Results 61 to 65 of 65

Thread: Planning a new little forge.

-

10-23-2013, 03:54 PM #61Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

There is something about the sound of your forge that doesn't sound right. Also, there was one point when the fire went out, and then re-ignited. And, it seemed to me to take too long to heat up your steel. The flame sounded better at the end when you experimented with moving the air control sleeve, and added more air. When my forge, which is about the same size as yours, is running right, the sound is steady, not pulsing. I hope that makes sense - ask if it doesn't. You definitely are on the right track, you just need to experiment with various was to tune it. And, get your steel hotter before you start hammering. Good luck.

-

The Following User Says Thank You to skipnord For This Useful Post:

10Pups (10-24-2013)

-

10-23-2013, 07:07 PM #62

1) it needs to be hotter. when you pull out the stock, it barely seems past red hot. For really shaping steel, you should go way hotter. And in any case, your forge should be able to turn it light yellow in a reasonable timeframe.

2) you need some kind of support to lay your workpiece on.

3) you hammer with just your wrist. this is a good way to develop tendonitis + you get very little work done per stroke. You should lift the hammer higher, and use your wrist, elbow, and shoulder all together, with the wrist just doing the coordination of the hammerhead and not much more. you only have a short interval in which your workpiece is hot enough, and you want to move as much metal as you can within that interval.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

10Pups (10-24-2013)

-

10-23-2013, 07:37 PM #63aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Actually $ is an issue, but every dang time I try to save a buck it costs me as much as one commercially made, possibly more, and a huge loss of time. I started my nwg 2x72 grinder a long time ago and just recently got it going. I could have bought one for as much as I have invested in it. Bad motor (bought it new) & bad vfd (bought new) and not knowing enough about vfd's (finding someone was impossible for me too) & how to troubleshoot them costed me another new motor & vfd. Time had run out on warranties since I didn't buy them both at the same time. Time is another issue all together...I have very little of it & try to spend it wisely, thus ordered the forge after research the dickens out of them.

Problem with all these folks around here is that there are quite a few anvils around...just nobody will let go of one. I have three anvils that I can "borrow", but none that I can just buy. I hate borrowing stuff, once again Mr. Murphy is always hanging around and I would hate to somehow damage an anvil or have one stolen. That's the kind of luck I deal with when I borrow stuff...I may try an ad, gotta re-plenish my play $ though as I am actually overdrawn with the forge. I put it on credit card and had almost all of it stuck back...but will NOT buy an anvil until I have the forge paid for and at least half the $ sitting aside for the anvil if I go new. Took me a LONG time to get out of CC debt & not going to get back there over "stuff".Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

10-23-2013, 11:45 PM #64Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

+++1 on cash basis oasis. I was really thinking smaller anvil at first. 35 to 70. That and a good stand will make razors. Then there is always a big flat plate to use until you caught up on the flow.I do not borrow either. The words just don't come out of my mouth. And the offers always have a tone of " because I would like to borrow your ***** someday" and I never get "my ***** " back.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-24-2013, 12:59 AM #65Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Thanks for all the tips. I was only halfheartedly smacking the steel and I realize when I get down to business I will have to develop some skills. Your advice is going to help a lot.

I was thinking I probably don't need to turn that thing up all the way either. Less gas more air did make it sound better. At first I was thinking the breeze was making it stroke like that. I have some square tubing to make a tray/holder on the door and still have to make something for the inside when I start playing with RSOs . I am taking a few days off from it now but will get back to it soon.

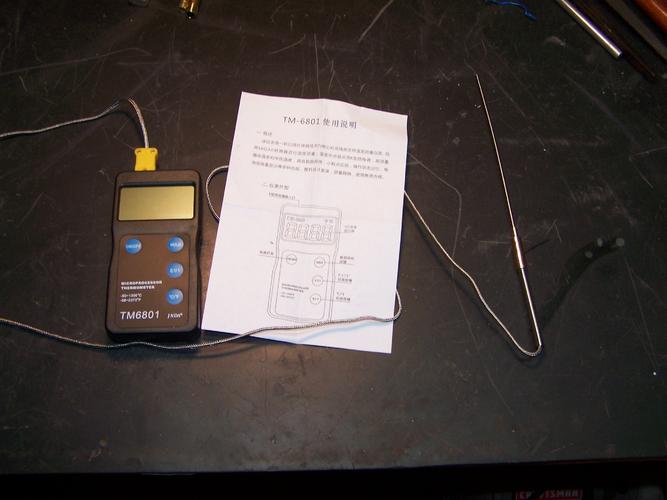

I did get this in the mail today.

-58 to 2,372 degrees +- 2% reading.

I am thinking of making a square tube that goes all the way through the forge to put razor blanks in for heat treat. I will have to get good at tuning that burner before I go there.

Once again thanks for the help!Good judgment comes from experience, and experience....well that comes from poor judgment.

61Likes

61Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote