Results 11 to 20 of 57

Thread: New 72x2 Grinder WIP in Aus.

-

06-15-2015, 10:53 PM #11

I think the 2hp may be at the higher end for Razors, since my 1/4hp handy grinder I can stop with very little pressure, but it still grinds away steel just a lot slower that's all

but my thought was that although I am primarily looking to use this for Str8s, if I want I can dabble with some knives also & it should still last forever as I doubt I will be putting big loads on it anyway.

but only the Future Me can answer that for sure, so Present Me is allowing for some play LOLSaved,

to shave another day.

-

06-16-2015, 12:12 AM #12

I got a 70A 14" wheel from them for doing slight hollow grinds on folders. Absolutely love it - be sure to talk to them about balancing though. I got mine balanced and tracks beautifully. A 70D might be too hard (you do want some give). Pretty sure my stock 4,6 and 8" wheels from usaknifemaker are 70A as well (and likely made by sunray for the prices).

-

The Following User Says Thank You to Joe Edson For This Useful Post:

Substance (06-16-2015)

-

06-16-2015, 12:14 AM #13

This was my specific order to be exact and then I talked to them about 70A vs D and went with A.

Outer Wheel Diamter: 14”

Wheel Width: 2”

Material: Urethane

Hardness: 70 Durometer Orange

Wheel Face: Smooth

Hub Material: Aluminum

Bearings: What is listed is fine: (2) 1616-2RS Ball Bearings (1/2” Inner diameter)

Wheel Surface Type: Flat

Wheel Corners: Sharp/Square

Balanced (they balanced at 3000 RPM)

-

The Following User Says Thank You to Joe Edson For This Useful Post:

Substance (06-17-2015)

-

06-16-2015, 01:14 PM #14

It's good that you have an idea of what you want, but as soon as you get started, toss the numbers out the window and see what works for you. Go by what you see and feel and experience when you grind. It will depend on the steel, and the design, and the belts, and the size of the contact wheel and how you hold the blade, and how fresh the belts are.

And there are things for which you want to use used belts, and things for which you use fresh belts.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

-

06-16-2015, 03:34 PM #15

The grinder I made is not VFD. My belt speeds are approximately 425, 850, 1700, surface feet per minute. I started doing finish work at 425, but now I rarely go that slow. I'm glad to have the option though. 1700 is adequate for roughing IMO. I could definitely go faster for roughing, but I doubt I'll ever change anything to go faster. All I would need is a bigger drive wheel.

If I had the whole thing to do over, I'm not sure at this point that I would change anything.Last edited by bluesman7; 06-16-2015 at 03:47 PM.

-

06-16-2015, 04:05 PM #16Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

My motor is a 1750, and I can go 200% with my variable drive, so 3600 max. Don't use it that fast very often.

-

The Following User Says Thank You to skipnord For This Useful Post:

Substance (06-17-2015)

-

06-17-2015, 10:00 AM #17

Thanks lads

The Belts speed are just references as they were originally based on using a single speed motor and pulleys to check my belt speeds were not going be to low for bulk removal and too fast for finishing.

Once I get started and used to it, I am sure it will be more grinding by feel as mentioned

Also placed the order for my tracking wheel & a 4" & 8" contact wheels with Sunray todayLast edited by Substance; 06-17-2015 at 08:52 PM.

Saved,

to shave another day.

-

06-17-2015, 11:31 AM #18

This speed talk got me thinking about my speeds. Since I rarely use my lowest speed and feel that my highest speed could be higher, it seems obvious that I should use a larger drive wheel. BUT that would raise my middle speed that I presently use for finishing and I feel that it is near it's upper limit now. If I raise the speed enough to make my lowest speed my finishing speed, then I lose the option of using a lower speed ever. Of course I could easily change drive wheels when needed. That could be about as fast as changing belts. Then there is the ~ $50 for the second drive wheel. In the end, the only benefit of using two changeable drive wheels would be to raise my hogging speed. I'll have to be doing an awful lot of hogging to ever make that expense worthwhile. Another hour wasted thinking about fixing problems that I don't have.

-

06-21-2015, 11:26 PM #19

VFD arrived on Friday

now to harass the Lecky's at work for wiring tips & help LOL

Saved,

Saved,

to shave another day.

-

06-22-2015, 12:11 AM #20

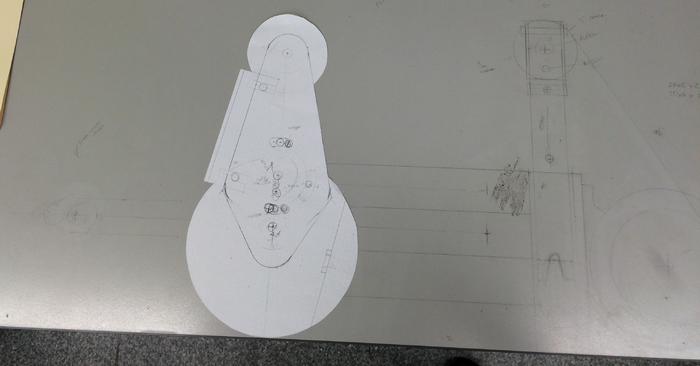

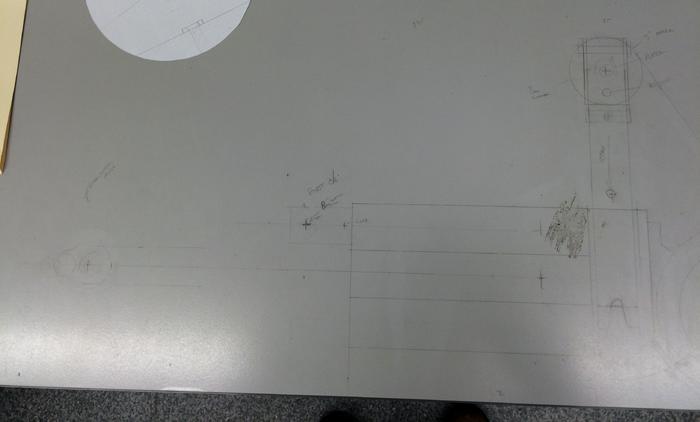

draw to scale my grinder design with 4" & 8" contact wheel swing arm platen & small wheel arm so I could get a real feel for sizes & design

if wondering, Yes I draw it on my drawings desk at work as A3 paper wasn't big enough LOL

Saved,

Saved,

to shave another day.

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote