Results 51 to 60 of 62

-

02-26-2016, 04:48 PM #51

Hedwig and the “Angry Inch” thread.

-

The Following User Says Thank You to MODINE For This Useful Post:

Slawman (09-30-2016)

-

02-26-2016, 06:00 PM #52Senior Member

- Join Date

- May 2014

- Location

- Bryan, TX

- Posts

- 1,251

Thanked: 228

Whatever...............the reason! I reiterate........it works for me!

Mike

-

02-26-2016, 09:00 PM #53Senior Member

- Join Date

- Oct 2015

- Location

- Switzerland

- Posts

- 104

Thanked: 52

i hope i won't heat up this discussion too much by adding my thoughts... and i also hope that i am not completely wrong...

if we have a evenly warped blade from heel to toe with a constant width over the whole length of the blade, it touches a flat stone only at the heel and the toe. while doing the perfect x stroke, the blade touches the stone with its toe and at the edge of the stone, nowhere else. so the edge of the stone does the work. i think gugi is right here. and i don't think it is necessary to draw a line when you realize that the edge does the work. an 1" wide area not at the edge won't do any work at all.

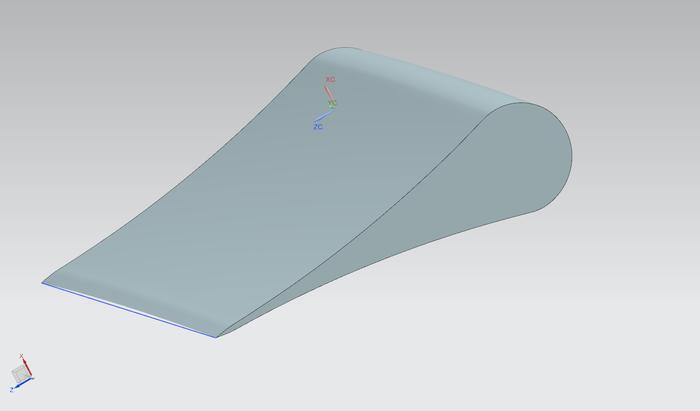

however, it is possible to use any area of a flat stone. to illustrate this i made a few screenshots of a slightly warped blade i drew with CAD.

this is a warped blade, constant width, convex side up. the blue line near the edge is straight:

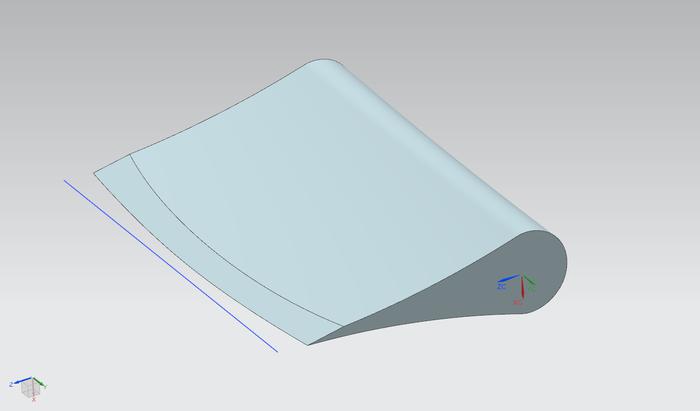

when you heavily work the concave side only on a flat stone without using the edge of the stone, you'll end with a uneven bevel and a smiling edge like this (concave side up):

now you could apply rolling x strokes on the convex side to get an even bevel there.

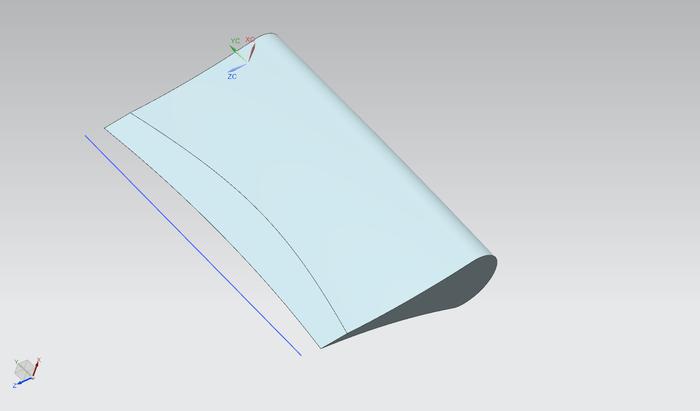

if you heavily work the convex side only, you get an uneven bevel and an ugly frown like this (convex side up):

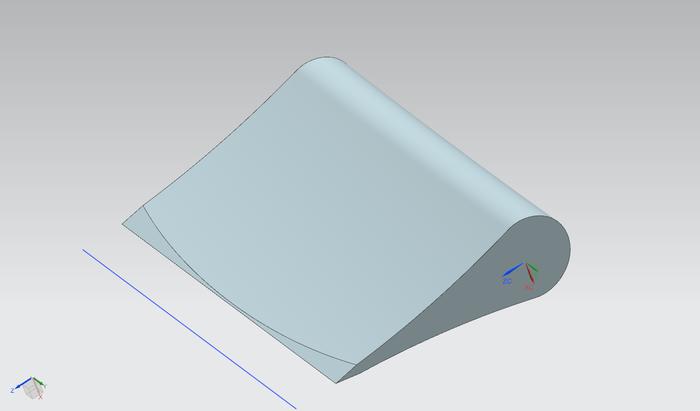

if you work both sides you can get rid of the smile or frown, but you'll loose a lot of steel. so this is not really recommended:

i hope these images help a bit to understand what happens to a warped blade on a flat stone.

regards,

hansLast edited by brightred; 02-26-2016 at 09:05 PM.

-

The Following User Says Thank You to brightred For This Useful Post:

Slawman (01-26-2017)

-

03-09-2016, 08:06 AM #54Junior Member

- Join Date

- Dec 2014

- Location

- Walla walla Washington

- Posts

- 13

Thanked: 1

I read the post and then tried the method and it works. I, also , got further in 5 minutes on a warped wedge then the prior two hours of honing accomplished. Thanks for the info

-

03-09-2016, 08:07 AM #55

-

03-18-2016, 03:49 PM #56

-

03-18-2016, 05:45 PM #57Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

On a warped blade, the concave side keeps the blade off the stone, how much warp will dictate how high off the stone. Fortunately most are slightly convex/concave and all that happens is the bevel is narrower at that point where it does not make full contact because of the bridging effect.

Part of what makes the Rolling X and the “1inch” work, is they allow the heel to fall off the edge of the stone and the concave part of the edge to make full contact with the stone, how much depend on how concave the razor is.

Those of you that use Super Stones can see this, as they load typically more near the edges, when using these strokes. I see this all the time with my 12k Super Stone and have taken to rounding the edges, as opposed to beveling where I felt a slight grating with a beveled edge. Simply rounding solved that.

You are not honing on the edge/corner, but a quarter to half inch from the edge. But if the corner is sharp you may feel it.

A tapered narrow bevel can often be evened out with a rolling X or 1 inch honing technique where the razor is slightly concave. Misshaped heel and high stabilizers are other issues.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

JackeHj (03-20-2016), MisterClean (09-30-2016)

-

03-18-2016, 06:18 PM #58

In reality, the only advantage of a narrow hone is the possibility of using both edges of the hone to reach into the concavity of a warp (or a frown for those who hone those).

What people call 'rolling' is the honing of convex edges on flat stones i.e. smiling or the convex side of a warped blade. It isn't anything complicated, mysterious, or particularly difficult. It's simply making the whole edge rub on the stone because a convex razor touches the hone only one point at a time.

The first lesson in honing (evidently missed even by some who charge money for it) is the necessity of paying very close attention at what is going on - namely where the razor edge and the hone are in contact. Because in most cases that isn't the whole edge but only a small part of it.

You can draw lines, circles, checkers, chevrons, or rorschach figures to help you with that, what actually matters is ensuring that every point along the edge gets rubbed on the hone.

And if you happened to be honing a warped blade (or frowned) you can choose to take advantage of the fact that the contact point between the concavity of the warp (or frown) and the hone is the edge of the hone and use this the same way you use the visual feedback from the water bead when you hone a regular razor.

-

-

09-30-2016, 04:59 AM #59

This discussion is very interesting, I learn more everyday I tune into SRP. I'm hooked....

Freddie

-

01-15-2019, 05:44 PM #60Senior Member

- Join Date

- Nov 2016

- Location

- Germany

- Posts

- 111

Thanked: 30

Great thread gens!

The solution for my slightly frowned edge was to work a little more ob the tip and ghe toe of the razor.

Only 2 timed dulling them on the stone and bringing back the edge on the king 1000 has solved it.

The smile introduced to the edge is almost not visible to maked eye but the frow is gone!

Regards

PhilippLast edited by Philipp78; 01-15-2019 at 10:53 PM.

108Likes

108Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote