Results 11 to 20 of 24

Thread: Arks? Where to buy?

-

05-10-2015, 04:27 AM #11FrankC

- Join Date

- May 2014

- Location

- Olympia Washington

- Posts

- 271

Thanked: 52

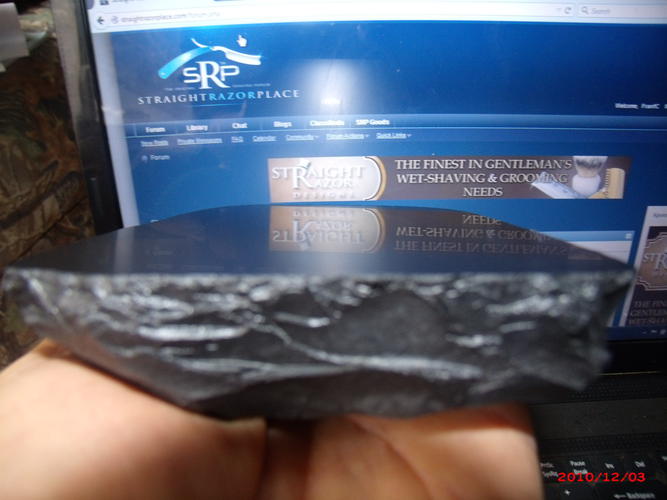

I purchased this one from Dan's, it's a primitive and took plenty of work to get it prepared for razor work. I would purchase from them again in a N.Y. min.

It's their extra fine black and 100+ laps from a 10K finish, on a very light coating of oil will do very nice things to an edge.

-

05-10-2015, 05:09 AM #12

I don't know how to break them in?

-

05-10-2015, 05:55 AM #13

SolitarySoldier,

It seems that you 'work' the surface of the Ark to polish a variety of hardnesses of steel - e.g. some carbon steel knives, some stainless knives etc., etc.

Have fun

Best regards

Russ

-

05-10-2015, 06:21 AM #14FrankC

- Join Date

- May 2014

- Location

- Olympia Washington

- Posts

- 271

Thanked: 52

SS: If you want to know about these stones do a search for wid's thread here called Hard Arkansas? I think it's 38 pages and you will learn all about how to break them in. If you want a finisher get a black or trans then the fun begins.

Basically when you receive one it needs to be lapped very flat and then taken up in finish grits on W/D to 2K, once dead flat and 2K finish then stone needs to be burnished.

I did mine on oil and a bar of tool steel, with pressure rubbed the whole surface of the stone for hours and hours, you will see the stone getting very shinny, this is the surface that you are after. These stones are very hard and it's really a labor of love, takes allot of work but is worth it. I worked on mine for a solid week,several hours a day, when finished and in use they just keep getting better the more steel that you put across it.

FrankC

-

05-10-2015, 04:44 PM #15Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here’s the Cliff Notes…

Grid the stone face with a marker, lap it on a flat surface and a new piece of 600 grit Wet & Dry. Look at the surface and see how much of the marker came off.

If it is not very flat, some loose silicon carbide from GotGrit.com will get you to flat with some 60 or 80 grit then work up to Wet and Dry. Finish on 1 or 2k and burnish with flat carbon steel knife or chisel and oil.

Lots of laps and pressure, lots of pressure and hundreds of laps, the smoother the face the better the finisher…

It is a bit of work, but only needs to be done once. Water, Smiths or Oil works well, wash with dish soap if you use oil. Lots of laps or micro bevel.

Worth the effort.

-

05-10-2015, 05:18 PM #16

Last edited by Orville; 05-10-2015 at 05:23 PM.

-

05-10-2015, 05:56 PM #17Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

I use more radical mesures in lapping hard stones . 80 or 120 grit corund on a glass plate and few renew the grit . After the coordinate system is all goon , you can mouve to a finer grits to polish .

What is the prise of theese primitive arks .

-

05-11-2015, 05:03 AM #18Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

She isn't mistaken. For woodworking, they are ready out of the box. They aren't marketing the stone for sharpening razors - most of their clientele would use them for sharpening chisels or the like. They would work fine out of the box for shaving too if we had no nerves in our faces, lol. They still will produce an extremely sharp edge out of the box, it just wouldn't be comfortable to shave with.

-

The Following User Says Thank You to eKretz For This Useful Post:

Orville (05-11-2015)

-

05-11-2015, 03:11 PM #19FrankC

- Join Date

- May 2014

- Location

- Olympia Washington

- Posts

- 271

Thanked: 52

-

05-11-2015, 08:24 PM #20

I just got my translucent from Natural whetstones, I haven't tried on straight razor yet, because I need to burnish it. It is a beautifull stone it is 6x2x3/4. I already tried on a kitchen knife and it is not slow at all.

12Likes

12Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote