Results 11 to 20 of 41

Threaded View

-

09-30-2014, 10:02 AM #1Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

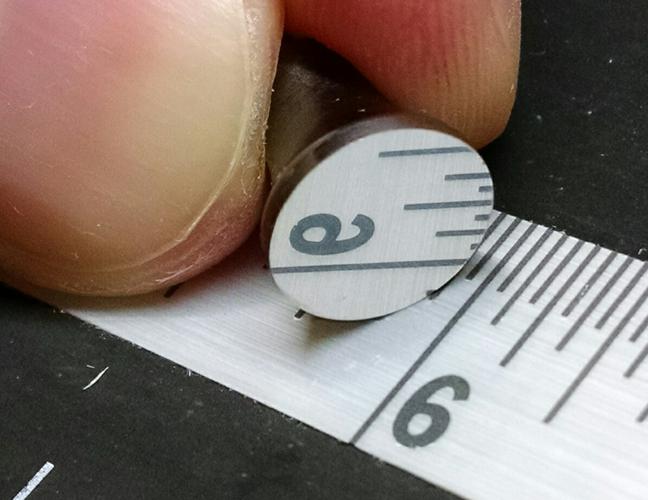

Thanked: 246 Anybody have any ideas as to what this might be?

Anybody have any ideas as to what this might be?

New natural stone I'm trying out - found this near a glacial lake and decided to give it a try. Looks like a sort of layered sedimentary type of stone, and it slurries up pretty quick with an Atoma 400. The slurry seems to break down like a JNat.

OK, tried slurry on water and plain water and it cuts at a fairly decent speed on the slurry for the fineness of the stone, but doesn't finish at its best on water. So I tried switching to oil and holy moly!

This thing puts on a sweet finish with the same method as my black translucent Arkansas, except it's an even better finish (and only lapped with an Atoma 400! no crazy steel rub-a-thon necessary) and seems to cut even faster also. Honed up a razor tonight but won't have enough growth to shave until tomorrow as I just shaved last night. The stone reminds me a lot of the black trans Ark as far as feel and finishing procedure. I am really happy with this thing so far! Now just got to see how it shaves.

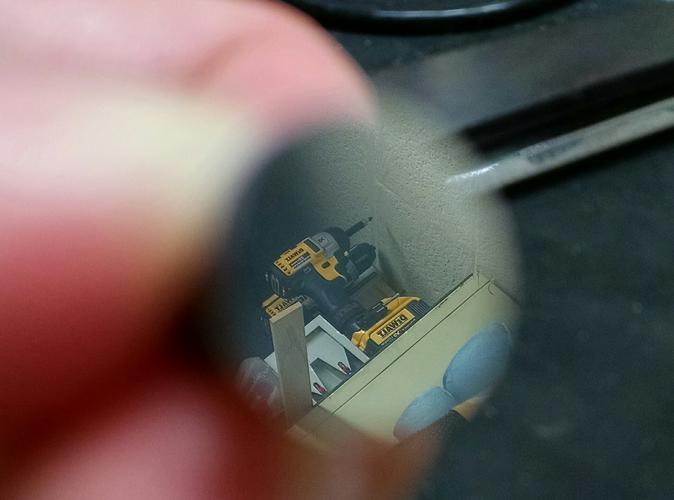

Here are shots of the natural side and bottom that I didn't cut off that might help with ID.

Last edited by eKretz; 09-30-2014 at 10:11 AM.

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote