Results 1 to 10 of 19

Hybrid View

-

04-23-2013, 11:17 PM #1Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

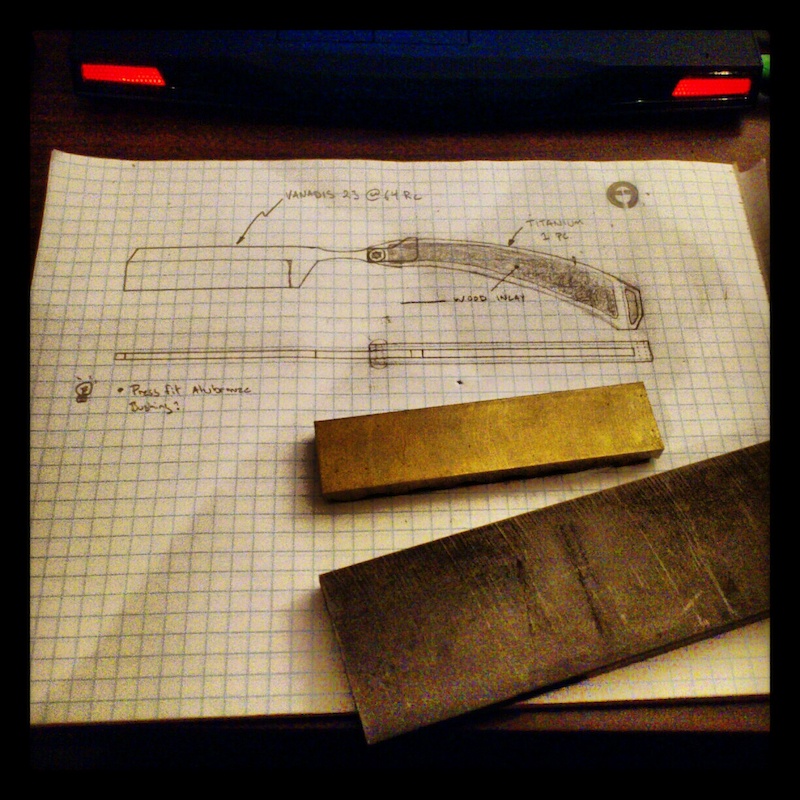

Thanked: 2 Spare time project - Vanadis 23 & Titanium

Spare time project - Vanadis 23 & Titanium

This thread can serve as a build diary of sorts for something I've wanted to make for a while:

More to come as I have the time to work on it.

-

04-24-2013, 06:02 AM #2

If that is going to be the thickness of the blade, it is going to be much too thin. The angle should be around 15 degrees.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

04-24-2013, 10:40 AM #3Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

Thanked: 2

Agree. It's .125 in that sketch. Thinking .187 at the spline. What do you think. It will be a wedge grind. Of note, even a .187 on a 9" oal fighting knife is very stiff. The material I'm using for this is vanadis 23 which I've already heat treated to 64Rc.

Last edited by AFisher; 04-24-2013 at 10:49 AM. Reason: additional info

-

04-24-2013, 12:21 PM #4aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Starting out with pre-hardened steel? No way I would want to start out with some .250 flat stock that was already hard, especially the stock removal for the hollow...

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

04-24-2013, 12:38 PM #5Senior Member

- Join Date

- Dec 2011

- Location

- I'm Gonna Spend Another Fall In Philadelphia

- Posts

- 2,010

Thanked: 498

Shooter is dead on correct.

I once made a razor out of an old hand file. I never annealed it. Must of been in the 60's Rockwell. Not only did it take a lifetime to grind, I was always sweating bullets trying to keep the bloody thing from burning up, and loose temper. Especially when I was getting close to the finished thickness. I could barely keep up keeping it cool, and thats with having a coolant flooding system hosing it down .

-

04-24-2013, 12:52 PM #6Junior Member

- Join Date

- Apr 2013

- Location

- Burlington & Toronto

- Posts

- 20

Thanked: 2

I have Wire EDM machines to use (will cut through the hardest material like butter) and surface grinders with magnetic sine vices that pour coolant on the work. Work hardening won't be an issue. It's also a wedge grind so I'll be able to surface grind it with a magnetic sine vice set up. Made multible dies out of pre hardened tool steel, and I prefer hardening blocks vs profiles for the way it through hardens evenly. I made the die this offcut is from the same way, and it's designed for 1 million cycles shearing .125" stainless. Don't worry, leave the metal work up to me

But yes, working with vanadis this hard by hand would be nearly impossible, as I even have to redress the grinder's wheel every pass. This isn't o1 or even D2 for that matter. This stuff is extremely difficult to work with at this state and not reccomended for beginers. O1, A2, etc is a cake walk compared to this stuff. But, it makes an incredible edge and I hope what I make from it works out well.

Any suggestions for pivot bearings/bushings? Do people normally like a stiffer pivot or something that rolls on it's action fairly smoothly?Last edited by AFisher; 04-24-2013 at 01:01 PM.

For the love of making

-

04-24-2013, 01:18 PM #7Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Would be great to see some pics of the process you will be using.

-

04-24-2013, 01:24 PM #8

A razor's pivot has to do both for the razor to be functional. Try taking apart some vintage blades, and you'll see how it's done. Same goes for all the geometry of the steel, as well. There's a reason they've all looked so similar for so long.

And since you mentioned knives in a previous post, the sooner you can put aside your knife stuff and focus on the idea that this is a razor, the smoother the process will go for you. You can't fill a cup that's already full.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote