Results 11 to 20 of 24

-

07-11-2017, 02:37 AM #11I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

07-11-2017, 02:55 AM #12Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Just water. It's my normal thing, but this stone needs to settle down a little bit from an atoma 400 lap. I don't usually use anything else (to lap) and I don't finish on slurry too often.

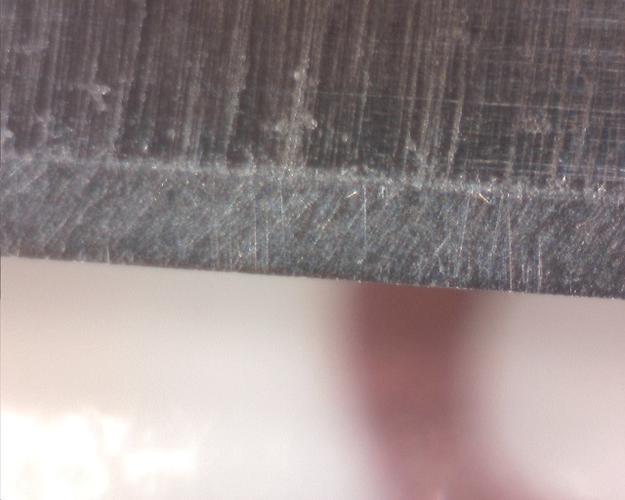

This is the razor having worked a little bit more on the stone surface. Still a little scratchy, but the edge appears reasonably nice, little damage after the linen and leather.

I expect a decent shave tomorrow morning (this is the carbon steel henckels, probably why the edge looks less beat up than the stainless razors on the prior page). I may be short changing this stone because I don't believe it's genuine, I'll work it a while longer to see what it settles down to, and keep the atoma 400 off of it.

Last edited by DaveW; 07-11-2017 at 02:58 AM.

-

07-11-2017, 02:58 AM #13I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

The Following User Says Thank You to mainaman For This Useful Post:

Steve56 (07-11-2017)

-

07-11-2017, 02:59 AM #14Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

-

07-11-2017, 01:54 PM #15Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Good shave, but nothing I haven't had before from other common stones. Certainly a stone capable of finishing a razor, but I was hoping for magic and unicorns! Can someone point me to a good discussion of sharpening on slurry. I have done it before, but it's not my thing so much and I haven't put the time in to "learn" it by feel and experience.

Before I do that, I'm going to burnish the top of this stone with an ozuku tomo that I made that's really too hard to be a tomo nagura (a lesson learned the hard way).

-

07-11-2017, 08:18 PM #16I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

07-11-2017, 08:26 PM #17Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

That's familiar to me. I have read a lot about craftsmen supposing that the grit is breaking down on a stone, but silica is not that fragile, and neither is most natural alumina.

I have also heard about a lot of people honing on slurry and talking about their results, but figure that they aren't understanding it at a scientific level. We're all wired a little bit to want to confirm that we've done something properly.

With that said, given silica's inability to cope with iron carbides, I have figured that what's actually happening with slurry refining is that the particles are getting more dull, but not necessarily much smaller, and on top of that, they are loading the surface of the stone a little bit (if it has any porous parts, given that pores themselves act like small cutting areas).

Have you ever seen anything definitive? With the various folks now using electron microscopes, etc, we should at some point get a picture of slurry before and after.

All of that said, honing with a method is a craftsman-like activity. Part of it is trivial knowledge of the process, but a whole lot is the feedback loop between the craftsman and the results, and the subtle subconscious improvements that we make that don't fit well on a bullet point instruction list.

Any thoughts, Stefan? I know you're pretty far into the jnats, etc, and you're not likely to provide me with "funny" information just to do it. I like to know everything at a simpler and deeper level (I stole that from Fred Rogers), but I just haven't gotten around to perfecting slurry honing beyond what's shown in the video, and really learning it.

-

07-11-2017, 08:36 PM #18I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

The Jnat particles are flat like flakes. The whole structure of the stone is layer -like and so the break down (according to the Japanese there is break down) must be happening in one or both of two ways. Shearing of the grit flakes which produces thinner flakes, and/or fracturing into smaller pieces. I do not believe anyone has really looked into what exactly is happening to the grit while honing a razor. The undisputed fact is that finishing on slurry produces superb edges when the right combo of tomonagura and base stone is used.

Last edited by mainaman; 07-11-2017 at 08:42 PM.

Stefan

-

-

07-11-2017, 09:19 PM #19Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

I agree about the fine edge. Though I've not perfected a process, I've slurry honed similar to that video, anyway, and noticed that the edge is never harsh. I have had more opportunity to notice the difference between slurry or no slurry with tools, because you intentionally raise a wire edge on them. Edge for edge, a slurry edge holds far less wire edge and flotsam of any type than a clear water type edge as above in my picture. There's relatively little damage and foil left on the last edge I showed, but those shiny bits don't exist when I've honed with a slurry edge. The razor isn't always finer feeling, but the comfort is more predictable.

I hope someone gets a good picture of a slurried stone surface sometime before honing, and then again after honing.

The arkansas abrasives (which I am more familiar with) look more like the particles on the left, and they are quite sharp when you start something, but they dull quickly. Still, I haven't seen a tiny picture of them after dulling, either, but I suspect that the particles in an ark stone get burnished and more dull, and the voids that exist in the stones have their edges knocked off or rounded a little bit.

-

07-12-2017, 02:34 AM #20Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

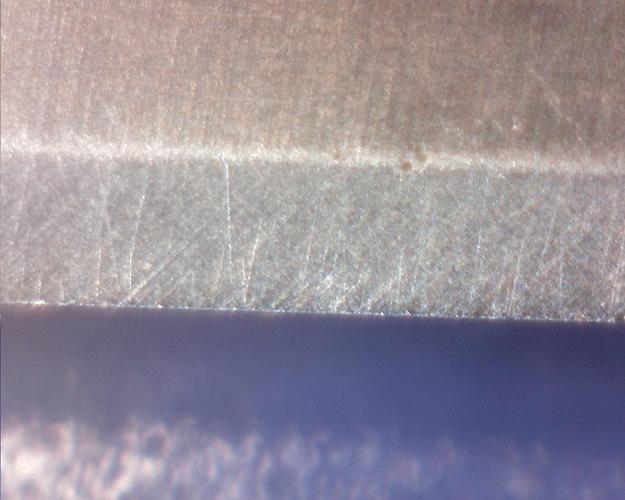

Honing with tomo, not straight off of the stone, but after linen and leather (which is probably why the edge is visible).

The scratches suggest to me that the slurry shouldn't be allowed to clear off quite as much. When I sold my first round of stones (I got out of all but suitas), I gave my tomos away with them. All I have is the tomos I made out of an ozuku stone, but I have a couple of soft finishing stones coming in the mail (small ones) to cut up and look forward to giving this another go with fresh goods.

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote