Results 11 to 20 of 25

-

06-08-2014, 07:30 PM #11Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Dennert is the maker of the white handled razor. The razor that I'm testing, though, is a razor branded "es-ese", which I've never heard of, but it's a relatively nice razor.

I'm not quite sure, actually, why that (novaculite) stone is as scratchy as it is in the photo. I loaned it to someone who wanted to try it out (to see if he wanted to buy one) and he may have lapped it, though he claimed he didn't. Still, the edge appears to be decent quality.

In terms of recommendations, I'd still stick with a japanese stone as a first natural finisher, though on the less collectible side and from a dealer with a decent reputation. I've seen a lot of stones that are very plain looking for $500, etc, and there's a knife dealer in the states selling what would've otherwise been cast-aside stones (very soft type stones) for several hundred dollars each. I guess there is demand.

I don't think the jasper is a bad way to go, though, but it has to be biggs or owyhee. I've got two of each, and all four stones are about the same level of fineness. The two owyhee jaspers I have are more similar than any other pair of natural stones that I have (bought at different times from different sellers), and same for the two biggs.

Pictures aside, from the shave, it is a decent razor hone. Slabs can sometimes be had on straight up auction for a dollar or two dollars, at the most from a scrupulous buyer, $15 or so. They are not a beginner hone, you are correct. They need to be prepared, too - none come in geometrically desirable bricks.Last edited by DaveW; 06-08-2014 at 08:01 PM.

-

06-09-2014, 11:48 AM #12Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Edited my prior post to comment on the shave from the novaculite. There are two things I'm going to do again when done with the chinese hone, and the first is to go through my novaculite stones and find one that I know I haven't loaned out (and know thus that it's completely broken in) - I should get a shave that's closer to the japanese stone and jasper, and the shave this morning was acceptable, but not like the shaves on the japanese and jasper were. At this point, all three shaves were keener than any razor that I've ever gotten "shave ready", but shave ready doesn't necessarily mean sharp.

Pictures of the chinese stone honed razor will come tonight or tomorrow after I hone it.

I'll redo the jasper again later, too, and see if the same anomalies happen at the edge, and if they do, try to get a 45 degree shot with the microscope I'm using.

-

06-09-2014, 02:41 PM #13Senior Member

- Join Date

- Apr 2014

- Location

- Yorkshire , England

- Posts

- 356

Thanked: 44

I have puzzled over the use of natural stones over synthetic stones for some time. I just struggle to grasp why someone would use something that firstly may be a dud and why would you not just buy something you know will work and you know exactly what grit size you are getting.........BUT people sware by the feel of the edge they get off these natural stones so there must be something in it.

Looking at those edge images and images in general of edges off natural stones, they all seem to have the occasional deeper scratch here and there and that got me thinking. The Japanese sushi chef's have a term "the blade is running". It happens when the knife edge gets too polished and instead of slicing into the fish it scates over the flesh instead of slicing in so in this scenario extremely small micro chips are actually desirable.

Now I know razors are not knives and that they are essentially push cutters and not slicing tools but there is some slicing motion going on.

What I am thinking is that these natural stones are kicking out the odd particle that is bigger than the rest which causes small micro chips in the blade edge. The extent of these rogue particles is the difference between a good stone and a bad stone from the same stock. I am thinking that these occasional microchips are helping with the shave by catching hairs before the rest of the blade cuts it. This effect would not happen on a synthetic stone.

What are your thoughts on this ?

-

06-09-2014, 02:59 PM #14Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

The biggest reason I use natural stones is because of how sparing they are with a razor, and once you get a good one and get used to it, it's a single self contained unit that doesn't change geometry of a blade or have pigment powders or little diamond powders everywhere. For some reason, they are right at about the right sharpness for me to get easy hair removal, but to not get anything like weepers (which I will get if i do something nutty, like use 0.1 micron iron oxide powder).

Because of woodworking, I've tried just about everything, and I do use synthetics generally on a new-to-me razor, though a natural progression starting with a washita stone is very fast for anything other than mass material removal.

It's my opinion that the grooves are shallower from a natural stone, any of the type discussed in this thread, and shallower grooves make for a more comfortable edge at a given level of sharpness. I don't know if that's really true or not, but it sounds good.

Anyway, the other benefit is the ozaki stone first used in this thread has been in my cabinet for a couple of years. It will work for a lifetime. 5 minutes use at most once every 3 to 6 months. it works the same way every time. I've got a whole bunch of stones, but after this test, and for every razor that I ever get that's dialed in, it'll just get maintained on that stone.

I don't think an edge can be too uniformly perfect, so I'm not sure the desire for a tiny bit of tooth on a meat knife can be cross referenced. In reality, I think that the scratches that look deep are still fairly small scratches (invisible to the naked eye and then some) and plenty sharp enough to cut hair easily, so they're not noticed. Some of them terminate or nearly terminate before reaching the edge, too.

And one final reason, I get an edge a little less keen with a sigma power 13k, shapton 15k, .... (the only stone I haven't tried is the gokumyo 20k, which may better the ozaki stone), and the linen and leather to me are more vital than a particular stone.

(I don't expect anyone else to share my opinions, btw. Ultimately, you can get any shaving acceptable stone to make a shaving acceptable edge, and to some extent - especially with naturals - success is a matter of familiarity).Last edited by DaveW; 06-09-2014 at 05:20 PM.

-

06-10-2014, 12:44 AM #15Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

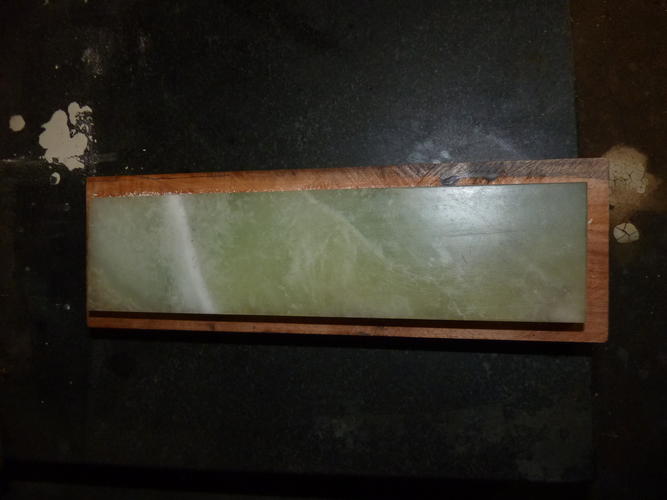

Chinese hone - looks like this. I have no real love from this hone. It has fairly large particles and once it's broken in it goes to super slow cutting that makes the most broken in jasper or novaculite look like diamonds. It just has a rubbery feel, but every once in a while a particle makes its way loose onto the surface and you get the grain of sand sound. Whether the damage on the edge is because of that or not, I don't know.

If I used this stone for 100 razors, maybe it would settle in to the point that it released no particles, but woe be to the person who lapped it again because it would start all over. I flushed the surface of the stone with WD 40 and then wiped it off 4 times, did 200 laps (125 with wd 40 and 75 with mineral oil), generally wiping the stone additionally every 50 laps or so to make sure nothing foreign was on the surface.

Hanging hair test, it's less keen than the novaculite, which was less keen this morning than the jasper and the ozaki hone were.

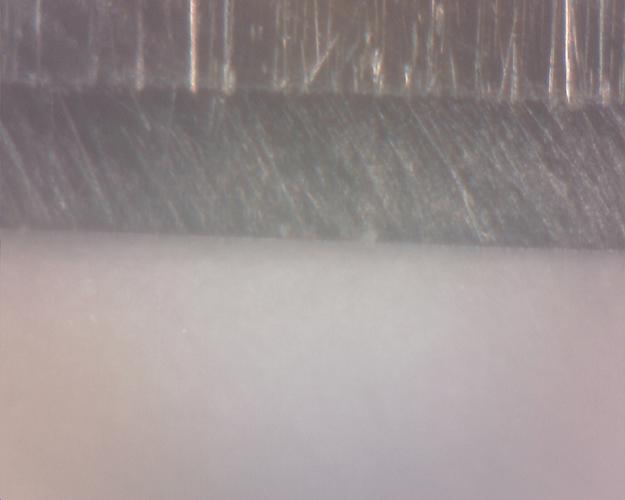

The camera didn't know what to make of the hazy finish and it was searching for the right light level, and ended up on light picture. Not sure if the dings on the edge are the stone in general or if they're the random here and there loose particle.

The original point of this thread was in response to someone who asked about getting a small one of these for razor touch ups, and I said don't do it. If you're hard up to try a natural stone and you only have ten or twenty bucks, get a piece of owyhee jasper in a reasonably large size and sand over the edges, or more appropriately, belt sand an edge straight or diamond hone it straight.

I don't really want to shave off of this edge with no linen, but i'll do it in the name of (kind of sort of but not really) science tomorrow.

EDIT: to my complete surprise, the razor provided a very comfortable and smooth shave after stropping it. I'm not sure why experience doesn't match the pictures, but it doesn't. As slow as this hone is, I'll give the razor another 200 laps tonight and see if the chipped edge improves or gets worse, but the edge itself is in an entirely acceptable condition when it comes to the shave, and I can't imagine it wouldn't be even better coming off of the linen and leather instead of just leather. Grading the shaves, the japanese edge was the best, the jasper and this green stone are similar, and the novaculite was OK but a little less keen. I'll re-do the novaculite.

I still wouldn't recommend buying one of these green stones, though, they are way too coarse on slurry and once the slurry is gone and they break in, they are *painfully* slow. The slowest stone I have ever used by far, and I have had four chinese guangxi stones and some ozukus so hard they hardly seem to cut.Last edited by DaveW; 06-10-2014 at 12:39 PM.

-

06-10-2014, 12:52 AM #16Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

You might be thinking the chinese green hone doesn't look like the deep green ones on the alibaba ads. Me, too. I think they're a little bit like fast food - they look better in the ad copy than they look when you get them.

By the way, cost of this stone, $85.

(and to repeat, this is a big one - 200x50x25. Don't buy a small one. It might be cheaper, but it'll be even less useful).

I guess you can tell I ruined my chances of selling this stone in the classifieds, but that's OK. I don't need people cursing me when they use stuff I sold off.Last edited by DaveW; 06-10-2014 at 01:34 AM.

-

06-11-2014, 12:02 AM #17Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Switch of plan - jasper again, 200 laps, but this time with a drop of dish soap on the surface and then watered. Strangely, the stone scratched fairly uniformly, I guess because of the reduction in surface tension, who knows.

Again, the microscope is confused. Sorry for the light colored picture. This time, a little bit more tooth to the edge due to the cutting of the stone, but no dings like the first picture. Presume the stone is nearly done releasing particles. As I hone, I can see the stone still has some areas that could be lapped out, so there is more fineness available on this stone, but I don't want to lap it again and create a world of damaging sharp particles. Plus, once I'm done with this experiment, I won't be honing a razor for a long time, anyway.

At any rate, here's the picture. We'll see how the shave is tomorrow. Again, surprise from how easy the shave was from the chinese hone this morning, despite the look of the edge. I thought it would be horrible and I was exactly wrong. All of these shaves have been in the same ballpark except for the novaculite, but we'll solve that in the next few days.

-

06-11-2014, 01:12 AM #18

The "es-ex" should be very nice. After all it was made by C.F. Ern.

The flourish on the "x" does look like "se" but you should see an X over an S on other parts of the logo.

Good thread. I can see some of the chippiness that Euclid440 mentions in the initial pics but IME that may not be an issue for the shave. Most recent looks very improved.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

DaveW (06-11-2014)

-

06-11-2014, 02:11 AM #19Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Yes, visually it's definitely there in the pictures, but not the last one. A brand new jasper has a funny grippy feel from time to time, and I don't know if that's particles that aren't yet broken in (not free particles, but areas of the stone where they're fixed), or if the damage is caused by loose particles, or if it's just caused by the stone itself because it's not ideal.

This last session is still only the third razor this stone has seen since being lapped new. If I had any real fear about it, it would be that when it breaks in it will totally stop cutting, and as euclid440 mentioned, most of this stuff probably isn't very good for beginners. It may be that none of the stones here are, they're slow, and require a little bit of judgement.

Since the jasper is on water (my other owyee slab is on oil, and used for tools, but it could be cleaned off and tried), I may try it with a routing using a good quality tomonagura to speed it up a little and then follow that with a dilution like a japanese stone.

To me, having already spent the money, I definitely like a good japanese stone. It would be wonderful if someone would find these jaspers in large pieces and sell them cheaply in a hone shape, but that's not likely to happen - they'd just end up costing $100 or so for someone to go to the effort to find large bench stone sized pieces and then cut and polish the surface and then chamfer. The big slabs for $10 + shipping make for cheap experimentation.

I know I already mentioned it, but the engraver/jeweler/professional stone cutter who turned me on to biggs jasper swore by the true jaspers for use on engraving tools, each is apparently a little different (though the biggs and owyhee are both fine cutters with sharp particles), and some are not uniformly dense but somewhat porous.

Bottom line with all of these is that they will hold onto their particles and can be worn in and used with good effect with some experience. We talk a lot about the details online, and it drives us a little nutty trying to explain things that are subtle, easy and unspoken with some experience.

Thanks for letting me know who made my razor, btw. I was a little miffed at having spent $60 on it when I got it, but it's turned out to be a really lovely shaver and it likes the natural stones.

-

06-11-2014, 04:03 AM #20

Two things,

1. The simplest way to observe the relative density of areas in a piece jasper is to wet the stone evenly with water. The density of various sections will will be visibly observable by where water is absorbed first. The last areas to absorb water are the densest.

2. The fastest way to break in a hard hone is to burnish it with another hard stone. I do this with barber hones, arkys, ect.

Carry on.

JonathanSHHHH!!!! It's "respect for the age of the blade", NOT laziness! - JimR

- JimR

-

The Following User Says Thank You to Datsots For This Useful Post:

Blistersteel (07-15-2014)

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote