Results 21 to 30 of 42

Thread: Agate / Greenstone?

-

11-25-2013, 09:27 PM #21Senior Member

- Join Date

- Nov 2013

- Posts

- 101

Thanked: 4 I used my tiny 50/10m stone like this last night for a final polish on the edge of a utility knife; started on a dragon tongue with slurry, moved on to a yellow lake with slurry, then to the purple welsh stone with oil and finished by doing circles on the green stone both dry and with oil. Then I used chalk-pasted canvas, newspaper and kangaroo hide to strop.I have *not* used it on a razor, but originally got it out of curiosity for carving tools and chisels.

I used my tiny 50/10m stone like this last night for a final polish on the edge of a utility knife; started on a dragon tongue with slurry, moved on to a yellow lake with slurry, then to the purple welsh stone with oil and finished by doing circles on the green stone both dry and with oil. Then I used chalk-pasted canvas, newspaper and kangaroo hide to strop.I have *not* used it on a razor, but originally got it out of curiosity for carving tools and chisels.

I can't say how much of it was the green stone, but it's damned sharp now. I've also used the same stone to refresh the edges on kitchen knives (not using other stones) and it does work. It won't sharpen a dull knife, but if a knife has lost a little it can put the bite back in it rather like a strop does. When I use it though I don't really use it to hone, but to polish and straighten; either running it directly along the blade, back and forth or doing quick circles. Without oil you'll get some metal dust so I know it cuts better dry. With oil it just polishes and I get almost no dust.

I use a lot of pressure, and would use more but the stone I have is so small using it with too much pressure would likely result in me cutting myself open. Hence my interest in the larger stone, and my thought of using it as a kind of post-finish polisher. I'm very curious about trying it with slurry and water (if it works on a transluscent arky there's no reason it shouldn't on these) I think a fine diamond file would be good for getting some. I also want to try the polisher he has which is listed as 6k as it might move more metal.

If nothing else I can use it with slurry from other stones, or various pastes/polishes for a final finish. I have no fear of it getting plugged up because it's so glassy.

-

12-05-2013, 04:26 PM #22Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

I think I'll do up my next razor after the japanese hone on my agate. It's quite possible that the fact that it almost doesn't cut may make it burnish an edge and make for a comfortable shave - maybe I'm discounting it too much just because it seems useless for tools. For tools, it might even be useful as a strop, or as you described, putting an edge back like you'd do with a steel.

And, as you mention, it should be a good base for slurry (I don't know if I said that, I probably didn't) since the underlying hone doesn't do much.

If anyone is thinking of getting it to replace a finisher, I wouldn't do that, though. If anything, it'll be like an after-finisher refiner stone.

I still haven't yet tried a slab of jasper, which is something very cheap that is extremely fine, and on water can do the same thing (burnish), but cut quite fast with slurry.

-

12-09-2013, 04:37 AM #23Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

OK, I Might have to revise my opinion of this stone somewhat. Tonight, I used the agate as a burr chaser after a washita stone (this is on tools, I still haven't used it on razors). It is uncanny how slow it's cutting. It brings the back of my chisel to a super bright polish, but it cuts so slowly that if I have any other grooves in the back of the chisel that I couldn't see previously, they present themselves.

With the "already sharp edge" coming off of a washita that is very well settled in (think translucent arkansas for about how sharp this washita makes a chisel), and a LOT of pressure on the chisel edge and back, I get an edge that is sharper than any arkansas stone I've ever used.

That leads me to consider two things:

1) the kind of pressure I used isn't acceptable for a razor, not even a tenth of it.

2) even if I can't use that pressure, it's possible that this could be a good smoothing of the edge following another very fine stone like a chinese stone.

I'll see next time I hone what it does as a follow-up to the razor.

It definitely does not care for steel that's alloyed much. I used a chisel that's not as hard as a razor and that is very plain steel.

I found this out because I was going to toss 1 micron diamonds on it and use it as a strop for tools. Now I won't be doing that, it's got some potential to chase burrs on paring chisels and leave an edge that is rivaled by the best natural edges I've seen.

-

12-14-2013, 07:03 AM #24

Hi Guys,

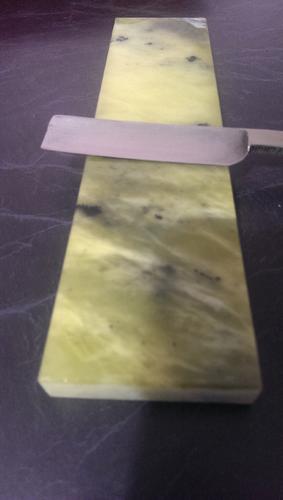

I received the green stone a few weeks ago although due to moving into a new house it took a while to do some testing.

The stone is softer then what i was expecting, softer then a Translucent Arkansans but harder then a slate. So lapping was much easier then i was expecting.

I lapped the stone with my DMT lapping plate and I polished the scratches out with a well worn 325dmt. The 325 DMT creates a light slurry only after a 5 or so lapps (As i said, much softer then a translucent Arkansas)

I first tested the stone with water, it almost cuts and may be the better option for this stone although some more testing is required. After testing with water i finished a razor on a 12k Naniwa SS and then moved to the green stone with WD40 on the stone and even WD40 seems to be too thick, the blade feels like it glides over the stone rather then against the hone... It's more like buffing on a piece of glass then honing.

The razor turned out surprisingly smooth, it seemed to have improved the Naniwa 12K and i shaved directly off the stone. No stropping.

I still need to do more testing and probably need to test it on another few more razors before i can conclusively determine its performance.. Although this 'may' be a nice hone for touch-ups.. After more testing ill know for sure.

Slurry from the 325 DMT

Blade against the stone for size

factory cut marks from the side

Torch behind the stone to show how translucent it actually is

Last edited by Brighty83; 12-15-2013 at 05:44 AM.

Chris.

-

-

12-15-2013, 03:38 AM #25Senior Member

- Join Date

- Nov 2013

- Posts

- 101

Thanked: 4

Great review, some interesting finds there. I'm going to pick one up myself and see how it works.

-

12-15-2013, 05:42 AM #26

I don't think this will be a stone anyone will pull out often if at all after a few weeks of testing, if they even last that long with it.

I found a second razor that needed the bevel reset. So i went though my set of Shapton M5 stones and finished on the 12K. I don't really like the feel off the 12k so i went to the Green stone with a lather this time. Again there did seem to be an improvement. The lather seemed to give the right balance of slip. The WD40 seems to thick and water seems to thin.

When i find a couple more razors that require honing ill give it another go although I cant see me using this stone much after a few more tests, its just too slow and the results at the moment aren't anywhere as good as i can achieve on some of my other finishing stones.

I would love one of the Arkansas guru's to have a go with this and see what they think.Last edited by Brighty83; 12-15-2013 at 05:49 AM.

Chris.

-

12-15-2013, 06:27 AM #2750 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

I am thinking that if I had a stone like this, I would try it with a slurry of aluminum oxide ( Linde "Ä") OR Iron Oxide .3 micron.

Does the stone feel anything like a Spyderco UF?JERRY

OOOPS! Pass the styptic please.

-

12-15-2013, 07:18 AM #28

-

12-15-2013, 08:11 AM #29

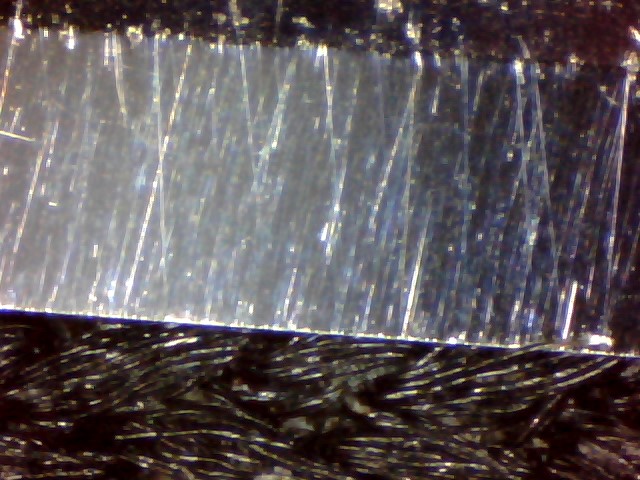

A few pics of the bevel from the stone. The cloth in the background is my mouse pad lol

Chris.

-

12-15-2013, 08:19 AM #30

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote