Results 1 to 10 of 12

Thread: Temper Colors?

-

05-04-2013, 02:23 PM #1Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072 Temper Colors?

Temper Colors?

I've just hardened and tempered a new file razor, but I'm concerned & confused about the color of the steel after tempering.

The blade was in the toaster oven for 2 x 1 hour cycles at around 395-400 F.

I was expecting a straw/yellow color, but there is definitely shades of blue/purple in there.

It never went over 400F during the tempering. It is however an unknown steel.

It was an old Wilthshire file.

Can anybody shed any light on the coulors here, have I over cooked it?

Thanks

Grant"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

05-04-2013, 02:37 PM #2"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I think you found something important about toaster ovens. They don't have the finest control around a set point.

I see some of the right sort of bronzish in there. Other color oxides appear depending on cleaning chemicals if you wiped down the blade.

Does it still skate a file?“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

The Following User Says Thank You to Mike Blue For This Useful Post:

baldy (05-04-2013)

-

05-04-2013, 02:47 PM #3Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

I hate to admit it but the file does seem to be scratching more than it should.

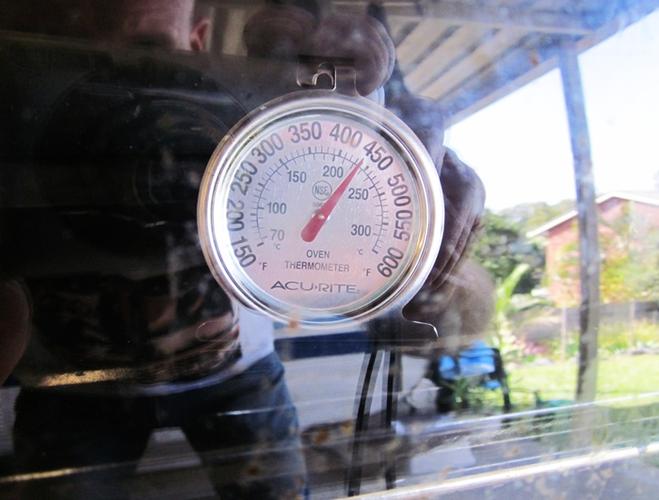

I dont think my temperature was out though. The dial on the toaster oven and the extra thermometer thats in the above picture both said 200 deg C.

Can some steels blue turn at lower temperatures, and if so does the colour still represent the hardness in the same way?Last edited by baldy; 05-04-2013 at 03:11 PM.

"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

05-04-2013, 03:01 PM #4Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

I just went and rubbed this razor and an old broken Fredrick Reynolds razor on a good file and a worn one also.

It's a hard thing to judge, but they seemed similar in hardness.

Obvoiusly If I need to re harden and temper it I will have to do it before grinding.

Wish I had a hardness tester.

I did clean it with dish washing liquid and a scouring pad before putting it in the oven wrapped in foil. Dont know if that would make any difference.

Maybe I should just re do the whole process and temper at a little lower temp.

At least if its too hard to hone after grinding I can always put it back in the oven until I get it right.

GrantLast edited by baldy; 05-04-2013 at 03:07 PM.

"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

05-04-2013, 03:08 PM #5Senior Member

- Join Date

- Jan 2012

- Posts

- 388

Thanked: 51

I'm no expert, but I'd say that it probably needs to be re-hardened. In my limited metallurgical experiences, I've heard that the blue shade usually represents the steel having been spring tempered and will probably be too soft to hold a razor's edge.

-

The Following User Says Thank You to myersn024 For This Useful Post:

baldy (05-04-2013)

-

05-04-2013, 06:32 PM #6

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

baldy (05-04-2013)

-

05-04-2013, 06:32 PM #7

-

The Following User Says Thank You to Bruno For This Useful Post:

baldy (05-04-2013)

-

05-05-2013, 03:38 AM #8Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

Yep, as expected you guys were right.

I figured out the problem though, so thats the main thing.

Just a stupid novice mistake.

I left a tray in the oven with the razor sitting on that, while the thermometer was hanging from that shelf.

The tray essentially made 2 sections to the oven, with the razor in the top section and the thermometer in the bottom. Giving me a false reading

I just turned everything back on just like last night, and the thermometer sat on 400F, I then moved it up to the top shelf where the razor was sitting last night, and sure enough it began to climb. So obviously the top is much hotter than the bottom section.

So when the kids go to bed tonight I'll be firing up the forge again and repeating the whole process. Tempering on a wire rack with the thermometer sitting right next to the blade, like I successfully did it last time.

Would you guys recommend going back to the start of my routine, which is 3 thermal cycles to normalize before the quench?

Thanks guys

GrantLast edited by baldy; 05-05-2013 at 04:07 AM.

"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

05-05-2013, 11:25 AM #9

Although i dont have anything to add here with regard to metalurgy, I just wanted to tell you how much i like your razor here.

Great shape Grant !

I started a file razor well over a year ago and kinda dropped it so I'm really interested in how this gets done.

Thanks for posting.

Mike

-

The Following User Says Thank You to Mcbladescar For This Useful Post:

baldy (05-05-2013)

-

05-05-2013, 02:27 PM #10aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Good show Grant, I look forward to seeing it finished. That point would scare the crap out of me after I tried to take my ear off the other day with a simple spike! It shows that you took your time on it.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

baldy (05-05-2013)

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote