Results 1 to 10 of 15

Thread: CROX on a frosted glass

-

01-19-2015, 04:26 PM #1Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168 CROX on a frosted glass

CROX on a frosted glass

Theese days i read a few threads about diamond paste on a Spiderco Uf , and because i was truyng to get myrusian STIZ 65 into a sharper condition , i decide to try it .

I took a piece of glass , round the edges very well ( very important ) , took my Makitta 1200 stone ( King ) and i began to lapp it on the wet glass.

With a litlle presure i got my fine frosted glass , and i put som thin oil and a poudered crox , on it .

I cant believe the speed that the crox work this way a few strokes are ENOUGHT , or you will kill the sharpness .

Even the hard rusian razor gets very sharp .

For me thoose are the best results that i have with crox .

If some of you have an experience with this kind of honing , please feel free to respond .

-

01-19-2015, 04:36 PM #2

thank you for sharing RusenBG ,Now I've something else to try my hand at.

-

01-19-2015, 04:44 PM #3Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

I kind of like chrome ox (don't use it, but used to) on a surface that has a little give.

A hard surface if I had a lacking finish stone would be a nice way to set final geometry, though. As you mention, it cuts so aggressively that you can trouble the edge.

On a hard surface, graded crox (and not a wax buffing stick) is essential. Glass and large al-ox particles in some of the buffing sticks (to speed up the cut rate) don't mix.

MDF is also usable if you oil it and use it some, it will become slick, and it's cheap. It's sort of halfway between a hard surface and a soft one.

-

01-19-2015, 05:36 PM #4Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

I forget to tell you that the first experiment was a deseaster for my razor .

I make the frosted glass with a 400 grit sand paper ,and first i try it withowt oil , water only . The first impresion , the draw and evrything was , like a dream . The gritted glass cuts agresively , like a ceramic plate ( so it is a ceramic plate ) pops hairs very sharp ,butt when i look under 30 magnification i can not not imagine ,that i give my blade , such a chipp ,in 1 place .

So after rehonning this rusian hard steel , i decide, to try with a smoother grit and frosted finish from 1200 grit Makitta - king stone.

May be the best option , is to make the frost with a 2000 or 3000 grit stone or slurry and it is very important to properly clean it ,with dish washing detergent and runing water .This will asure you no residue ,from the glass particles that cuts agresively like diamonds and like novaculite slurry froma a Cretan hone , so called turkey oil stone .

Using oil and light presure is imperative , for geting optimal results between sharp and smooth, and the most important thing , not to microchipp and destroy your edge .

I am no honing pro , newbe , but practice is what matters for me . Theese observations are basic , but i am reached so far at this point of observation and i can tell that , if it is done properly and lifghtly , it works better than my blue green Esher , at the 3 dificult razors .

I think that everyone that tries this , have to be a little bit advanced with honning and to know exactly what he is doing or he could ruin his edge ( like me ) .

It is cheap to experiment and it gives good results . the oil i use was a sewing mashine , thin oil , i use it om my razors after shaving as anti rusting and for oiling my new strops that i make my self , from naturaly tanned cowhide 4 mm thick.Last edited by RusenBG; 01-19-2015 at 05:43 PM.

-

The Following User Says Thank You to RusenBG For This Useful Post:

DaveW (01-19-2015)

-

01-19-2015, 05:39 PM #5Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Good point about the freshly abraded glass having cutting power of its own, that's certainly true.

Now..who is going to be the first person on here who abrades glass and uses it to set a bevel!!!

-

01-19-2015, 05:51 PM #6Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

Ha i have two ceramic plates , cut from a theracot ceramic floor cover . They are lapped and they take steel agresively - the swart darkens in a few strokes - i have set 2 bevels theese days with them . they leave very fine consistant scratch patern , like a 1000 grit stone , exept they are faster . They work magnificent on my knives and with 2 rasors , the question was to find a fine ceramic finisher ha ha ah

-

01-19-2015, 07:57 PM #7

Interesting experiment. Can you post a picture of the glass?

-

01-19-2015, 08:05 PM #8

When you hone with this CrOx on glass do you use an edge first honing stroke or an edge trailing stropping stroke?

What a curse be a dull razor; what a prideful comfort a sharp one

-

01-20-2015, 05:41 PM #9Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

Honing stroke , X stroke also . It maybe wrong , i open this thread , because this question bothers me for a long time . Please experiment and feel free to tell your observations , i am going crasy may be .

The worst case scenario is to degrade an good edge , so to avoid misleading if you do it , do it sceptical , lets not give to the passion cheats us that it work marvelously .

-

The Following User Says Thank You to RusenBG For This Useful Post:

Steel (01-20-2015)

-

01-20-2015, 08:07 PM #10

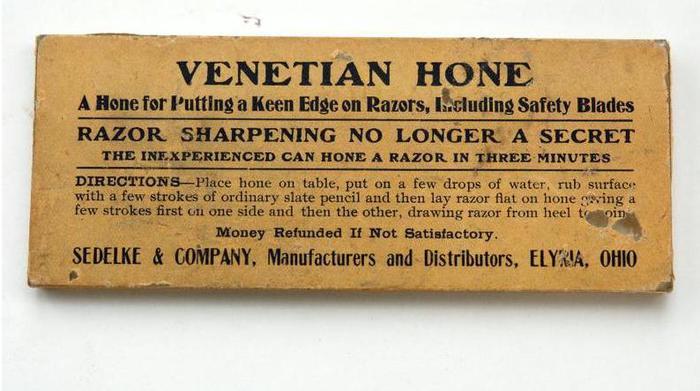

As a matter of fact this is not a new idea, but in fact quite an old one, and I can attest that it works quite well, especially to refresh a blade. Here is a picture of an old Barber Hone that was manufactured and sold on this very principle of using 'Glass' as the finishing surface. Although it was designed to be used with ordinary pencil lead (Graphite) I see no reason why CrOx wouldn't work as well...

Here is a pic of a 'Venetian Brand Glass Barber Hone' in my collection:

WP34 Lupus Cohors - Appellant Mors !

Lupus Cohors - Appellant Mors !

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

Steel (01-20-2015)

12Likes

12Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote