Results 71 to 78 of 78

Thread: Cable damascus?

-

07-01-2015, 07:10 AM #71

I am curious if the bandsaw blades can be used for forging? These days, many of them are bimetal, with a soft core and case hardened only, just like cheaper files. In that case they may not be that useful.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

07-01-2015, 11:37 AM #72

Had a play with about 6 pieces tonight to see if they would forge but the outer ones kept cold lapping and coming unattached even with borax

also flatterened out 1 of the cables only hand hammering,

I can see some strands have cold laminated, but will see how it goes, they are cooling in vermiculite for the night to anneal them.

May need to do these at work with the 50t press in future.Saved,

to shave another day.

-

07-01-2015, 08:54 PM #73

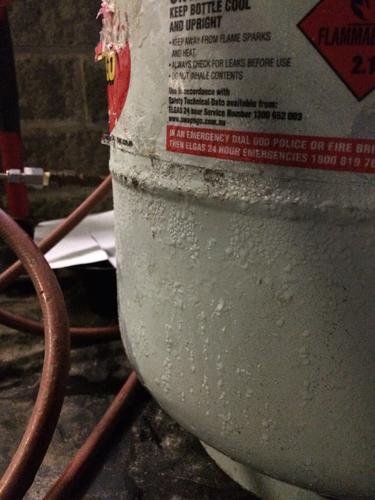

from this - condemned lifting slings

to this - cut & ends welded

to this - first twist

to this & bit more heat

to this - hand hammered to about 2"x1/4" bar

to this - taken back to critical ( non magnetic) then in vermiculite to anneal overnight

A bit of gas removal happened, lucky it's not freezing here.

Saved,

Saved,

to shave another day.

-

07-02-2015, 12:15 AM #74"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I would not recommend those blades for pattern welding unless you are willing to do some preliminary work in the setup. They are most likely metal cutting blades and will most likely be of a backing material (the blade) of some variety of 6150 series steel with an impulse welded tooth of M2-M42 high speed steel or the like that contains cobalt or some other metal-cutting alloy.

The 6150 is not so bad. I welded some of this material into a billet and had a very difficult time cutting the billet into usable pieces with any other normal metal cutting tool (bandsaw, abrasive disk) in the shop. I finally hot cut the stuff using the forging tools and gave the customer the pieces. It forges okay but cold cutting it is a miserable job.

The preliminary work would be to grind off the teeth. When the spark changes color from reddish to normal looking yellow-white sparks the cobalt is gone and you're left with the 6150. It will give a fairly nice contrast in the etch.

I've not run across simple case hardened metal cutting blades. Bandsaw blades that are wider than 4 inches across, designed for cutting wood are more than likely to be near 15N20 in recipe and good for PW billets.

I know it's tempting to not throw out "perfectly good looking metal." In the end it won't be worth what you paid for it.

-

The Following 2 Users Say Thank You to Mike Blue For This Useful Post:

randydance062449 (07-02-2015), Substance (07-02-2015)

-

07-02-2015, 03:41 AM #75

at least it wont be worth less than I paid for it LOL

it was more for practice & playing

for the pieces I tried to weld last night I put the teeth on opposite sides for each layer

don't want to kill good steel trying to get something to workSaved,

to shave another day.

-

07-02-2015, 05:52 AM #76"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

You can hope that the nasty bits will scale away by the time you're done building up the billet. And you can erase the rest grinding to profile. It's only a few thousandths of tooth. You could be good to go by then.

The manufacturers aren't going to put more money in than required to make the saw blade into an efficient tool for what the engineers expect as it's lifetime of use (but then, you have to buy another one right?).

Make a blade and test it. If it's close to 6150, my research into blade manufacture indicated, and a little better carbon from the cable, the average carbon content should be enough for a decent to better razor blade. Patterns are subject to more variation and less predictable sometimes.Last edited by Mike Blue; 07-02-2015 at 03:46 PM. Reason: clarity

“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

07-02-2015, 09:23 PM #77

the saw blades were a fail hand forging the were laminated, when I cut the outer edges off the blades were fair easily broken apart with a few love taps from my 3lb hammer

some areas were fused but not solid

the cable seams to have faired better results so far

a rough shaping so far until my dodgy little belt grinder gave up the ghost

Last edited by Substance; 07-02-2015 at 09:28 PM.

Saved,

to shave another day.

-

11-11-2015, 02:03 PM #78Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

One thing about using 20 Mule Team Borax is to make sure it is just that Borax ONLY! They make a product called Boraxo which has laundry soap in it besides the borax & that product WILL NOT WORK!

Slawman

-

The Following User Says Thank You to Slawman For This Useful Post:

randydance062449 (11-11-2015)

105Likes

105Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote