Results 1 to 10 of 18

Thread: Suehiro Staining

-

07-29-2013, 04:00 PM #1

Suehiro Staining

Suehiro Staining

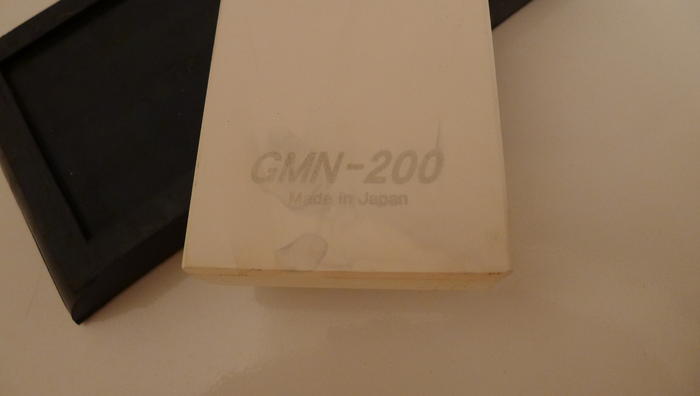

My stone came with black staining on the back side from sitting in the rubber base during shipping. Perhaps from the heat, I don't know. I'm not sure if this will affect honing. The staining could be rubber? The vendor and Suehiro say "probaby not" but I don't think they're 100% sure. They say because it's for razors, I may feel it. From now on, All Suehiro 20k's will be wrapped in plastic before shipping. Did anyone else have this?

I wanted to keep the logo side pristine, so I left it. Now, I'm wondering if I should lap the top side and use it instead. BTW, Stu is a great guy, and will work with me. I want know what you guys have found. My stone can't be the only one that has black stains that cannot be removed.

Would you ask for a replacement stone?

BTW, All my razors are finished up to a Nakayama Asagi, so I have nothing to hone at the moment to test it.

Keep in mind, we're dealing with a very fine 20k finisher. (The stone looks worse in real life..)Last edited by zib; 07-30-2013 at 04:18 PM.

We have assumed control !

-

07-29-2013, 04:20 PM #2

Mine has some of that on the label side. I guess from sitting in the black rubber holder. Some of the dye leached into the white stone. Kind of light gray like yours is. Doesn't hurt anything. Now when I finish honing I don't leave it sit in the holder wet. If what we are talking about is the same thing, I wouldn't ask for a return. Like I say, mine is on the label side and I don't hone on that side, I couldn't imagine it would effect the honing though.

-

07-29-2013, 04:27 PM #3

Thanks Jimmy,

I'm sure they're are other's out there. I'm curious. I'm off this Wednesday, and will hone a blade up to 12k, then to the Suehiro 20k to test it.We have assumed control !

-

07-29-2013, 05:07 PM #4I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Rich knows mine was fine as far as staining.

I ditched the base long ago, the common adjustable base is more comfortable to use imo.Stefan

-

07-29-2013, 05:41 PM #5

Mine arrived Friday. It was stuck to the rubber base well enough that I stopped and wondered if it was supposed to be that way. Decided not and separated it. The bottom of the stone was tacky, as was the rubber base. I also decided to preserve the stamp, so I lapped the bottom, tacky side, with an Atoma 400. The stone was crowned a little in the middle. Took about 10 minutes to lap with pretty light pressure. Tackiness is gone and there was no staining, even initially. Works excellent!! The rubber base.....I'm going to try soaking it in water with dish washing liquid. Try to find some use for it, but I'll use the G20 on the steelex holder.

-

07-30-2013, 11:48 AM #6

The oils in the rubber/thermoplastic may cross link with the surface of the hone. You can try lapping it out but that depends on how deep the oils penetrated the surface. The surface migration of extender oil in EPDM vulcanizates - Zinbo - 2003 - Journal of Applied Polymer Science - Wiley Online Library

Migration of Processing Oils of Thermoplastic Rubber Treated with RF Plasma - Springer

Mike

-

07-30-2013, 12:10 PM #7

Here is one reason i love this forum, a quote like this from the reference posted by Modine:

Extender oil bloomed on the surface of ethylene–propylene–diene rubber (EPDM) vulcanizates has been analyzed by a dissolution/size exclusion chromatographic (SEC) method.

To the other end of the spectrum with something like: 'my razor won't shave what am I doing wrong?' Pretty fun diversion."Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

07-30-2013, 12:14 PM #8

-

07-30-2013, 12:51 PM #9

The reason the coloration is black or gray is because some of the pigment in the rubber/thermoplastic leached out into the oil. Carbon black is the pigment used as filler in compounding rubber/thermoplastics. Do you want carbon black on your ultra-fine finishing hone?

Mike

-

07-30-2013, 01:24 PM #10

Mike, do you reckon it could do any damage ? Chemical reaction with the binder or the abrasive ? If it is just cosmetic I don't have a problem with it. Inquiring minds and all of that. Here is the staining on mine. Looks kind of like fingerprints but it is probably the same as Rich's hone, from the rubber base.

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote