Results 1 to 10 of 25

-

06-07-2014, 02:18 PM #1Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458 Natural Stones: Japanese vs. Jasper vs. Novaculite vs. Chinese Agate/Faux Jade?

Natural Stones: Japanese vs. Jasper vs. Novaculite vs. Chinese Agate/Faux Jade?

Spin off from another thread where the chinese jade was asked about. I'll re-put the Japanese stone stuff in here (that I put in another thread). My original intention is to point out that if someone is being thrifty, biggs or owyhee jasper is a better rock to consider than the chinese green hones on ebay.

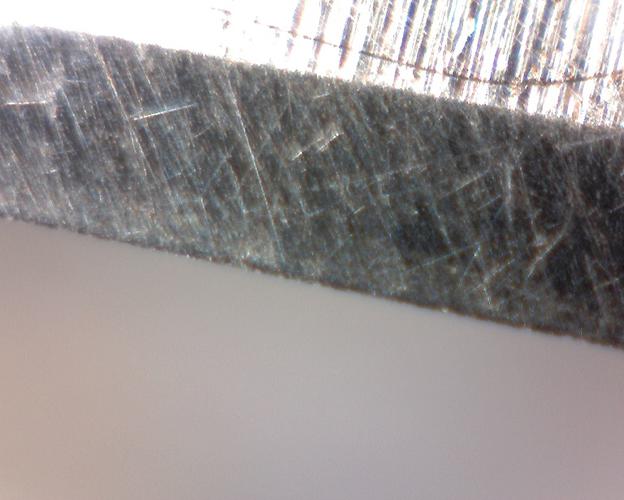

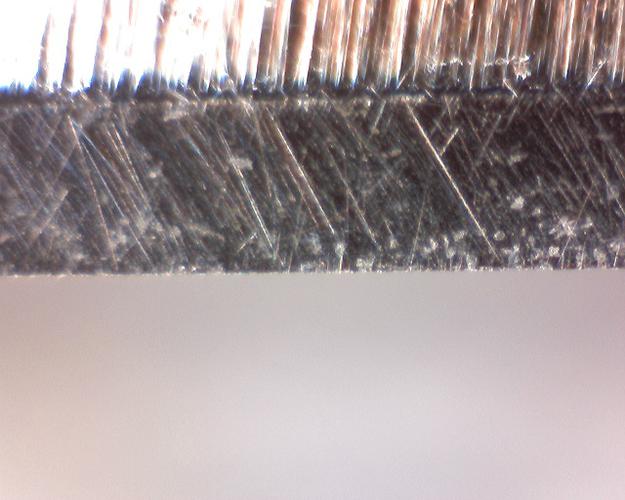

First stone - vintage ozaki mine barber hone, the microscope says it's at 200x, and I don't think I believe that. It is very close up, though.

200 strokes total, 150 of those on clear water. This hone never sees a DMT or anything of the sort - it is never lapped or flattened after it was initially, and tomonagura for slurry is a fine shoubu or ohira stone. This stone does best on clear water and lots of strokes.

Pictures are same edge, just light angle depending.

Shave was excellent. Really excellent. The edge with this many laps on clear water is very similar in sharpness to chromium oxide powder, no weepers, though. Can't ask for more from any natural stone (this one is my best, despite many that are prettier).

Here is the stone, courtesy of a request I made to alex gilmore years ago where I requested all of the money to be spent on effect and none on looks. You can see your reflection on the surface of this stone, as it should be on any good finish hone that never gets lapped, but it still has enough cutting power to polish an edge.

Cost of the stone: $165

Last edited by DaveW; 06-07-2014 at 02:30 PM.

-

-

06-07-2014, 02:25 PM #2Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

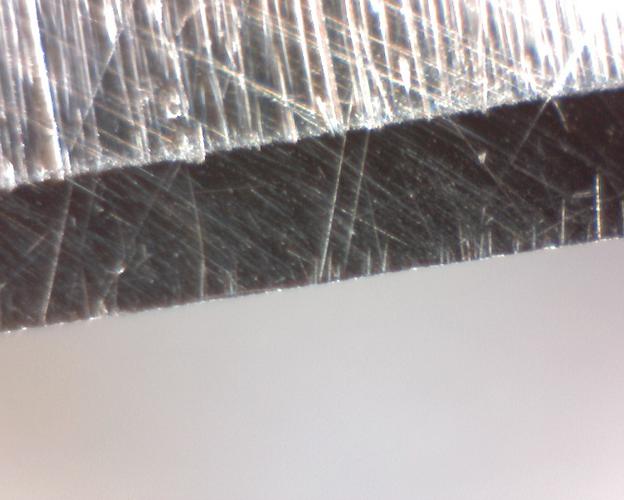

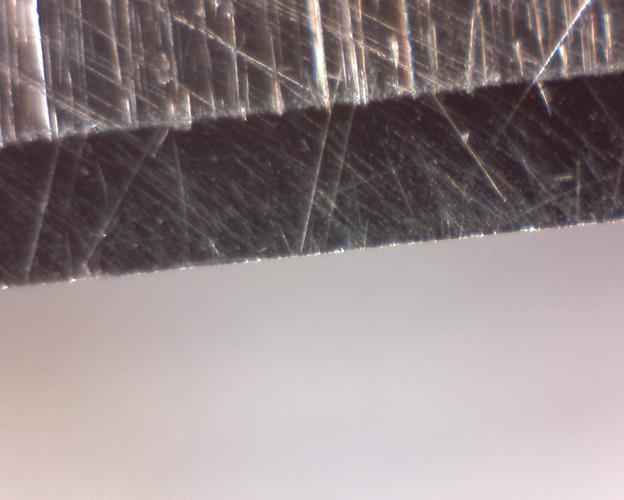

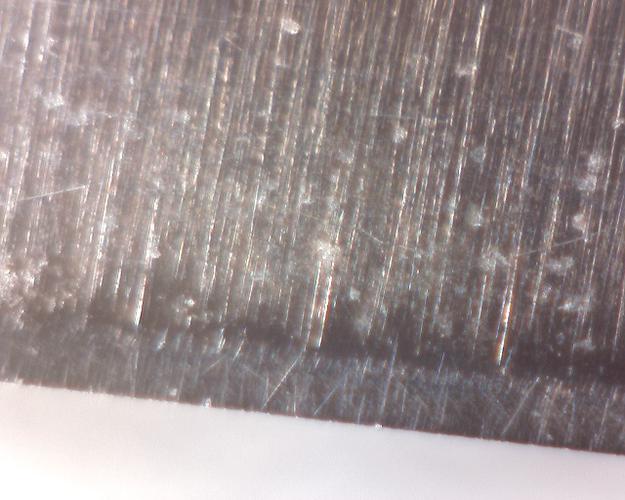

Here are two similar edge photos from the jasper this morning. 200 laps on the jasper after this shave, no leather on the jasper yet at this point.

First hundred laps with moderate pressure for a finisher and last 100 with very light pressure.

Bright polish to the naked eye again, mirror with no view of scratches. Close up, less aggressive scratches than the japanese stone in general, more of a polish, but some stray scratches here and there.

Didn't shave with it yet, will report back tomorrow. Before seeing any leather, though, the edge catches and severs a hair, which for me signals a likely good shave. If I can't get a hair to catch on a razor (my hair, my test), then the shave is usually dull feeling. If it's just barely catching after stropping, still usually represents a dull feeling shave.

And the slab of jasper that did it. no slurry on a jasper in my experience. The particles are sharp and slurry is overly strong like it is on a novaculite stone, though it's not as damaging as novaculite. I haven't tried japanese tomonagura.

Cost $16 including shipping. I had to form the smooth edge on the right side with a diamond hone. If buying a jasper slab, three things are the most important to me:

1) known type (this is owyhee)

2) flat and polished

3) big with an edge that will be easy to lap into a smooth edge that can be chamfered. Neither of those are necessarily common. You want something thin that can be mounted, because cleaning the edge of a bigger thick stone might be difficult, jasper is very hard.

After the shave tomorrow, I will prepare the edge with the green chinese stone.Last edited by DaveW; 06-07-2014 at 02:41 PM.

-

-

06-07-2014, 02:58 PM #3Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The degree of Polish of the bevel is not in and of itself, an indicator of a finishing stone. It is a byproduct of a fine stone that can produce a straight, fine edge by producing fine even stria.

The photos of the razor from the Jnat show a much straighter edge, than the photos of the Jasper stone which show a much more chippier edge.

While the jasper may be capable of polishing the bevel, it may be inconsistent in grit purity or grit size causing chipping in the edge.

It would be interesting to see photos of both edges.

It is the edge that matters, not the bevel. You can polish a bevel with rubbing and polishing compounds on a strop to a mirror polish, but it will not yield a comfortable edge and shave.

If cost is the only issue, film is the most consistent, best value.

-

06-07-2014, 06:25 PM #4Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

Right, I understand all of these things, of course like anyone else would. However, I think you're jumping to conclusions about the jasper's edge, and the other hones might or might not illuminate that.

The edge shown hasn't been stropped, and will look cleaner once it is stropped. I've also shaved off of this jasper once, and this is the second razor it's honed, so in time it will settle in.

As for bang for the buck, are we talking about restoring a few razors, or maintaining a record for decades? A quarter inch of jasper is a lifetime's worth of hone. I've never used a honing film that had the feel of a stone (be it aluminum oxide, chromium oxide or diamond honing films), and while the jasper is a bit more skippy than a smooth feeling japanese hone or an escher, it has decent feel with water or a light cutting fluid type of oil base. In maintenance of a shaving razor (where honing is every couple of months, perhaps as infrequent as once every 6 months for an experienced user), the jasper would win out over the honing films on vintage razors that were made of the plainer carbon steels (which are probably not used by modern makers because they take more skill to grind and have a higher tendency to warp or crack).

Cost isn't so much an issue for me, and shaving isn't what brought me to jasper (carving tools and chisels and planes did) - I have spent about $10k on various stones over the years between woodworking and shaving, i'm just interested in the actual shave experience, especially as it pertains to an experienced shaver who never will bring their razor to anything more coarse than diluted tomonagura.

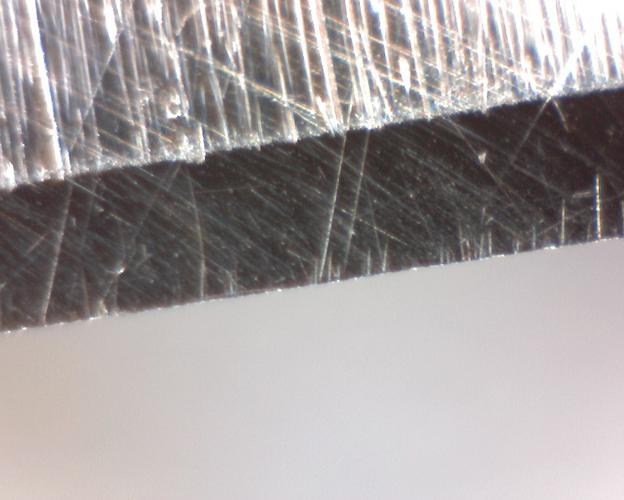

Anyway, I'd wait for the additional data before coming to a conclusion, stones that polish more than cut (including novaculite) often make wire edges and all sorts of bits on the edge of steel that are held very weakly, only to leave a smooth edge once it's stropped off. What's shown in the jasper picture would be easily removed by a vintage linen. Half of my razors have significant spinework, so I don't generally use any pastes or powders.

Can you explain what you mean by photos of both edges, do you mean the opposite side of the bevel?

-

06-07-2014, 07:07 PM #5Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

Here is the jasper edge stropped. It appears about the same.

And just as a side bit of information, here is a japanese razor that I have that just refuses to get as sharp as I'd like a razor to be to shave. It actually looks better on the edge, maybe than both razors, but the bevel doesn't look as good. I don't remember what I honed it with last, probably a less fine japanese stone than what was used in this thread. I've given it several hundred laps on the hone in this thread (the japanese hone) and it just has a ceiling that isn't that great.

I don't know why it refuses to shave. I thought it was overhard at first, and nearly threw it in the can, but before I did, I tempered it to medium straw, which for a vintage carbon type steel should be somewhere in high 50s hardness. It must be alloyed with something that moves the temper temperature up, because it doesn't seem any less hard. It's branded "OPARL 77", with "best silver steel" in the hollow. It's junk, but it does help illustrate the point that at these levels of keenness, the shave tells more than the picture of the edge. It's a shame that it's junk because it's a very classy looking razor.

The sharpness, with my hanging hair test, that this razor has is just barely catching a hair. Often when I've bought razors that have been professionally refurbished, they are somewhere in this ballpark, sometimes worse if they're not perfectly straight, which suggests a quick honing routine and no true test of shaving. Well, I don't often buy professionally refurbished razors, but I will do so if they are the same price as one that hasn't been cleaned up.

I almost dumped this razor on the classifieds without having honed it (it was NOS when I got it). I'm glad I didn't, it'll go to the garbage can when I can deal with the fact that it cost me 45 bucks and is worthless.

-

06-07-2014, 07:27 PM #6Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

One last comparison, I am not a RAD kind of person, at least not any longer. The next picture is of my daily shaver. This razor was last honed about 4 months ago, has hit a vintage linen probably 15 times, and has about 100 shaves on it. I'd expect if I used the linen on the jasper honed razor for 3 or 4 months the edge would become as refined as this.

The white spots on the edge might be skin or something, don't know. This picture is taken at the same magnification, but the bevel of this razor is much thinner than the others.

In other threads, I have said that when you find the right strop and linen, it's not necessary to hone very often, and this is why. This razor gets the japanese stone mentioned in this thread once every 3-6 months, and I generally don't shave with any others. I hone it to "normalize" it and make sure the edge is free of any accumulating defects, but it's noticeable that keenness is slightly off for the first week or two until it's hit the linen several times again. The linen has something in it, but it's not abrasive as you can see, as it hasn't necessarily removed much scratch depth. The polishing that the linen does is evident right at the very edge (some of the scratches just disappear into blackness), and perhaps some of that is from the strop, too, and also on the primary grind back from the bevel you can see quite a bit of black signifying polished area.

There's another thing that I think that isn't often discussed here, and that is the importance of finding a system that doesn't just blast away metal from a razor, as in this case green chromium oxide would not improve this edge, and it might do the opposite. Green chrome is slightly finer shaving than the stoned japanese edge in the first post, but at this point with about 100 shaves on this razor, it shaves better than it would off the stone again and at least as well, perhaps better, than green chrome (graded powder) would make it shave. at four months, I'm normally thinking that it will be time to normalize this thing again with the stone, but after looking at this picture, I think I'll wait a while until there's actually a problem that needs to be solved.

It is the best made razor I have ever seen of any type, it's exceedingly finely ground, absolutely perfectly straight, with extra weight from spine work in the spine and a nice heavy spine in general, and the tempering couldn't be any better. The few very vintage dennert razors that I have seen all display this skill in the grind, the cutler who made them must've been very proud of his work. This extra effort to not blast metal off of the edge has a lot to do with wanting this to be the razor that I shave with 6 of 7 days for the rest of my life without putting significant honewear on it. Hopefully that'll be another 50 years or so.

Some of this additional talk doesn't really illuminate much, we all have specific things we're looking for when we hone and shave and maintain a razor. The dennert razor, a vintage linen and a horse leather strop that is broken in and reflective are what I look for, but the pictures themselves illustrate why at this level of magnification, the relative differences are interesting but not always representative of the shave quality.Last edited by DaveW; 06-07-2014 at 07:39 PM.

-

06-08-2014, 01:57 AM #7Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Dave, what I am referring to is the edge on both razors as depected in photo Ozaki and the second photo labeled Jasper2.

The Jasper2 photo shows light reflection on the edge at several spots, some of which are at the termination of large deep stria. Now that may just be lighting in the photo, but both Jasper photos show the same reflections at the same spots. I suspect it is not a lighting issue, but in fact chipping at the edge.

Chipping at the edge is an indication of 1. The bevel was not set. 2. The last stone contains random sized or hardness grit that is gouging the bevel and resulting in chipping the edge. 3. Defect in the razor causing chipping or 4. Too aggressive a stone was used early in the progression to set the bevel and has weakened the edge steel.

A finishing stone should leave your edge chip free and straight with no light reflection at the edge.

If you could take a photo of the razors with the scope at 45 degrees to the edge as opposed to 90 degrees to the edge, you will be able to see if the bevels are meeting at the edge or chipping.

While you can possibly remove micro chipping by stropping on linen and/or leather, you should not have to. Stropping is done to reduce the land height and improve the comfort by microscopically making the edge finer and straighter.

This is consistent, with what you are finding that your edges are improving, after stropping the blade for multiple days after shaving.

A properly prepared finishing Novaculite, Black or Translucent will not leave a wire edge. It will leave an edge that can comfortably be shaved with off the stone, no linen or leather. Linen, Leather or paste can only improve the edge.

-

06-08-2014, 02:25 AM #8Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

At a lower magnification, I'd agree. At this magnification, the edges are very similar (based on their ability to sever hairs - the shave tomorrow morning will describe more). The idea of aiming for no metal particles at the edge at all under any magnification (and without stropping of any type) is a myth that would be achieved only if you had ended just on the stroke that reaches the edge on both sides, or if using a type of stone that cuts narrow deep grooves and leaves no organized wire edge. Some formation of a wire edge is a product of any stone working at the edge, even if it's just small particles like these were and not an organized burr like you'd have on a knife.

The aggressive bevel setter doesn't apply here, any work from a bevel setting stone has long since been honed off and the bevel is completely in plane with the stone with no pressure on the razor.

In terms of the dennert edge with a lot of linen work, there simply is no natural stone used under any conditions that will match or improve that edge, unless one would use one of those hones sparingly and not actually work all of the way to the edge, leaving the illusion that the stone has done super fine linen-type work just because the super fine linen type work is still there. A good linen will improve any stone, and also result in better edges off of the leather than straight from the stone. None of the current substitutes for linen that I've tried actually do that.

If any novaculite hone would ever be seen to have results looking like the dennert edge (with almost nothing there), it would be a case of lower magnification or lack of light to reflect off of the work of the novaculite hone. No matter how low the pressure and how good the technique, they're simply not as fine as either of these two stones. The best you can hope for them is to break a surface in on one as much as possible, and at the same time, have it as clean as possible.

In terms the amount of light, it may also be making the pictures misleading. This scope has LED lights at the lens, and the lens is almost right on the bevel, facing directly into it, as opposed to better lighting that's either more even or not facing right into the bevel. It's of this type:

Amazon.com: USB Digital Computer Microscope: Computers & Accessories

I'll concede that looking at the pictures, just strictly from visuals, it does look like the japanese stone has done a better job. But it doesn't so far appear that it's really as material as the pictures look, and judging from the first shave I had off of this stone, it was very similar to the ozaki, and far more keen than any novaculite honed razor I've used.

(we are sort of, also, getting away from the original reason I started posting this, which was to suggest to anyone considering the chinese green stones that they're not that great, and if cost is an issue, there are other options in stones).Last edited by DaveW; 06-08-2014 at 02:47 AM.

-

06-08-2014, 03:16 PM #9Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 458

Jasper shave report - can't edit the post that I made yesterday morning, it's just over 24 hours ago.

The shave off of the jasper stone was relatively indistinguishable from the japanese stone. I maybe shaved ATG with the japanese stone a tiny bit easier, but I could also be imagining that. Either way, the jasper is perfectly capable of maintaining the razor at a high level, especially once leather is involved, and linen (which wasn't used) would only improve the situation.

After shaving this morning, I went out of order and honed the razor on novaculite. Specifically, the black translucent stone from natural whetstone. I have about a dozen novaculite stones, and this one is the most dense of all of them (at about 2.9 specific gravity). The least dense translucent or black that I have is 2.6 specific gravity, and the difference in how close the particles are packed on one vs. the other is actually pretty significant.

Hone routine was 50 strokes with WD-40 and 150 with as close to the razor only weight as possible with a light mineral oil (the stone cuts finer on light mineral oil than on WD40):

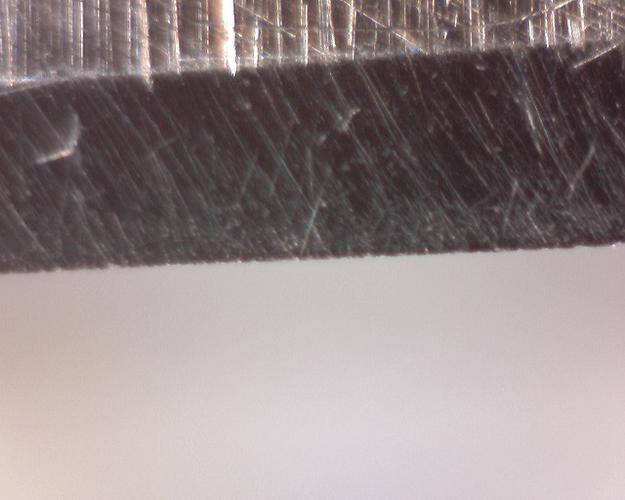

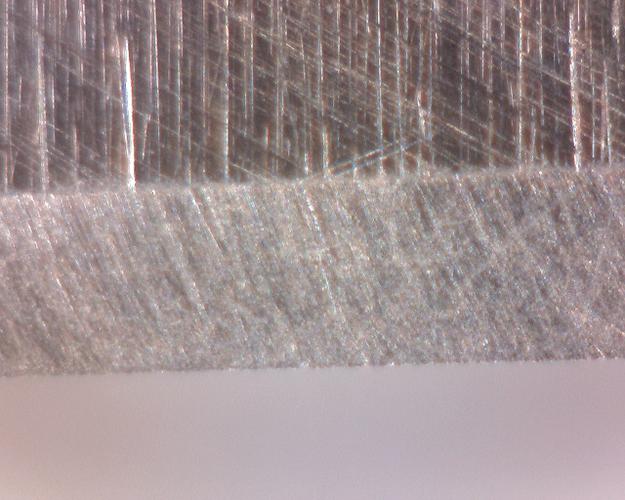

Here's two pictures of the resulting edge (they look about the same).

The bevel looks very scratchy on this stone, and I have to guess that the difference between this picture and tim zowada's is probably light reflection. The edge is still fairly uniform and this razor straight off of the stone easily catches a hair, and splits and and then severs it. Leather will make it nicer to use.

Pressure on novaculite is always more critical (to be as light as possible), and unlike the jasper and japanese hone earlier in this post, care has to be taken to notice any novaculite particles that break loose because they sometimes break loose in clumps, that may only be 10 or 20 microns in size, but those particles loose on the surface of a stone can really damage a razor.

Same as before, remember this is at 200x magnification, so what looks like a very scratchy edge here is a semi-bright polish to the naked eye.

I've shaved off of this stone before (with a good, keen, sharp feeling shave) and chose it because it's the finest one that I have. It would cut finer if it had several hundred razors through it, but I have a problem of excess and would rather use novaculites for tools and knives.

This stone came new from the dealer with a fairly coarse cut or lapped edge on it that is unsuitable for a razor. it is a better idea when buying one of these new to buy a junk chisel or plane iron and work the surface continually for a few minutes, then apply oil and wipe it off (to remove particles) and then work the surface with a plane iron again, alternating between working the surface and removing the particles until the stone seems seems to be cutting very fine. Then hone a razor on it and continue to wipe the oil off until the oil that ends up on top of the razor shows pure and clean with no particles.

One of the people who got me into straight razor shaving has been using horse leather, a single black arkansas stone (both for his tools and razors) and has been using the same razor and same stone for 40 years, where the tools have conditioned the stone to be very fine cutting and worn in, and technique in flattening the backs of tools keeps the stone flat.

Cost of this stone: $119 + shipping.

Will report on the shave off of this stone tomorrow.

EDIT: Shave was acceptable, but not up to par with the jasper stone or japanese stone. This razor, however, would be improved greatly by the linen, which I have abstained from using. It is also much keener than it was when I got it, despite being advertised by the seller as "shave ready" (I don't ever factor that into what I pay, so it doesn't matter), it's just short of the novaculite and japanese hone edge. I've not looked at a novaculite edge under this crappy hand held microscope before, but something isn't quite adding up. This is my densest finest stone, but I'm forgetting something or someone else did something to it on loan. I'll use a stone that's not been loaned out and redo novaculite at the end of this, perhaps several.

Chinese stone pictures tonight after I hone on the chinese stone, which was the original motivation for this thread - my opinion before honing is that I have not been impressed with the chinese hone for tools, and it's broken in plenty to get a good idea of where it is. The fact that the novaculite is coming up just short of what I'd like will give it a chance to prove whether or not it can improve an edge.Last edited by DaveW; 06-09-2014 at 11:44 AM.

-

06-08-2014, 04:30 PM #10Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So what is a dennert edge?

The best solution for economy honing for a novice is inexpensive, proven synthetic stones, e.g., the Super Stones, or film.

To recommend a natural stone to a novice honer leads to frustration and usually a more costly learning process. An inexpensive, untested hone is false economy.

Don’t get me wrong, as a long time stone collector I understand the chase, but naturals are natural and almost any two are not alike, they can’t be, they are natural there is no quality control.

Your jasper, whatever the reason, does appear from your photos to be chipping the edge. As suggested some 45 degree photos will clarify the issue.

The edge off your Ark stone appears much straighter and less chippy than your Jasper edge.

As you have said, your ark can still be improved with more hard steel applied to it. I have been shaving off Ark edges for over 40 years from the same stones, they are capable of producing fine edges.

More importantly, the shave… is all that counts.

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote