Results 1 to 10 of 57

Thread: New 72x2 Grinder WIP in Aus.

Hybrid View

-

07-31-2015, 08:49 PM #1

-

07-31-2015, 09:34 PM #2

I don't think more than a minute per razor. I do all of my rough grinding at one speed, and all of my post HT grinding at another. It takes less than a minute to move the belt to a different set of pulleys. I would only be changing the drive wheel for something out of the ordinary, and even then it would not take very long.

-

08-05-2015, 03:15 AM #3

I've got similar thoughts for my new grinder, but going with the little buddy style of pullout flat platen (with 2" wheels). For hollow (at this stage) I can get an 8" wheel for $30. Not designed for this application but saw someone using it on facebook. Cast metal construction with urathane 'tyre', grease point, and rated to 350kg of load. I do like the idea of the small wheel mount, they are genius for small radii, and using them on a radiusmaster has proved their worth. I've also gone with a 2800 rpm motor and locally sourced VFD (both from WEG).

Looks like a good build so far.

I'm going to need a bigger bathroom

-

08-05-2015, 11:06 AM #4

I originally looked at the WEG set ups also but they were over double the price

Saved,

to shave another day.

-

08-05-2015, 11:29 AM #5

-

08-06-2015, 08:58 PM #6

some crucial pieces for the puzzle as I had a long awaited package arrive today from Sunray

Also got a bit more progress done on the body the other day, hopefully will get the motor mount drilled & welded on this arvo also all going well.

Saved,

Saved,

to shave another day.

-

08-18-2015, 08:54 PM #7

Aaaahhh the sacrilege, had to work the weekend

along with 12 hour plus days for the last week odd & the rest of this week, be alright if I got paid for any overtime.

along with 12 hour plus days for the last week odd & the rest of this week, be alright if I got paid for any overtime.

either way back on track

unfortunately not much fab completed on the grinder since the last post, but I have got all but 1 of my drill bits & taps found ready,

Bonus was I got home last night & had a parcel from GAMECO on the table to open.

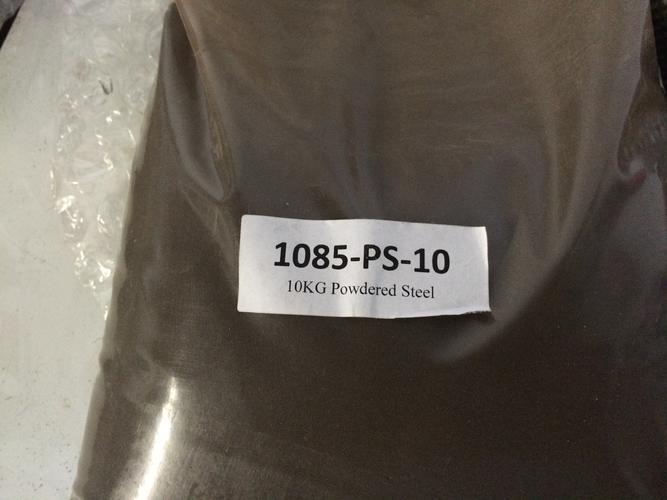

an assortment of 72x2" belts to, some steel marking dye, some forging tongs, & a great deal on some Powdered 1085 metal to experiment with later down the track.

hopefully everything will be back to normal early next week so I should get the time to finish the grinder off .

.

Last edited by Substance; 08-18-2015 at 09:00 PM.

Saved,

to shave another day.

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

but went with it anyway.

but went with it anyway.