Results 1 to 10 of 57

Thread: New 72x2 Grinder WIP in Aus.

Hybrid View

-

06-15-2015, 08:46 AM #1

New 72x2 Grinder WIP in Aus.

New 72x2 Grinder WIP in Aus.

Thought I might as well do a progressive post for my grinder WIP

So some of Aussie member may benefit from sources etc

progress so far

1st I spent the last couple of months searching the net for every grinder I could find to plagiarise for my design.

I have narrowed it down to a couple of design options,

My final design criteria is as follows:

VFD operated - for more control

Direct drive 1.5kw/2ph motor - 3 phase

8" & 4" wheel on a swinging mount

A platen between the wheels for flat work

a small wheel attachment with a 2", 1" & 1/2" wheel options

5" drive wheel - crowned

3" tracking wheel - crowned

Strut Type spring -15kg/33lb

50x4mm box section body & arm mounts x 3 off

40x5mm box section wheel & tracking arms

finally budget about $1300 Aus.

I have done a couple of drawings for design scale etc

ok so far ordered the following:

motor -$ 185 delivered Connon motors in Victoria

VFD - $155 eBay seller 2 year warranty ( the rest have only 1 year for $137)

5" drive wheel solid Ali & small wheel attachment with 2", 1" & 1/2" wheels from eBay $250

3" tracking solid Ali, 8" & 4" contact wheels Ali core with 70 dura lining from Sunray - waiting final price and shipping to order tomorrow hopefully (about $400)

Some knob and screws $14

budget spent so far

$185

+$155

+$250

+$ 14

+($400) tba

=$1004 and counting

Part 1 received

Last edited by Substance; 06-15-2015 at 08:57 AM.

Saved,

to shave another day.

-

06-15-2015, 09:51 AM #2

Skipnord has a massive setup. 2 horse 3ph 220 motor, variable speed drive, 2x72 (IIRC) belt.

If you don't care where you are, you are not lost.

-

06-15-2015, 03:34 PM #3

When I built mine I was going to use a crowned drive wheel also, but the friend who made it for me questioned it and said that his drive wheel was not crowned and his thought was that it shouldn't be. I went with his suggestion and the grinder has always tracked perfectly.

What is the top RPM of your motor controller combo?

-

06-15-2015, 04:31 PM #4

My drive wheels are crowned slightly. It's not strictly required, but it makes it easier to get them to track correctly.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-15-2015, 05:24 PM #5

A flat drive/tracking wheel with a piece of tape around the center is also a good option.

Charlie

-

06-15-2015, 09:00 PM #6

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-15-2015, 10:11 PM #7

part of the problem with the drive also, is the limited options for Ø24mm shaft

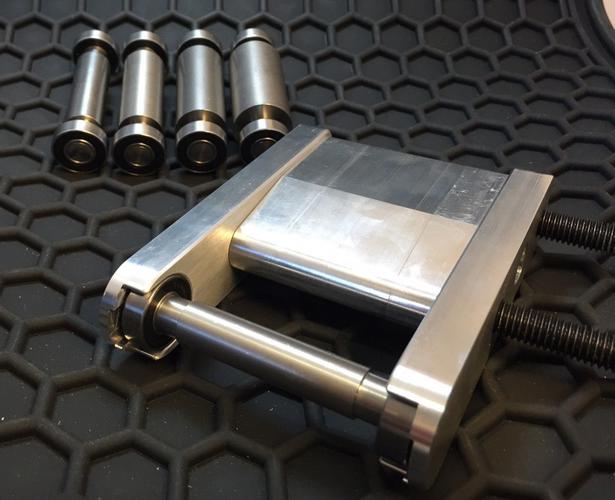

This is the Drive & small wheel set up on its way

Saved,

Saved,

to shave another day.

-

06-15-2015, 09:50 PM #8

I went the 4 pole 1400 RPM motor mate

projected speeds are as follows:

VFD Motor

RPM - Final drive Ø " - belt speed FPM - Grinding

250 - 5 - 327 - Finishing

500 - 5 - 654 - Finishing

1000 - 5 - 1308 - Hollowing

1500 - 5 - 1963 - Profiling

if I can get more than 1500rpm from the VFD even betterLast edited by Substance; 06-15-2015 at 09:59 PM.

Saved,

to shave another day.

-

06-16-2015, 01:14 PM #9

It's good that you have an idea of what you want, but as soon as you get started, toss the numbers out the window and see what works for you. Go by what you see and feel and experience when you grind. It will depend on the steel, and the design, and the belts, and the size of the contact wheel and how you hold the blade, and how fresh the belts are.

And there are things for which you want to use used belts, and things for which you use fresh belts.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

-

06-16-2015, 03:34 PM #10

The grinder I made is not VFD. My belt speeds are approximately 425, 850, 1700, surface feet per minute. I started doing finish work at 425, but now I rarely go that slow. I'm glad to have the option though. 1700 is adequate for roughing IMO. I could definitely go faster for roughing, but I doubt I'll ever change anything to go faster. All I would need is a bigger drive wheel.

If I had the whole thing to do over, I'm not sure at this point that I would change anything.Last edited by bluesman7; 06-16-2015 at 03:47 PM.

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote