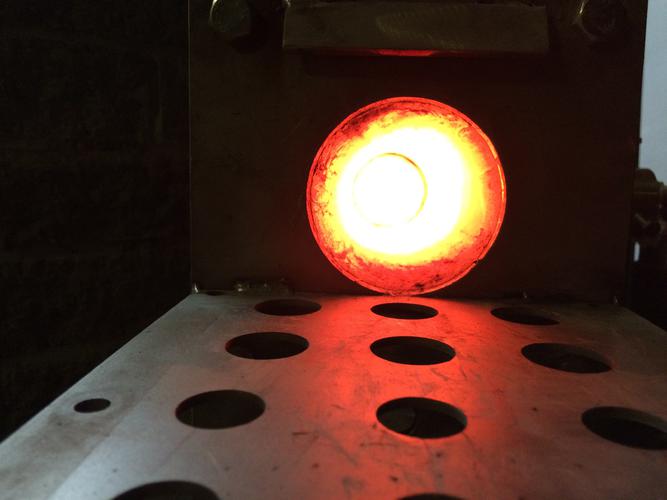

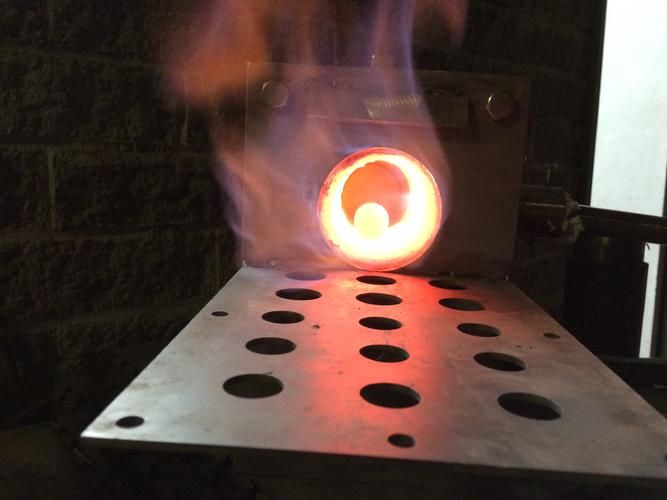

All Fired up

1st was a cure run

Then heated to critical (non magnetic) a couple of punches which are now in vermiculite annealing so I can try make a makers mark stamps

Last edited by Substance; 06-07-2015 at 10:41 AM.

Saved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

sharptonn (06-10-2015)

-

06-08-2015, 09:07 AM #9

Had a play with a piece of 1075 1/4"X1"x4" and forged this

Saved,

Saved,

to shave another day.

-

06-10-2015, 01:41 AM #10Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

You see that over here too tanks./canisters. You also see people using large diameter well casing pipe for vertical forges. For the big sword heat treating forges like the ones that Don Fogg built, they use oil drums. As for charcoal, you are kind of unique for a western smith. I think that the neb-tribal guys like Tai Goo and Tim Lively and folks like Murray Carter who do the traditional Japanese smithing use it, but most use either propane or coal/coke. I have seen some guys use waste oil or natural gas too. We may have an advantage in the US in that gear for small time makers does not have to meet the same industrial safety standards as big companies do, so we can buy some gear that you may have to make yourself over there. With that said a LOT of guys still make their own stuff on this side of the pond.

89Likes

89Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote