Results 1 to 10 of 31

Thread: First edges -difficult for you?

-

09-21-2015, 01:42 AM #1

First edges -difficult for you?

First edges -difficult for you?

Hi all,

Just wondering if you guys tend to find the first edge you put on a razor difficult to achieve?

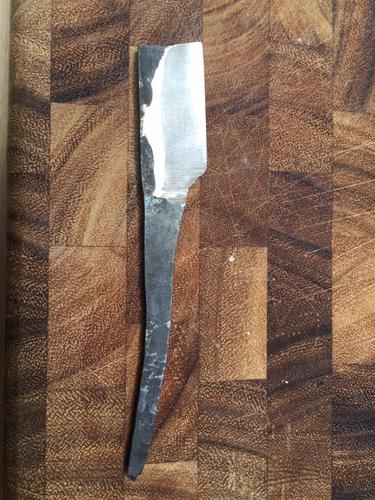

I have a neat forged kamisori project in O1 (which turned out to be ground left-handed) that has amazing looking alloy banding (not sure that's a good thing). It may be a bit narrow, or a million other things could be wrong with the heat treat or temper, but I was getting a lot of foil edges etc.

I started with diamonds 325, 1000, then 1k chosera and then every stone I could find.

-

09-21-2015, 02:00 AM #2

When I get a new old razor that I use the sand paper on and buff a lot the first edge I might as well not try to shave with. so far the first edge I get needs re-honing. I believe this is because I fail to get the bevel set properly. on these blades I start out with 400 then 1-3-5-8-12K naniwa and finish with the 20. I really need to invest in a scope or better magnifying glass.

-

09-21-2015, 02:02 AM #3

Sounds reasonable. This is a homemade razor. Takes a serious grunt to grind down tool steel to a cutting edge.

-

09-21-2015, 02:10 AM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

Well, the first few were surprisingly easy. There were many that followed that were so much more challenging. I never use diamonds for regular honing. They are very aggressive, many believe they leave very deep stria and cause chipping later in the progression. To be honest I just took their work on it. If you message Jon, thisisclog, he is in Edmonton and very experienced. I'm sure a get together would be easy. A kamisori can be a little tricky. I know he has done a few.

On western straights, even ones with restorative honing, I typically use a 1K Chosera, then Norton 4K,8K and then a slurried finisher. I use a loupe to check my razor every step of the way. Until you have a perfect bevel nothing else matters.It's not what you know, it's who you take fishing!

-

09-21-2015, 02:14 PM #5

-

09-21-2015, 03:01 PM #6

Or a mix of the two!

I think the angle is a bit steep (ended up a bit thinner than planned), and my oven overshot the temp again and went to brown/purplish.

-

09-21-2015, 03:16 PM #7

-

09-21-2015, 03:48 PM #8

-

09-21-2015, 04:05 PM #9

Gold is good...

-

09-21-2015, 08:36 PM #10

When I first started I had a hard time getting the first good edge.

I have been setting the bevel during the grinding process now days, it makes the process a lot easier.

In the early days I would also not grind off enough of the decarb-ed metal. It would take a lot of honing to get down to the good metal.

My lessons learned and what works best for me are,

A) set the bevel as part of the grinding process

B) leave enough metal width wise so that I can grind away the width of the blade a little bit.

Charlie

-

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote