Results 1 to 10 of 65

Thread: O1 heat treating problem

Hybrid View

-

11-23-2015, 09:06 AM #1

Sorry I misunderstood this. I do not use such a compound. It sounds good. How much influence the standard HT process? What brand would you recommend?

What do you mean preheatin? The furnace, end/or quenching oil?

Thank you for your useful advices!gregg

-

11-27-2015, 01:42 AM #2aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

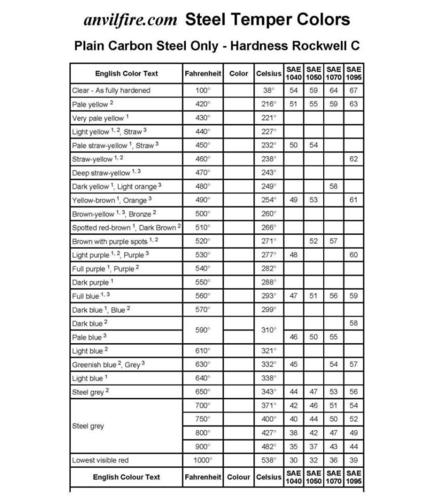

Here is a useful chart for you. If it is not clear enough for you, pm me your email and i will send it to you via email.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

gregg71 (11-27-2015)

-

11-27-2015, 07:55 AM #3

Thank you so much, it is very useful for me. But just now it was broken the thermocouple in the furnace.

Yesterday ordered a new one.

Yesterday ordered a new one.

An other useful pic from the Wikipedia:

gregg

gregg

-

12-02-2015, 06:29 PM #4

It seems to succeed. I will refine the edge, but everything looks good.

This is worked for me:

I leaved 1.5 mm thikness of the edge.

soaking: 805C / 1480F, 8 min.

quenching oil: 50-60C / 130F, 20 sec

tempering: after cooling to room temperature, 200-205C / ~400F, 2x1h (between cooling to room temperature)

After the shave test:

Thank you for all the help!gregg

-

The Following User Says Thank You to gregg71 For This Useful Post:

ScottGoodman (12-03-2015)

-

12-03-2015, 02:29 AM #5aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Blade looks great! Sounds like you got it right this time.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

12-03-2015, 08:01 AM #6

Thank you very much!

....and couple of hours later (sorry for the bad pic):

gregg

gregg

-

12-11-2015, 11:32 PM #7

Update!

I created the original razor again.

My process:

I leaved 1.5 mm thikness of the edge.

soaking: 805C / 1480F, 8 min.

quenching oil: 55C 20 sec

tempering: after cooling to room temperature, 210C 2x1h (between cooling to room temperature)

After this I sanded a few tenths of millimeters from the edge.

Conclution after the test: I got the best, smooth, sharp edge ever. I am very happy, and thank you for your help!

The owner is also very satisfied with the razor.

gregg

gregg

88Likes

88Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote