Results 21 to 27 of 27

Thread: My CNAT Lapping Journey

-

07-04-2017, 02:44 PM #21Senior Member

- Join Date

- Mar 2017

- Location

- Calgary, Alberta, Canada

- Posts

- 321

Thanked: 41

I understand that your path is optimal, but since I'd like to avoid buying more stuff, I need a suboptimal path

So, 400 grit sandpaper to remove the scratches, then what?

I have a variety of handyman tools (including wrenches, screwdrivers, a small chisel, etc.) , a few small AlOx hones from Lansky (70-1000 grit), a few small diamond hones from DMD (320-1000 grit), a large coarse/medium hone, some green compound (particle size unknown), and small strops (balsa and leather on paddle).

If the hones are a no-go, then I suppose my options are to use a big wrench (on the smooth side) and the green compound on the paddle strop. Does that make sense?

-

07-04-2017, 09:13 PM #22Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Could always try to hones on a side to see if they scratch or polish. Otherwise I'd just go with the wrench and the compound.

-

08-14-2017, 01:35 PM #23Senior Member

- Join Date

- Mar 2017

- Location

- Calgary, Alberta, Canada

- Posts

- 321

Thanked: 41

So I finally got around to do it.

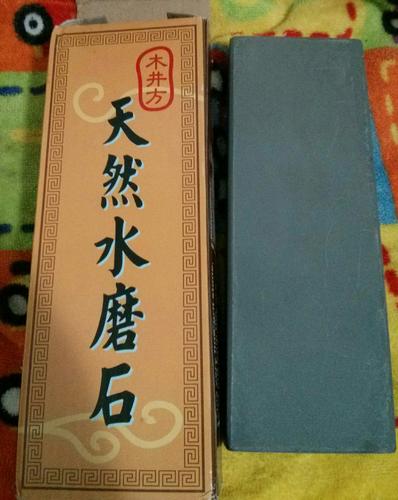

I flattened my hone. I also did the same the CNAT a little bit to remove the scratches. Here's the set-up.

Then I used the 1k Lansky hone and light slurry formed. Then I went to town with the wrench. It was doing an annoying 'eee-eee' sound on every stroke.

My CNAT certainly feels smooth, but not glassy (like I've seen for well-burnished coticules). The result:

So my question is: should I move on with the CrOx, or I have more work to do?

-

08-14-2017, 01:50 PM #24Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

I still see some scratches on that stone. Are those from the 1K, or are they left over from something else? Id from the 1K, do you have 2K sandpaper or something similar you could use to work them out? Or better still, did it come with a slurry stone? Those can also be used to work scratches out.

I don't think CrOx on that surface would be very helpful so I'd look to get it a little smoother first. At least scratch-free.

You could also try honing a razor on it to see if you even feel the need to burnish it any further.

-

08-14-2017, 02:06 PM #25Senior Member

- Join Date

- Mar 2017

- Location

- Calgary, Alberta, Canada

- Posts

- 321

Thanked: 41

I'm not sure those are scratches per se. I guess I have to take pics from a few angles.

That being said, I'm sure there were no scratches from the 1k hone.

One observation. The wrench I used had lots of small grooves - most likely something meant to increase grip. By the time I stopped, most of those on the contact surface were gone - leaving me with a smooth surface - except for a few spots. Perhaps that indicates inadequate flattening?

Obviously 'try honing a razor' is a test I'm trying to postpone, since I never honed one yet

-

08-14-2017, 03:27 PM #26Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

I think it's more likely that the wrench wasn't flat. Those bumps are from casting, and on cheaper wrenches aren't cleaned up. You don't see that on pricey wrenches like snap on, Mac, and Matco. It's to save money on production, not increase your grip, so you can probably imagine how flat the wrench is.

When I used a wrench to burnish, I used the polished surface they stamped the company name and size into. But I guess technically any surface of the tool will do the job as the idea at this phase is to knock down any high spots and reduce cutting speed in favor of a finer finish.

I guess if those aren't scratches you can move on to CrOx and see what you get.

-

08-17-2017, 07:00 PM #27

Some CNATs will never get glassy.

Just worry it with some 'flat steel' The deep scratches that you might see that run the length

of the rock are a do not care as long as the bulk of the surface is flat and burnished.

If you have lucked into a good CNAT that works as a good finisher do not be too concerned

if it dishes even as much as a dime. In my opinion a finisher with a light touch is allowed

to produce a micro bevel in its own way. Keep your bit of steel handy to worry and burnish the

hone flat where the razor does not so it never dishes more than a dime (or less).

CrOx burnished on the surface might help. It is unlikely to hurt. If all else fails try

vaseline and allow swarf to build up from your burnishing steel.

Finishers are a mystery.... if you have one you like KEEP it.

I have a small block of CNAT that I have been using to clean my Nanawa 4k and 12k hones.

It is picking up a polish. If you have a modern fine hone wipe any fine slurry onto the

CNAT and worry it with sacrificial steel and see what happens.

17Likes

17Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote