Results 191 to 200 of 382

Thread: Hard Arkansas

-

09-02-2014, 07:23 PM #191The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

What was meant by "worn wet and dry" (if you have not already figured it out) is the cutting action of a used up piece of "wet/dry" sand paper. When its fresh and new, its has a lot of "bite" to it, but as you use it more and more, it no longer cuts as quickly, or as deeply. Best way I know of to describe it, would be to picture a bundle of a dozen sharp pencils pointy side up. This would be "new paper" as you use the pencils the pointy end wears down more and more until you would eventually achieve points that are softened, rounded, or possibly even as flat as they were before they were sharpened. Its still the same 12 pencils, made of the same graphite in a wood matrix, but now the points don't make such a fine line.

In essence, this is the exact same thing that happens to the surface of an Ark stone. freshly lapped has many exposed points. as you use it, the points wear down.

-

-

09-02-2014, 07:32 PM #192

Thank you Gentleman for answering my questions...

-

09-03-2014, 04:53 AM #193Member

- Join Date

- Nov 2012

- Location

- In the heart of Germany

- Posts

- 86

Thanked: 30

-

09-03-2014, 05:43 AM #194

Phrank, I used to work in the auto body trade and we used a lot of wet and dry sandpaper. As a sandpaper wears, it losses it's cutting power as the particles 'wear down' and slowly become less efficient. So in effect it slowly goes up in grits. What was a 220 slowly works it's way to perhaps a 400-600. When I found that the paper wasn't cutting, I'd change paper with the exception of when sanding for final prep before painting and then I'd use it until it was almost useless.

I hope this makes sense.

Sorry I was late to the party with my explanation. Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

09-05-2014, 07:51 PM #195

Just got back from Dans , met Dan and his son Sherlen got a tour and quite a few stories oh and picked up a super looking black Ark ,,my friend Glen is going to have a laugh at this, he knows I dont hone , heck he's had my Zulu for a few months ,but I couldn't help myself , if you get a chance this is a great stop while out on your bike, very nice people. And their history is fun to listen to. Dans a very interesting man. I'll get some pics up after I get in from the rally. Tc

“ I,m getting the impression that everyone thinks I have TIME to fix their bikes”

-

The Following User Says Thank You to tcrideshd For This Useful Post:

earcutter (09-06-2014)

-

09-08-2014, 11:23 PM #196

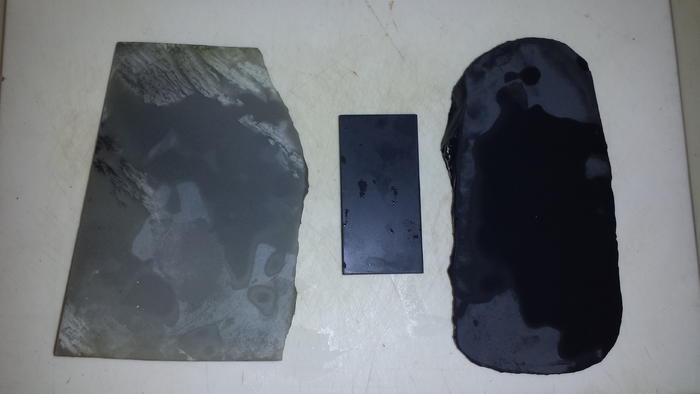

Soo....Got these finally. They are stupid huge. Especially the translucent. These are going to be a b!tch to break in. That little sucker in the middle is a 4x2 black trans. The large black has no translucency at all. the translucent is an inch or so at its thickest and the light on my cell can be seen right through. The only complaint I have about these is that they're not chamfered on the edges and on the black thats going to be hard to do. The translucent at least has that large side completely straight so that will be easier. Oh and they have some pieces that flake off on the backs because of the rough cut.

Now I am just thinking about making a fitted box for each. I think I will do something like glass bedding these, The only problem will be making sure the release agent gets in all the nooks and crannies. Any ideas?

-

09-08-2014, 11:55 PM #197

Wow - those are spectacular! Congrats!

Sorry - I know nothing of bedding.David

-

09-09-2014, 01:33 AM #198

Ya making an Arkansas side walk? LOL

Fantastic looking stones, congrats. I used a dremel with a sanding wheel to knock the edges down. A belt sander would work great I think.

-

09-09-2014, 01:51 AM #199Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

-

09-09-2014, 01:53 AM #200

I need to get mine all shiny like that. I'm working on it but it's slow going.

275Likes

275Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

! I got the hone in the German bay (dirt cheap btw...

! I got the hone in the German bay (dirt cheap btw...  ) and unfortunately don't have any background information about it.

) and unfortunately don't have any background information about it.

(you know, like Germans loving the thuringians and Belgians the coticules)...

(you know, like Germans loving the thuringians and Belgians the coticules)...