Results 41 to 50 of 65

Thread: Planning a new little forge.

-

10-21-2013, 06:54 AM #41Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Yeah it is a cleat somebody is trying to sell as an anvil. pfffffff

I got this one.

Had to drive 200 miles to get it but is nice. 110 lb. Wilkinson from Dudley, England. I'd date it circa mid-1800s. It was bought new for the Duvall Copper mine in Kingman Arizona. When the mine closed a scraper bought it. I got it from his son.

It's going to get a new stand tomorrow.Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-21-2013, 12:20 PM #42

Ok I get it.

tongs in the fire -> not a good idea. They will get soft and lose grip. They'll bend like a noodle if you try to grip your piece. In fact, it'll be worse. If the tongs are plain construction steel whle the blanks are tool steel, you might end up burning your tongs (literally) by the time your tool steel hits welding heat.

the bracket thingy will work. Just be sure to make it out of something that won't melt or burn during extended periods at welding heat.

If you make it in metal, you might be in for a surprise Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

10-21-2013, 03:14 PM #43Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184 Good judgment comes from experience, and experience....well that comes from poor judgment.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-21-2013, 03:36 PM #44Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Another possibility is to temporarily weld a piece of rebar to the tail of the razor blank, as a handle. You can hold it with your bare hand, and don't have to mess with tongs. You would need to add a support to the outside of the door end of the forge to support it.

-

10-22-2013, 03:16 AM #45Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184 IT'S ALIVE !!!

IT'S ALIVE !!!

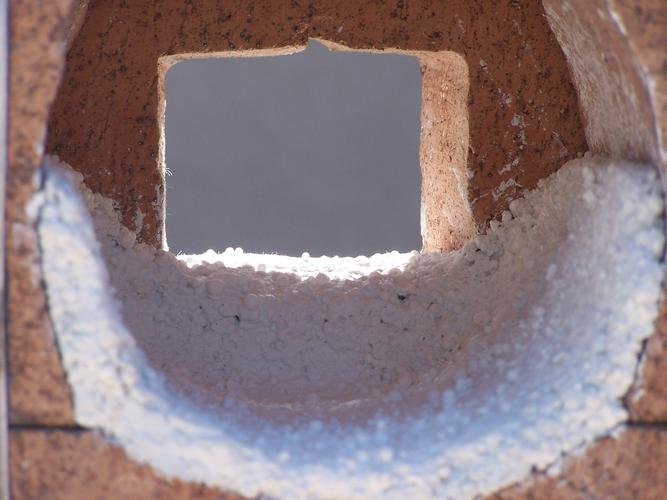

Well today went well. I got up late but made up the time with some planning.

I mixed up the clay (Bubble Alumina) and went to town. It definitely was named right. The little bubbles are everywhere. The consistency was no where near what I expected and so I only did half the forge. The bottom is what counts for this type of clay anyway. I have 4 pounds of Satanite and I guess I will use that to do the top tomorrow. I hope the Satanite is more like the clay I know. I may have to stand to forge on it's head but I will get the top done. Too much heat comes through the cracks of the brick to the shell which is thin sheet metal. How do I know ? :<0)

Well while the clay set for 3 hours I ran to my metal supply guy and picked up some scrap to make an anvil stand. I got back home and whipped this out. It needs some things still, like I have to come up with a cool way to hold the anvil down and make a few hammer hangers and a tong rack. But it works . How do I know ? :<0)

I fired it up to finish the clay cure. According to the info where I bought the stuff after 3 hours you finish the cure by starting the forge and slowly bringing it up to max heat. So you can't see much in this picture but if you look close you can see the blue flame. This is as low as it will go and I let it sit there for about 20 minutes while I grabbed the rest of the stuff. What stuff ? :<0)

It got freaking HOT quick !! Then I turned it up.

Video coming soon ......apparently it was too big :<0(Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-22-2013, 03:49 AM #46No that's not me in the picture

- Join Date

- May 2013

- Location

- Los Angeles South Bay

- Posts

- 1,340

Thanked: 284

Nice work. I bet your neighbors are like "what in the Sam Hill is this guy doing".

I love living in the past...

-

The Following User Says Thank You to RoyalCake For This Useful Post:

10Pups (10-23-2013)

-

10-22-2013, 06:16 AM #47

For reduced sound, put some thing between the anvil and the stand, then lock the anvil to the stand (as opposed to just placing it on top).

And also fill the legs of the stand to dampen vibration. I think Mike mentioned filling it with sand and oil. I've also seen a guy use PU foam.

You'll get a lot less ring in your anvil that way, which is good. Hearing issues aside, Less noise means less annoying the neighbours. And keeping on good terms with your neighbours is priceless.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

10Pups (10-23-2013)

-

10-22-2013, 01:45 PM #48aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I have also read that if you place a large magnet it will help with the ring. I've been eyeballing the 112 NC pound anvil from Centaur Forge, your full service farrier & blacksmith supply company myself. What have you read negative about it? I broke down yesterday and ordered a 3 burner deluxe knife maker forge from Gas Forge & Blacksmith Forge – Farrier Equipment | Majestic Forge yesterday. $73 bucks for shipping

I truly appreciate your sharing your journey with all the pics, very educational.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

10Pups (10-23-2013)

-

10-22-2013, 02:47 PM #49

-

10-22-2013, 04:02 PM #50"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

61Likes

61Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote