Results 1 to 10 of 10

Thread: Input, Comments on Razor build

Threaded View

-

08-29-2015, 05:52 PM #1Member

- Join Date

- Aug 2014

- Location

- Shippensburg, PA

- Posts

- 70

Thanked: 12 Input, Comments on Razor build

Input, Comments on Razor build

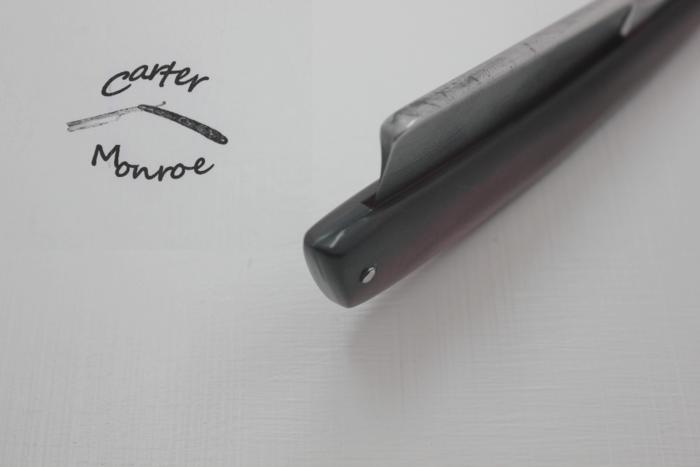

I am fairly new to this forum and like to mostly read about what the world of Straight Razors and current events regarding the such. I have for just a little while now have been making razor. I have been using mostly 01 just because of the economical factor the the fact that I went into it knowing that there was going to be just a small (sarcastic) learning curve. After working preforming restorations and scale fabrication for sometime now and really studying the geometry of razor I just had to try to make one. I also have been ready a lot but nothing in my opinion is as important as comments and feedback from others. I am posting a razor that I just finished. It was fabricated from Damascus steel (1095 & 15N20). It is 11/16 with a Spanish point laid in red horn scales. It really shaves nice and holds its edge well. I have found that the area in which I have to most problem in making a straight razor is the heel, particularly keeping it even. I am open to any feedback that is available about methods that could help with this or any input or advice for that matter!. Thanks!!

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote