Results 21 to 29 of 29

Thread: Unexpected Hamon

-

05-24-2013, 11:30 PM #21

I wouldn't be supriced if it was the jnats that made the Japanese make their good blades.

As they could see what happened when hardening and then they started to play with different steels and techniques.Hur Svenska stålet biter kom låt oss pröfva på.

-

05-25-2013, 12:51 AM #22

I am not sure that it matters, but, spine down or up should result in nearly the

same hardness result on the thin blade. Hardness is not the only issue.

As the parts of the razor are quenched they change dimensions diferentially

and on a big sword will curve. The edge should be in slight tension.... without

tension it might potato chip warp. Too much and it will crack... If the blade looks

correct and not warped then you did it correct (simple answer).

As for hamon without a clay line... The back of the razor has steel much thicker

than the cutting edge. Heat will stay in the thicker steel for a while then migrate

from the thicker spine toward the thinner edge after it comes out of the quench.

Depending on the grind and quench timing the heat might move out enough to be seen

after polishing and etching. The differential might vanish with later annealing.

If the file pattern is still sharp enough to worry hones a single layer of tape should solve that.

It looks like the tops are flat enough though. Clay, molten lead, molten salts, oils, argon are used by

some to keep the carbon from burning off... The magic of modern hones will prove of value if the steel is very hard.

Beautiful work. If the heat treatment is right it should hone shave very well.

Enjoy...

-

The Following User Says Thank You to niftyshaving For This Useful Post:

baldy (05-25-2013)

-

05-25-2013, 06:52 AM #23

Not sure I agree. If you quench spine down, the edge will touch boiling water / steam when going down, because the water (or oil) has been pre-heated by the spine. Especially if you hesitate when going in. That could lead to uneven hardening. This is a risk, not a certainty. I've done a bit of experimenting with hardening lines on kitchen knives, and I've seen this happen sometimes, when my quenching motion was hesitant.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

05-26-2013, 03:03 AM #24Lookin like a crim

- Join Date

- Apr 2009

- Location

- Coffs Harbour Australia, Home of the Big Banana

- Posts

- 2,706

Thanked: 1072

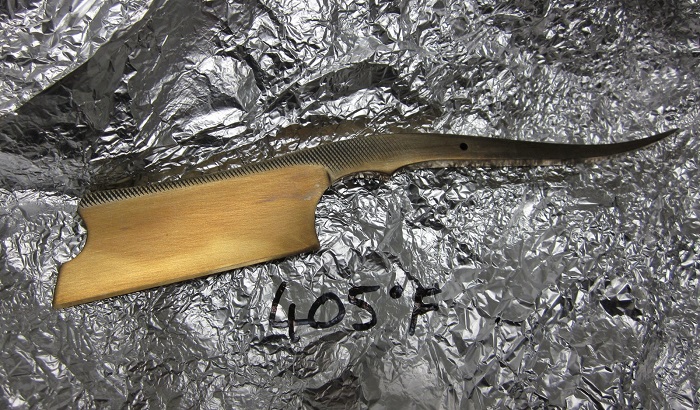

Here's a couple of better pics after re-tempering last night.

Hopefully you can see the Hamon I'm talking about

This was sanded to 320 grit before going into the oven.

It's still pretty hard actually. I might end up putting it back in for another hour at 420 F if I'm still struggling to get a bevel set.

Grant"I aint like that no more...my wife, she cured me of drinking and wickedness"

Clint Eastwood as William Munny in Unforgiven

-

05-26-2013, 06:47 AM #25"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Nice colors. Looks like the hardening line drops off by the heel. It will be worth observing if there is a detectable resistance chance on the hones there. Hamon are funny things, they can go places you don't want just as easily as not going places you did want.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Catrentshaving (05-26-2013)

-

05-27-2013, 04:02 AM #26aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Wish I lived close to you Grant, I've got the stones to work on it...we are just a few miles away from one another. That blade is a great looking blade and yes, I can see the hamon well. This just ads to the character and beauty of it. You have a good eye my friend and I always enjoy looking at your ventures.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

baldy (06-04-2013)

-

06-02-2013, 03:50 AM #27

A suggestion maybe, there is something that has been added to the file steel when it was made. Being that file metal is a pretty good material from the manufacturer would there possibly be an ingredient that was added at the time of manufacturing that is unique to that manufacturer. Like grandmas cheese cake recipe. It was great but nobody could duplicate it. But that material is showing up because of the way the quenching is done. Like spine down is cooling faster and driving that material up to the finished end. Just a thought. In 30+ years of machining and welding I have seen metal changes in color and looks that nobody had an answer for. Go figure. Good luck grant.

-

06-04-2013, 03:20 AM #28

Walleyeman may be onto something. A file needs to be hard as heck yet not fragile. I would not

exclude tricks putting harder steel on the surfaces and also case hardening.. In this case my bet is

on heat in the thicker spine not reheating thinner steel of the blade area. This differential quenching

trick is interesting. Way back I was taught that hammers were sometimes quenched by a gentle stream

of quenching oil in the center of the face. The rest of the hammer face was cooled a lot slower so it

would not chip.

In the end it is the shave test that tells all. The rest can be a secret....

-

06-04-2013, 05:57 PM #29"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Old files, from reputable brand names, are more likely to be good steel all the way through.

Since the 1980's there have been reports of files being case-hardened mild steel because manufacturing costs are lower and no one is in the business of resharpening used files to any great degree. They have become consumable items, used and scrapped.

The problem with heat treating a case hardened file is that the skin of hardenable material is very thin (thousandths thin) and that carbon added to the surface of a file will dissolve into solution at the hardening temperature and average itself throughout the bar. In the case of someone who is doing forging, this takes only three to four heats. While the carbon content might be 1.00% at the thousandths thick stage, it will be significantly less so when averaged against the mass of the file itself.

Someone who grinds a razor from a case hardened file, will remove the case hardened layer by the time they get to a razor shape and it won't harden anyway. There would be no hamon at all unless the parent steel was sufficient in enough carbon to harden on its own.

It is technically possible to add or subtract carbon from a steel bar by placement in the column of fire in the forge. I would not eliminate this as an accidental or intentional possibility but Baldy will have to share his forging methods. If he's of the school of "stick it in the fire, get it hot and hammer," then it could be accidental but the odds are that he will burn out more than he adds to the steel. Intentional addition of carbon from a coal or charcoal fire implies a better than average intent (experience).

QED: this file is hardenable and no special tricks were done to make it so. And, yes, weird things happen with steel, which makes it so much fun to play with.

-

The Following User Says Thank You to Mike Blue For This Useful Post:

niftyshaving (06-08-2013)

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote