Results 1 to 10 of 12

Thread: Edge thickness?

-

02-09-2016, 02:38 PM #1

Edge thickness?

Edge thickness?

Just wondering what some of you builders take your edge down to before honing a razor? I recently destroyed my 2nd attempt at a razor build. I took it down to 0.005, which I thought was ok, I do kitchen knives pretty damn thin too sometimes, but this razor I could actually bend and break the edge with my finger nail. I assume I botched the HT on it (I run an evenheat kiln) but this is the first for me have a blade be so messed up. Bummer to because I was almost done! Everything seemed as usual right up to the last few grits of hand sanding. Live'n learn (and cry a little.)

-

02-09-2016, 02:39 PM #2

-

02-09-2016, 03:51 PM #3

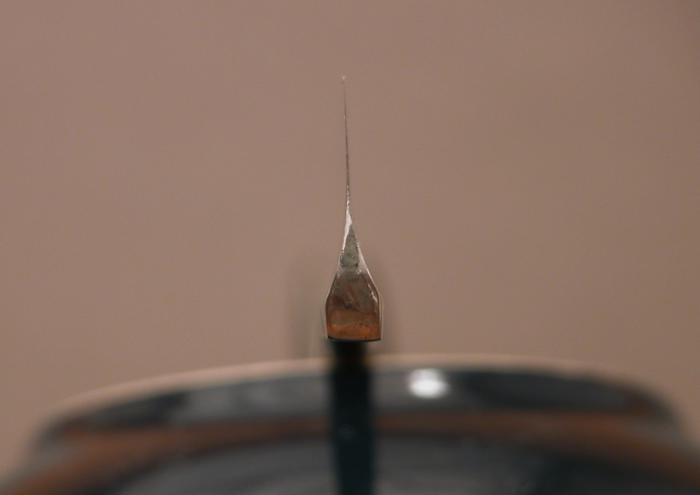

I have been going to .004" or .005" on post HT grinding with about .010" 1/4" back from the edge.

-

The Following User Says Thank You to bluesman7 For This Useful Post:

spazola (02-16-2016)

-

02-09-2016, 04:05 PM #4

Yea I definitely messed up the heat treat somehow. I have no idea how or where though, I just did the usual. 1500 in the evenheat, 130* canola, 2 temper cycles at 400. I have another razor I made at the same time as this, only rough ground so far, so I'm going to redo the whole HT process.

btw That looks sweet, bluesman! What size wheel do you get in there with? I only have a 5" for my smallest right now

-

02-09-2016, 05:17 PM #5

-

02-09-2016, 05:35 PM #6"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Curious minds want to know the steel type?

-

02-09-2016, 07:36 PM #7

-

02-09-2016, 08:04 PM #8

1084, which is supposedly fool proof heat treat haha I usually use O1. I've never had this problem with anything else I've made in the past (my limited experienced 2 year knife making past) but I still dont really understand what is going on here with my razor.

-

02-09-2016, 10:12 PM #9"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

1084 has enough manganese to through harden under normal circumstances. I suppose that is what some imply is fool proof. Your temperatures are in the right range. 1084 only requires maybe 2-3 minutes soak time before all the carbon goes into solution and the oil quench temperature and tempering temperatures are in the right ranges.

Is this a forged blade, then ground clean, or stock removal? Forging potentially opens the possibility of decarburization. The very edge would not harden since the carbon is lost to the forge environment. Maybe you can experiment with this blade and use the stones to clean off the weak edge and see if it feels like it's getting harder a little past the edge you now have. You should be able to feel it firm up on the stones.

Even if this piece of steel wasn't forged, there can be differences that cause a lot of head-scratching from bar to bar and even from one end of the bar to the other when no other shop practice has changed.

-

02-10-2016, 11:00 PM #10

Thanks Mike, this was stock removal

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote