Results 1 to 10 of 36

-

04-11-2013, 07:36 AM #1

The correct Blade hardness 01 for razors

The correct Blade hardness 01 for razors

How to temper the steel 01 for razors?

Please share your experiences.

Interested in temperature and time to each stage.

The forum did not find the appropriate topic

Maybe I'm bad searched?If something is unclear in the text, please correct me ......

-

04-11-2013, 02:26 PM #2

I usually temper O1 at 400F. I temper right after quenching. I temper twice an hour each time.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

GVIkzn (04-11-2013)

-

04-11-2013, 02:51 PM #3At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,114

- Blog Entries

- 1

Thanked: 13249

Sits back and pulls up a chair,,, waits for the hardness numbers

Sits back and pulls up a chair,,, waits for the hardness numbers

-

04-11-2013, 03:04 PM #4

Thank you!

1)Process 2)Temperature 3)Holding time 4)Environment

- 1)annealing 2) ...... 3)...... 4)....

- 1)normalization 2)...... 3)...... 4).....

- 1)quenching 2)...... 3)...... 4).....

- 1)temper 2)400F 3)2 * 1 hour 4) air

I hope that the processes are properly written and understandable

Soon we will reach the truth ofIf something is unclear in the text, please correct me ......

-

04-11-2013, 03:57 PM #5

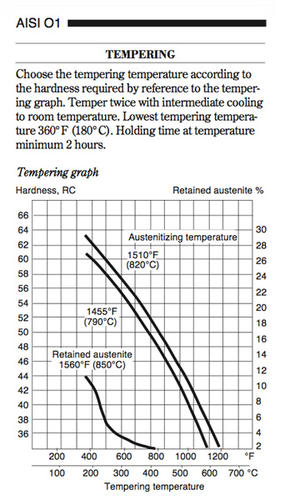

This should help too

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

-

04-11-2013, 06:58 PM #6

Thank you. it complies with the previous post.

Very interested in holding time during hardeningIf something is unclear in the text, please correct me ......

-

04-11-2013, 07:08 PM #7Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Do any of you pros test RC? is there a non destructive of doing so? today

-

04-11-2013, 07:16 PM #8

No I don't test, for the simple reason of not having a hardness tester.

Hardness testing (Rockwell C) is non destructive.

I sparktest the blade and the edge in particular.

If I get a nice shower of sparks, I know the heat treatment was successful.

I choose the tempering temp to end up with an expected hardness. It may differ by a point, but when all is said and done: it doesn't matter that much whether the hardness is 61 or 62.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

04-11-2013, 07:25 PM #9Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

04-11-2013, 07:43 PM #10

I only test the HRC when I get a new batch of steel, doesn't matter if it's coming from the same company. They sell hardness testing files that range from Hrc 40 through 65. They come in a set of 6 and increment by 5 HRC. That can give you a basic direction. There's are also standing or portable handlheld models that are more precise but cost much more and need to be calibrated every so often.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

pixelfixed (04-11-2013)

22Likes

22Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote