Results 1 to 10 of 41

-

09-30-2014, 10:02 AM #1Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246 Anybody have any ideas as to what this might be?

Anybody have any ideas as to what this might be?

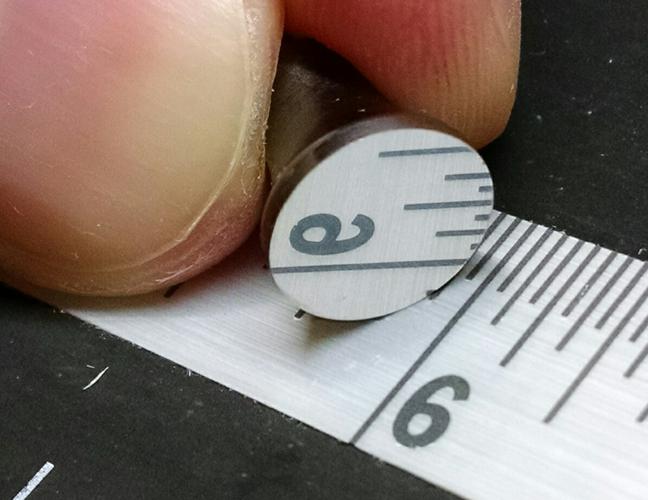

New natural stone I'm trying out - found this near a glacial lake and decided to give it a try. Looks like a sort of layered sedimentary type of stone, and it slurries up pretty quick with an Atoma 400. The slurry seems to break down like a JNat.

OK, tried slurry on water and plain water and it cuts at a fairly decent speed on the slurry for the fineness of the stone, but doesn't finish at its best on water. So I tried switching to oil and holy moly!

This thing puts on a sweet finish with the same method as my black translucent Arkansas, except it's an even better finish (and only lapped with an Atoma 400! no crazy steel rub-a-thon necessary) and seems to cut even faster also. Honed up a razor tonight but won't have enough growth to shave until tomorrow as I just shaved last night. The stone reminds me a lot of the black trans Ark as far as feel and finishing procedure. I am really happy with this thing so far! Now just got to see how it shaves.

Here are shots of the natural side and bottom that I didn't cut off that might help with ID.

Last edited by eKretz; 09-30-2014 at 10:11 AM.

-

09-30-2014, 01:04 PM #2Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Indian love stone??

CAUTION

Dangerous within 1 Mile

-

09-30-2014, 02:06 PM #3Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,456

Thanked: 4830

Oh Bill that cracks me up every time. There are several rock hounds here, but only one that I can think of with a serious background in geology. What it is is not as important as what it does. I am waiting for your shave report. A once polish is only good if it can shave well. Give it some time and sooner or later bigspendur will be around.

It's not what you know, it's who you take fishing!

-

09-30-2014, 02:20 PM #4Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Heh, must be a running joke that ran right past me!

One more data point, the stone can be broken away by hand if there's a thin sharp edge (I guess most any rock can), but when it's thick and square is pretty darn strong. When I first started playing with trying out some small sample pieces to see if they'd even cut hardened steel, I tried breaking off some small pieces with a chisel and a 4 pound hammer and got nowhere. After about 5 minutes all I had was some tiny shards - the chunks that sprayed out from the chisel edge. Finally got about a 1 square inch piece and tried it, but only found that it was able to cut hard steel, there wasn't enough there to do much more. After that I went straight to the diamond cutoff wheel.

-

09-30-2014, 04:57 PM #5Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

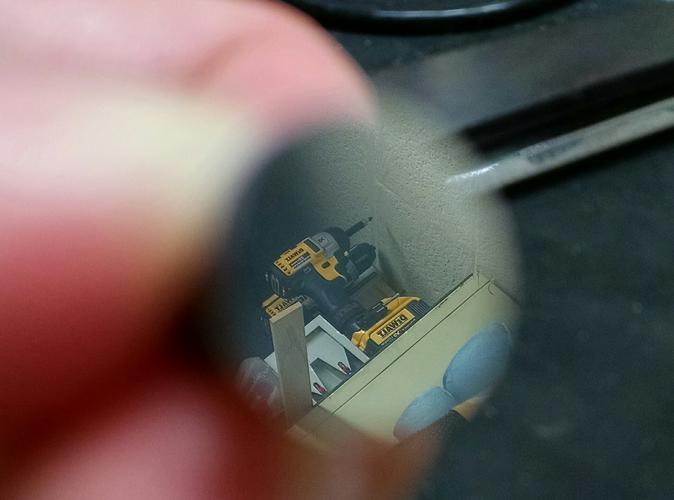

Here's a quick test I did on a knife - the sides of the knife started out with a pretty dull finish from a DMT 320 plate, so I didn't expect to see much of a difference in finish since this is a pretty fine stone. I slurried up the stone with an Atoma 400 for about 10 - 15 seconds then started honing on the side of the knife - I only honed on one side so I could compare. The slurry started to darken after about 20 - 25 strokes and I only honed on the side of the knife for a couple minutes. The pics show an original DMT 320 finish, the side I ground with the new stone (you can start to see the mirror reflection showing up, but the original's a really coarse finish so it's only showing in a few spots) and the stone after the couple minutes of honing - the darker slurry is from after honing, the lighter is fresh slurry I raised after honing for a visual comparison.

-

09-30-2014, 05:13 PM #6

I notice there seem to be some vugs (small holes) in the rock. That is very common with limestone where water starts to dissolve the rock and also in certain igneous rocks where as the rock cools bubbles form which turn into small holes which many times contain xtls of various kinds.

I don't have a clue as to what it is though. You could do some simple hardness tests and if you had little dilute acid you could test for limestone.No matter how many men you kill you can't kill your successor-Emperor Nero

-

09-30-2014, 06:09 PM #7Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Can you give me further info on testing? I would like to discover what the heck this is for sure. I figure it is at least 6 Mohs if it cuts hardened steel, right? What sort of acid would I need? I have some Bar Keeper's Friend - would the amount of oxalic acid in that do anything to help ID? I don't think I have anything else besides vinegar ATM.

-

09-30-2014, 07:25 PM #8

Try to light it on fire and see what happens.

-

09-30-2014, 07:58 PM #9Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Uh. Yeah. Anyway, tried the vinegar after reading that it should bubble if it's limestone - no dice, the vinegar just sat on top of the stone like water. Same with oxalic acid paste.

-

09-30-2014, 08:08 PM #10

Yes vinegar will bubble on limestone. Use a steel test too.

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote