Results 21 to 30 of 57

Thread: New 72x2 Grinder WIP in Aus.

-

06-24-2015, 10:01 PM #21

another box of bits arrived today

drive wheel & small wheel mount with a 2", 1" & 1/2" wheel

The Ali was al nice & clean & shiny until I got my grubby mits on them LOL.

great looking workmanship only a pitty that the drive wheel is not the 24mm bore ordered

so awaiting sellers response oh well a bit longer wait again LOL

still another couple of weeks of so before the Sunray contact & tracking wheels will be even made, so no time lost.Last edited by Substance; 06-24-2015 at 10:04 PM.

Saved,

to shave another day.

-

06-29-2015, 09:50 PM #22

some more progress with a bit of hand sanding to final fit, the drive wheel is fitted to the motor

so now I have real dimensions for final design of the mounting plates etc

Saved,

Saved,

to shave another day.

-

06-29-2015, 10:28 PM #23

Only 5 days to get the right wheel to you. Not bad service.

-

06-30-2015, 01:55 AM #24

No replacement required mate,

just had to do some minor sanding on the bore & shaft to remove some burrs creating misleading dimensions of a 4 thou discrepancy & all came up to spec

I had a local machine shop available to skim it if it was needed, to save the return trip but.Saved,

to shave another day.

-

07-15-2015, 01:47 AM #25

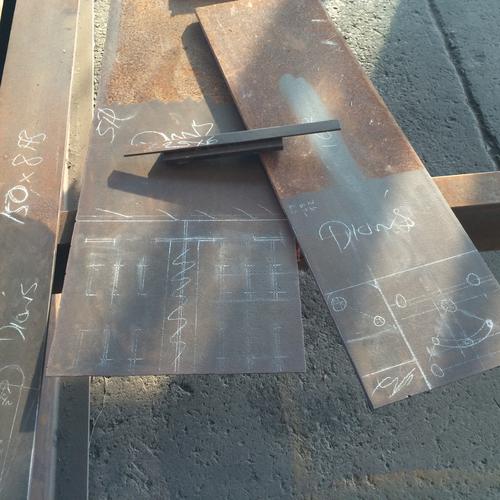

Steel marked out ready, ready for drilling & cutting

but now on hold as I just found out I am going to Mt Isa (Google that bucket of Joy if you want just enter Bum Fv<k nowhere Queensland, it will probably come up with pics) for the next week or 2 to do a Tender for work,

so apparently my real life is on hold, love the notice I get here LOL

Saved,

Saved,

to shave another day.

-

07-15-2015, 02:33 AM #26

Really enjoying your process Mate

....I'll be interested in the final costing too !!

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

....I'll be interested in the final costing too !!

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

-

07-30-2015, 02:26 PM #27

Well, times change. As my grinding skills have improved I don't see myself ever using that lowest speed and I decided that a higher roughing speed would be better, so I have a larger drive wheel coming in today's mail. The small drive wheel will live in the box with my contact wheels so I can just change back if I ever want that slow speed for anything.

New speeds will be approximately 850, 1700, and 3400 SFPMLast edited by bluesman7; 07-30-2015 at 02:34 PM.

-

07-31-2015, 08:49 PM #28

-

07-31-2015, 09:34 PM #29

I don't think more than a minute per razor. I do all of my rough grinding at one speed, and all of my post HT grinding at another. It takes less than a minute to move the belt to a different set of pulleys. I would only be changing the drive wheel for something out of the ordinary, and even then it would not take very long.

-

08-05-2015, 03:15 AM #30

I've got similar thoughts for my new grinder, but going with the little buddy style of pullout flat platen (with 2" wheels). For hollow (at this stage) I can get an 8" wheel for $30. Not designed for this application but saw someone using it on facebook. Cast metal construction with urathane 'tyre', grease point, and rated to 350kg of load. I do like the idea of the small wheel mount, they are genius for small radii, and using them on a radiusmaster has proved their worth. I've also gone with a 2800 rpm motor and locally sourced VFD (both from WEG).

Looks like a good build so far.

I'm going to need a bigger bathroom

81Likes

81Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote