Results 1 to 10 of 65

Thread: O1 heat treating problem

Hybrid View

-

11-19-2015, 10:23 PM #1

Since we are talking heat treating O1, here is what I wonder about.

How much soak time (in a stable temperature) at critical temperature is needed for the alloying elements to fully diffuse?

Do the alloys need to be fully diffused to take full advantage of the properties of O1?

I always err on the side of too long a soak time with O1, hoping to get all I can out of the steel.

Charlie

-

-

11-20-2015, 03:36 AM #2"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Okay. Keep O-1 simple.

It's a simple steel despite the small amounts of alloying elements. The specifications by Carpenter, and other companies, is five minutes per inch of thickness. A razor is not an inch thick. Maybe an inch wide, but like any blade it's a tapered triangular section that does not fit well into the steel company's rituals for testing Blocks of steel. I use five minutes to give the carbon time to go into solution since it's the chemical that forms the carbides. All the other stuff in there does not move around so easy. If all the carbon does not go into solution it can affect the result. Usually a non optimal hardness, or grain reduction. It depends on what you intend to achieve.

A long soak, if the temperature of the fire is too hot, could coarsen the grain. A long soak at a stable accurate temperature below the coarsening temperature theoretically could be held for a long time. But you could lose carbon and other degradation via scale depending on exposure to the right atmosphere. Or if the atmosphere is reducing, eg carbon rich, you could add carbon to the steel. About 1mm depth at 4 hours at 925C is a round set of numbers for the time at temperature to achieve this. A scale preventer could be helpful in such cases.

Gregg: the two hardness numbers are probably a range for the values obtained during testing of many samples (low/high) for that temperature.

As to the number of tempering cycles, simple steels do not require complicated rituals. Two cycles at one hour each still equals two hours. A tempering cycle is meant to reduce the hardness or increase toughness/less brittleness of a crystalline structure that developed from a violent quench. Did you know that martensite forms at the speed of sound? In a thin section blade like a razor imagine 700 mph over 0.8mm distance. I can't think of a more shocking event to such a thin section of material. Allowing the blade to equalize to the temperature of the quenchant, say over 10-40 seconds is about too fast to count. The violence is over before you can even think to stop it. As was said, pulling the steel out too soon, could have enough residual heat to affect hardness at the edge but there isn't much mass behind the edge in a razor. It's not a large worry in my mind. A big knife, or a chisel or other tool...could be enough though.

-

The Following 4 Users Say Thank You to Mike Blue For This Useful Post:

gregg71 (11-20-2015), ScottGoodman (11-20-2015), spazola (11-20-2015), Substance (11-23-2015)

-

11-20-2015, 04:18 AM #3

My understanding of the two temper cycles is that on cooling from the first cycle, retained austenite is converted to fresh martensite and the second cycle tempers this fresh martensite.

-

-

11-20-2015, 06:30 AM #4"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Multiple tempering cycles were fashionable long before retained austenite became a discussion topic in heat treatment. There are some legendary tales that tempering pauses must be at least 24 hours between cycles.

RA is less of a problem in eutectoid steels and there is more RA with higher carbon content and other alloys at higher temperatures or poor adherence to the controlled heat treatment of a steel requirements of a particular steel. If the material is prepared for HT and heat treated as recommended, RA can be minimized. Things like cryogenic treatment have their place in reducing RA (and require multiple tempering cycles) when conditions are right. You might not get rid of all of the RA despite doing everything exactly right. Sometimes RA is a desirable structure as it's tougher than martensite.

-

-

11-20-2015, 06:05 PM #5

Mike,

thank you for thet details. I will ask for more things soon.

Bad news: retempered, regrinded, repolished, rehoned and reshaved but it does not work. The edge is too sensitive, wear out during the shaving.

The edge is too sensitive, wear out during the shaving.

gregg

gregg

-

The Following User Says Thank You to gregg71 For This Useful Post:

ScottGoodman (11-21-2015)

-

11-20-2015, 06:21 PM #6

-

The Following User Says Thank You to bluesman7 For This Useful Post:

gregg71 (11-20-2015)

-

11-20-2015, 07:24 PM #7

I think they were right. I suspect to the thinly grind edge (0.8 mm) before the HT. Because the situation has improved, that took off the edge but not enough.

Yest. It is perfect, 16° with one layer of tape.

Just do not practice the heat treatment. It has made by other master.gregg

-

11-20-2015, 06:24 PM #8aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

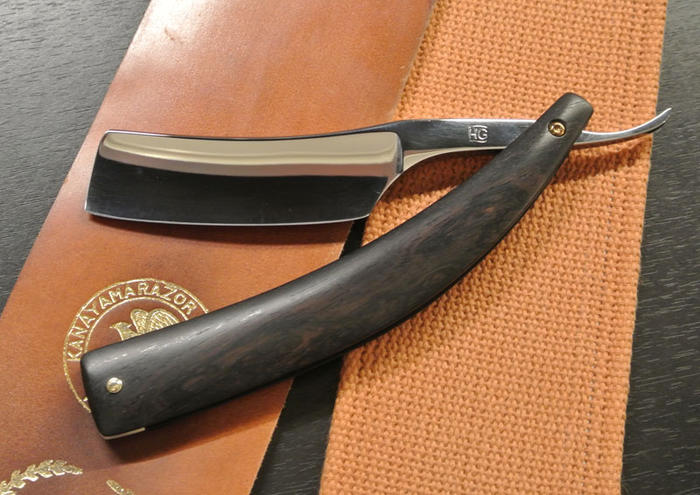

Sure looks good, hate it that it just has no soul. I've done it quite a few times my friend. Last batch of knives I made I warped one, tried to straighten...snapped it. Best I did anyways, it was grainy.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

gregg71 (11-20-2015)

-

11-20-2015, 07:26 PM #9

-

11-20-2015, 07:12 PM #10

Lovely looking razor. Pity about the issues you are having.

Tony

88Likes

88Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote